PLC hardware fault diagnosis platform constructing method

A hardware failure and fault diagnosis technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve problems such as increased automation complexity, increased equipment system failure rate, and large impact on production, so as to reduce fault processing time , Realize condition-based maintenance and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the examples.

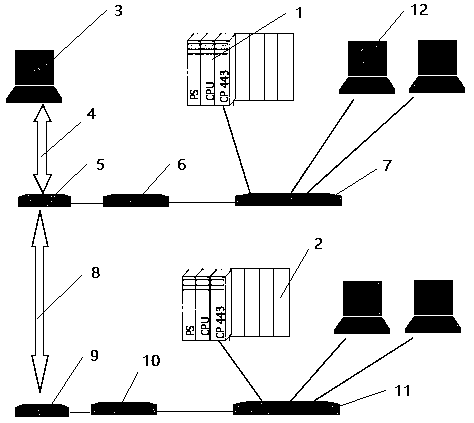

[0020] The invention discloses a method for constructing a PLC hardware fault diagnosis platform, see figure 1 , through centralized monitoring of the CPU operating status and network status of the control system, when a fault occurs, it will give an alarm in time, so that the fault point can be quickly and accurately locked, and the fault can be eliminated in time.

[0021] Specific steps are as follows:

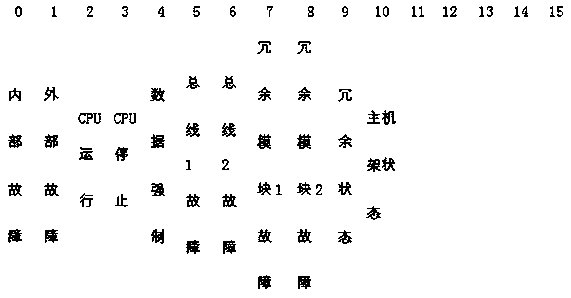

[0022] Step ① Extraction of CPU status information; in PLC system 1 and PLC system 2 2, use program instructions to extract CPU status information to form a CPU fault status word (16 bits), and each bit represents a fault status information. CPU status information includes: internal fault, external fault, bus 1 fault, bus 2 fault, redundant module 1 fault, redundant module 2 fault, data force, CPU running, CPU stop, redundancy status, main rack status, for example, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com