Double rotating disc type wet mopping mechanism, base of cleaning equipment, and cleaning equipment

A technology of cleaning equipment and double turntables, which is applied in the fields of cleaning equipment, cleaning equipment bases, and double turntable wet mopping mechanisms. It can solve problems such as damage to turntables, and achieve good cleaning effects and reasonable and effective cleaning of the floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

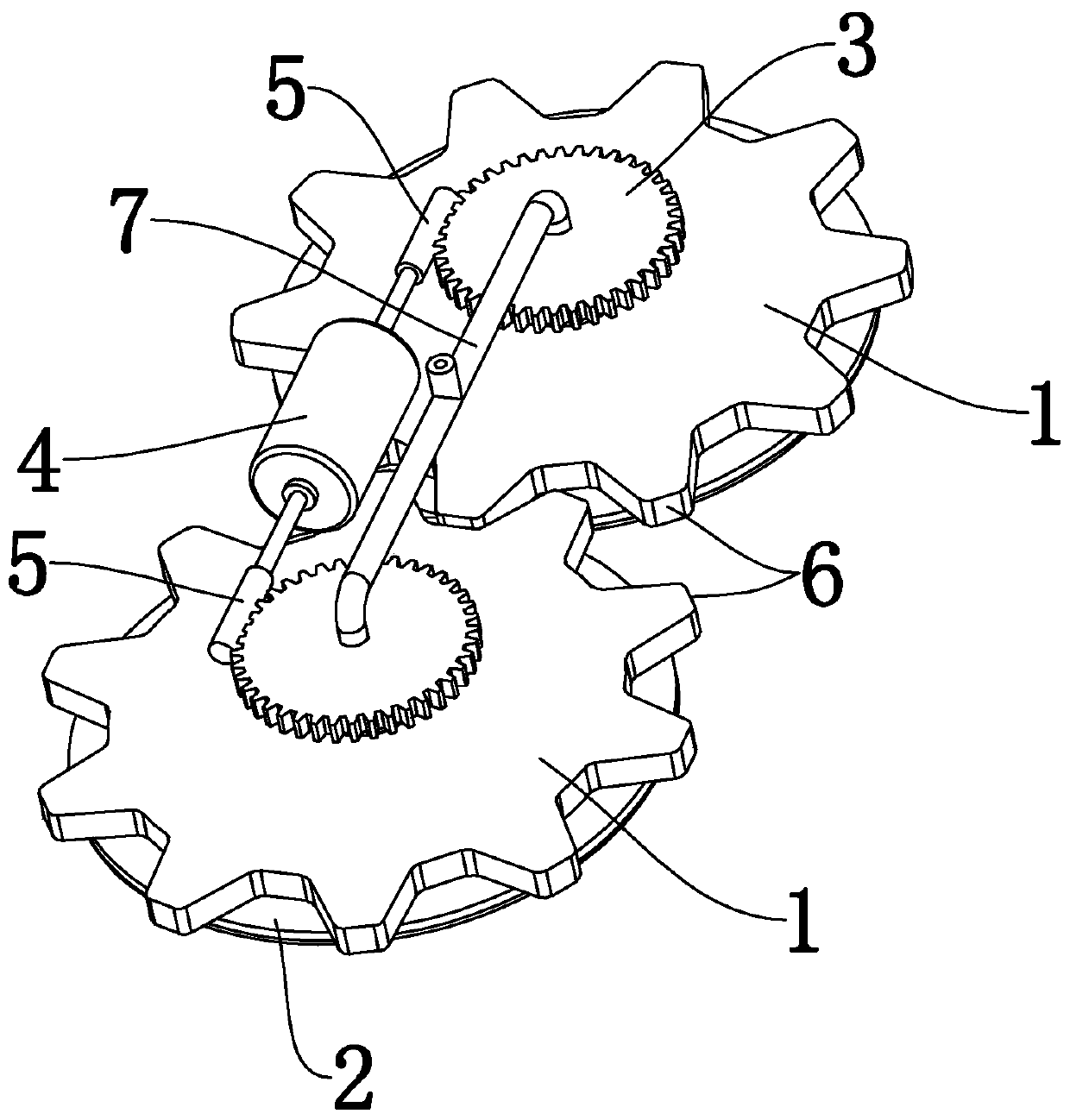

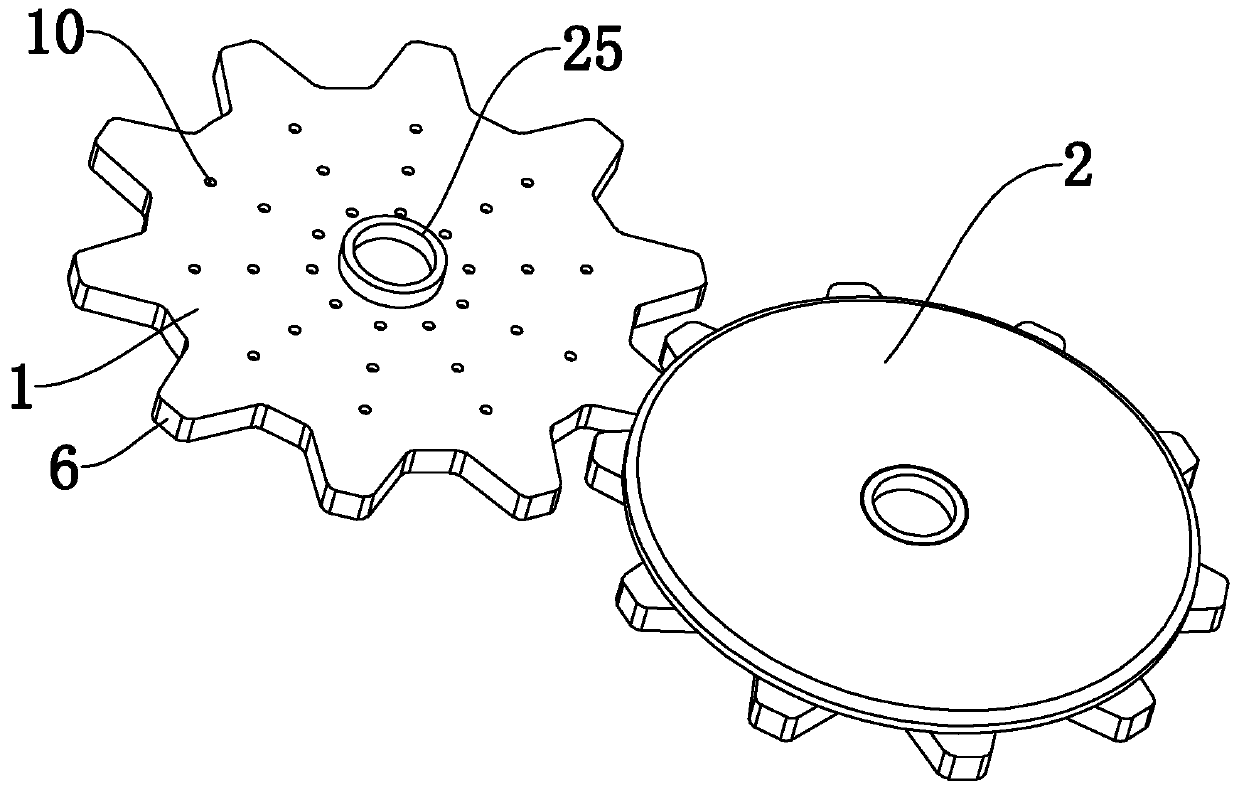

[0032] refer to figure 1 with figure 2 As shown in , the double turntable wet mopping mechanism provided in this embodiment is applied to cleaning equipment, and includes two turntables 1 arranged side by side and rotated synchronously. The bottom surface of each turntable 1 is respectively detachably installed with a mopping member 2 , and the outer edges of the two turntables 1 have auxiliary structures for pushing the mop 2 down against the ground.

[0033] Based on the above technical solution, the double turntable 1-type wet mopping mechanism includes two turntables 1 and mopping parts 2, and the outer edge of the turntable 1 has an auxiliary structure, which can effectively press the mopping parts 2 down against the ground to solve the dragging blind spot The problem.

[0034] In a preferred embodiment, the auxiliary structure is a tooth-shaped structure 6 formed by extending outward from the outer edge of the turntable 1 , and the tooth-like structures 6 of the two t...

Embodiment 2

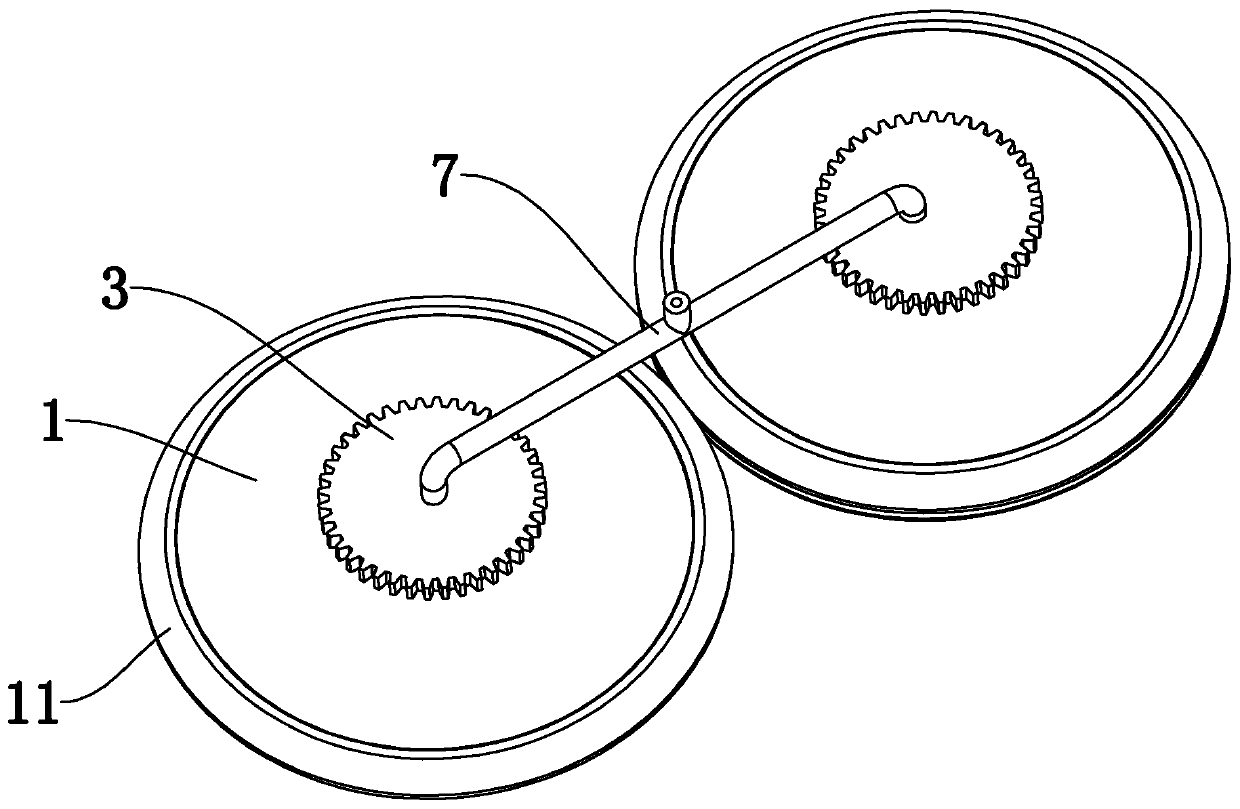

[0039] refer to image 3 with Figure 4 As shown in , the structure and content of the double turntable wet mopping mechanism provided by this embodiment are basically the same as the first embodiment above, the only difference is that the above auxiliary structure is clamped on the outer edge of the turntable 1 and made of rubber material Or a ring sleeve 11 made of soft PVC plastic material, and the outer edges of the ring sleeves 11 of the two turntables 1 are tangent. It can also play the effect of pressing the mopping member 2 downward against the ground. Further, in this embodiment, the outer periphery of the turntable 1 has an annular flange, and the inner periphery of the ring sleeve 11 has an annular groove matching the structure of the annular flange. In addition, the mopping member 2 is a disposable mop or a rewashable mop.

Embodiment 3

[0041] refer to Figure 5 to Figure 8 As shown in , the base of the cleaning equipment provided in this embodiment includes a base body 23, a dust suction mechanism set on the base body 23, a dry mopping mechanism, and a double-turntable wet mopping mechanism as described in Embodiment 1 or Embodiment 2 above. mopping mechanism, and the dust suction mechanism, double-rotary wet mopping mechanism, and dry mopping mechanism are arranged in the base body 23 from front to back in sequence, and the functional parts of the dust suction mechanism, double-rotary wet mopping mechanism, and dry mopping mechanism are all set at the bottom of the base body 23 .

[0042] Based on the above technical solution, the base of the cleaning device includes a base body 23, a dust suction mechanism, a double-rotary wet mopping mechanism, and a dry mopping mechanism, so that the operations of vacuuming, wet mopping, and dry mopping can be completed at one time during the use of the cleaning equipmen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap