Wooden door surface pit filling device

A technology for wooden doors and partitions, applied in irregularity removal devices, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of workshop environment, low efficiency, easy deterioration and odor of pig blood ash, etc. Achieve the effect of complete crushing and speed up crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

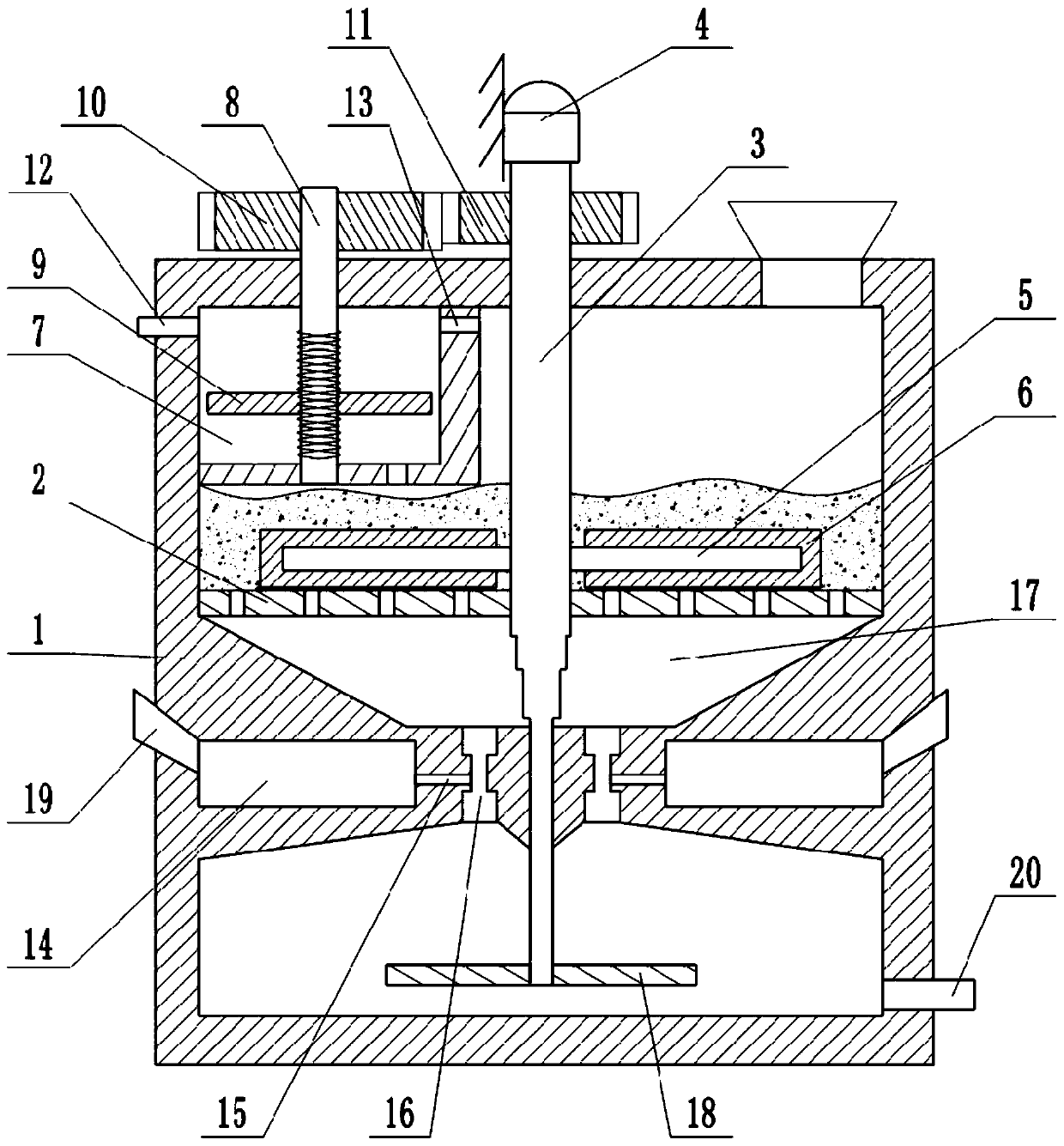

[0032] Basic as attached figure 1 Shown: The wooden door surface leveling device includes a frame and a feeding mechanism. The feeding mechanism includes a mixing bucket 1, which is fixed on the frame by bolts. The plate 2 and the separating plate 2 are provided with sieve holes, where the separating plate 2 selects a copper sieve with 180 meshes (corresponding to an aperture of 83 μm). The upper side of the partition plate 2 is the blood clot crushing area. The top of the mixing bucket 1 is also connected with a vertically arranged stirring shaft 3 through bearing rotation, the upper end of the stirring shaft 3 is fixedly clamped with the output shaft of the motor 4, and the motor 4 is fixed to the frame by bolts; There is a first stirring part, the first stirring part is located in the blood clot crushing area, the first stirring part includes a rotating shaft 5 and a stirring roller 6, the stirring shaft 3 has a through hole in the radial direction, the rotating shaft 5 ru...

Embodiment 2

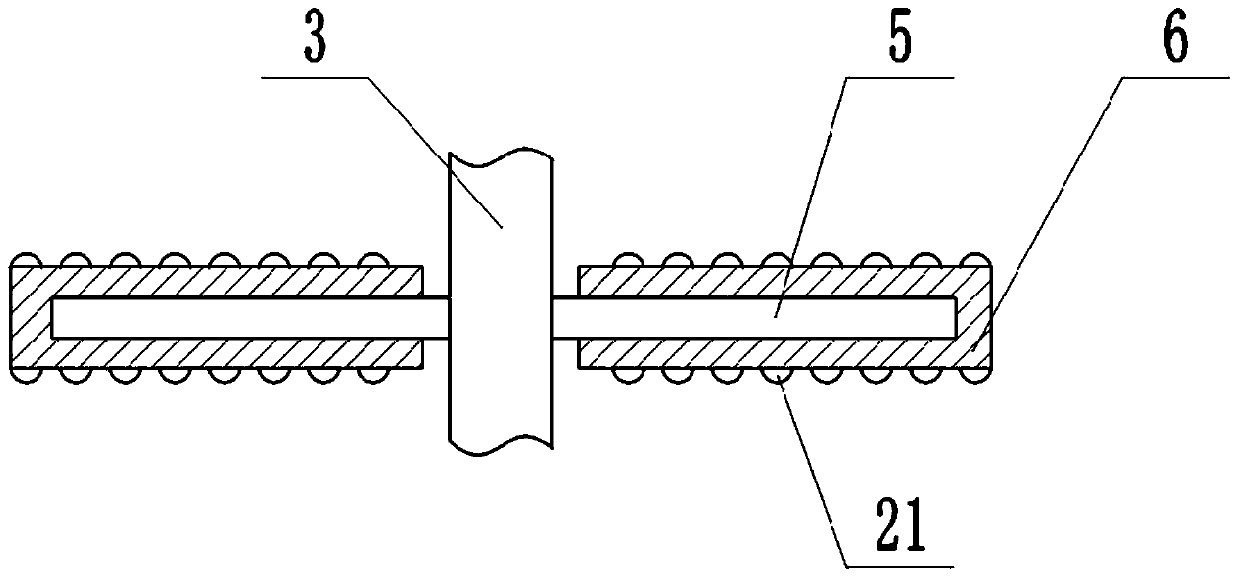

[0042] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the outer peripheral surface of the stirring roller 6 is bonded with a protrusion 21, and when the protrusion 21 rotates to the lower side of the stirring roller 6, it is against the partition plate 2. The protrusion here 21 select the rubber material with bigger frictional force to make for use. When using this solution, the frictional force between the stirring roller 6 and the partition plate 2 is increased, so that the stirring roller 6 rotates around the rotating shaft 5 more stably, and then the stirring roller 6 can crush and crush the pig blood clot, which accelerates the pig blood clot crushing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com