Vacuum evaporation substrate and vacuum evaporation device

A substrate and evaporation technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem that the opening area cannot be accurately aligned, and achieve the effect of ensuring the evaporation effect and improving the degree of sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

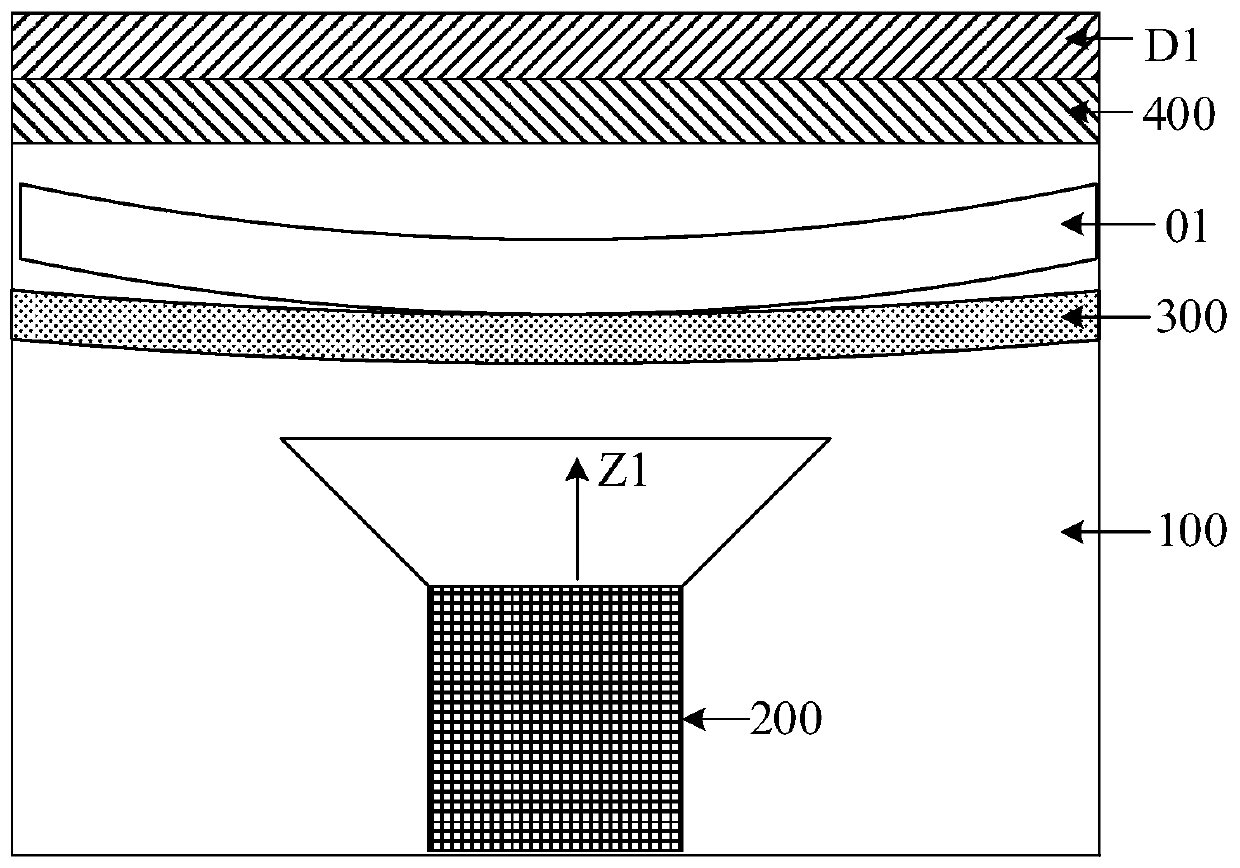

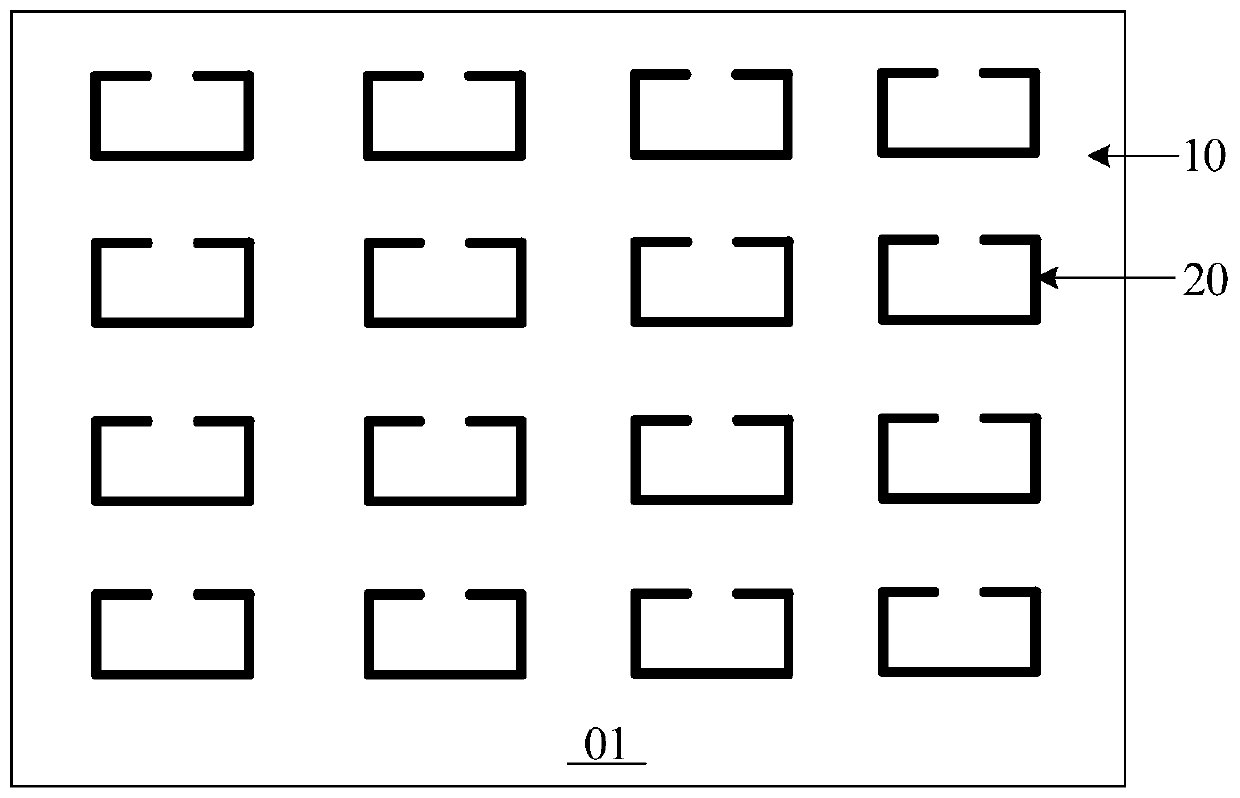

[0037] figure 1 It is a structural schematic diagram of an evaporation equipment provided by an embodiment of the present invention. Such as figure 1 As shown, the evaporation equipment may include: an evaporation chamber (equipment chamber, EQP chamber) 100, and an evaporation source (source) 200, a mask (mask) 300 and a magnetic mechanism located in the evaporation chamber 100 (magnet) 400. The mask plate 300 and the magnetic mechanism 400 can be arranged in sequence along the emission direction Z1 away from the evaporation source 200 , and the magnetic mechanism 400 can be fixed on the top D1 of the evaporation chamber 100 . Optionally, the mask 300 may be a high-precision metal mask (fine metal mask, FFM).

[0038] Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com