Online evaluation method for air feeder state of power plant

A technology for blowers and power plants, applied in engine functions, engine control, machines/engines, etc., can solve the problems of low calculation accuracy, inconsistent analysis results, and high sampling frequency of spectrum analysis methods, so as to reduce the requirements of maintenance personnel and ensure calculation. Accuracy and the effect of ensuring the rapidity of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

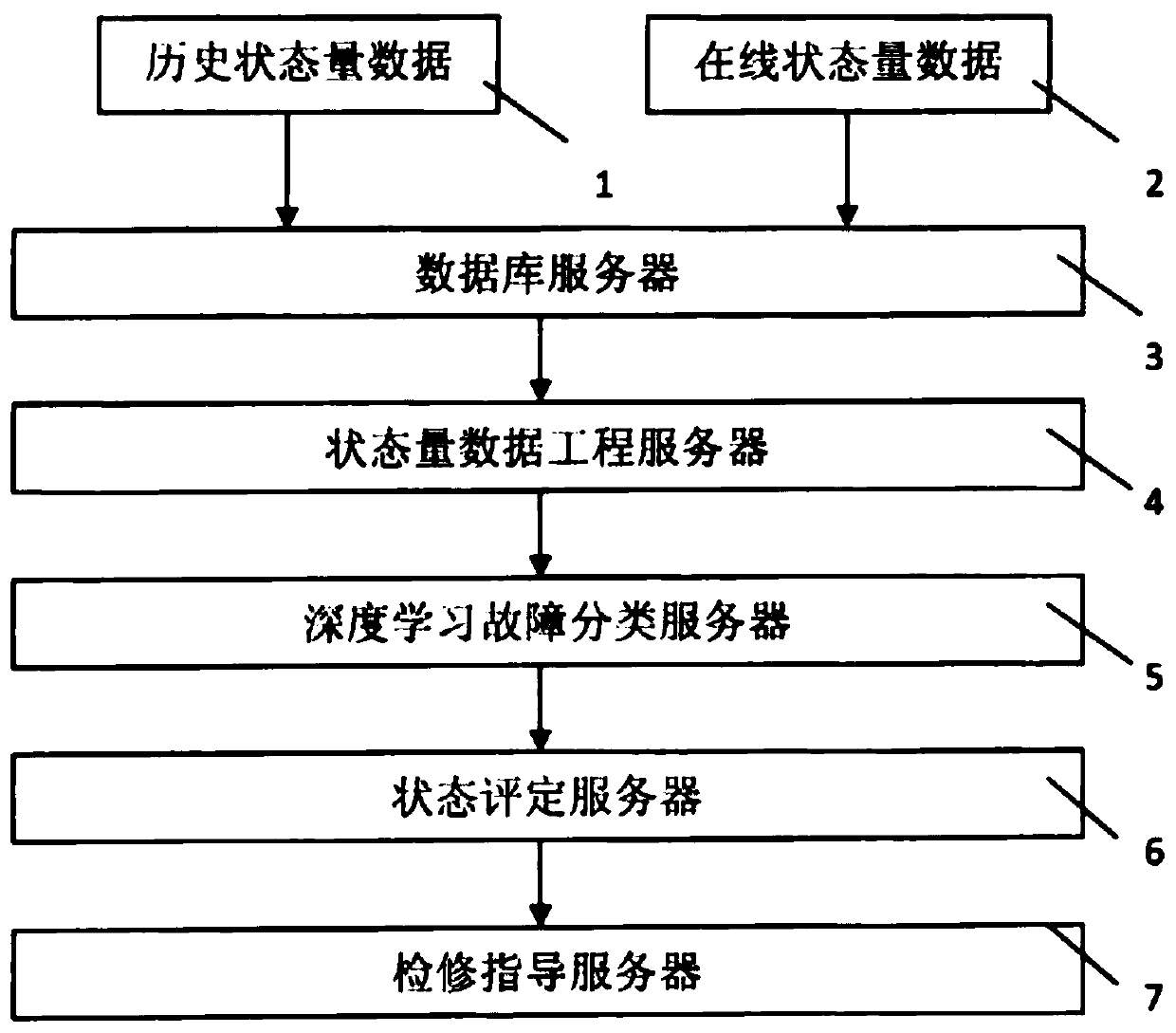

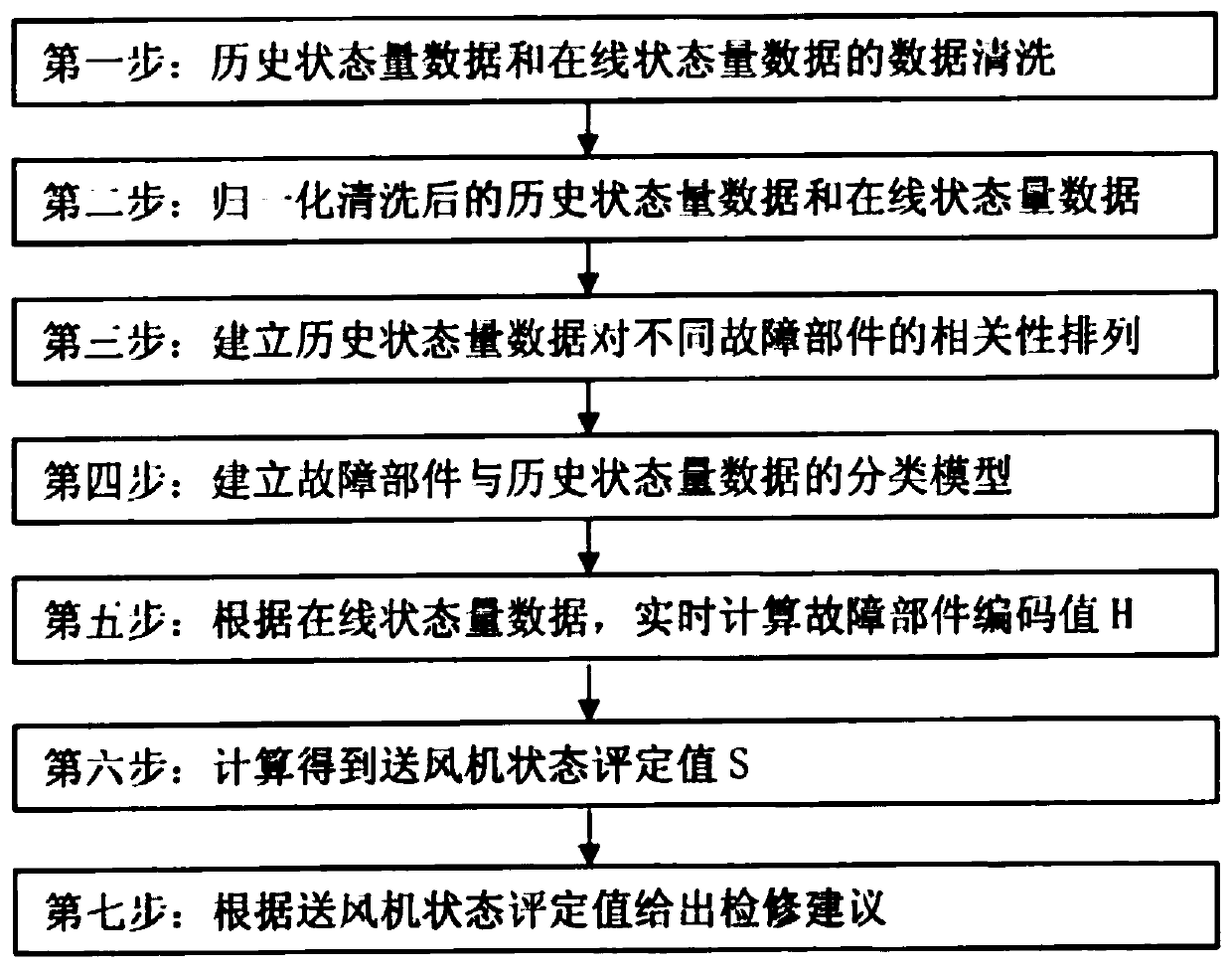

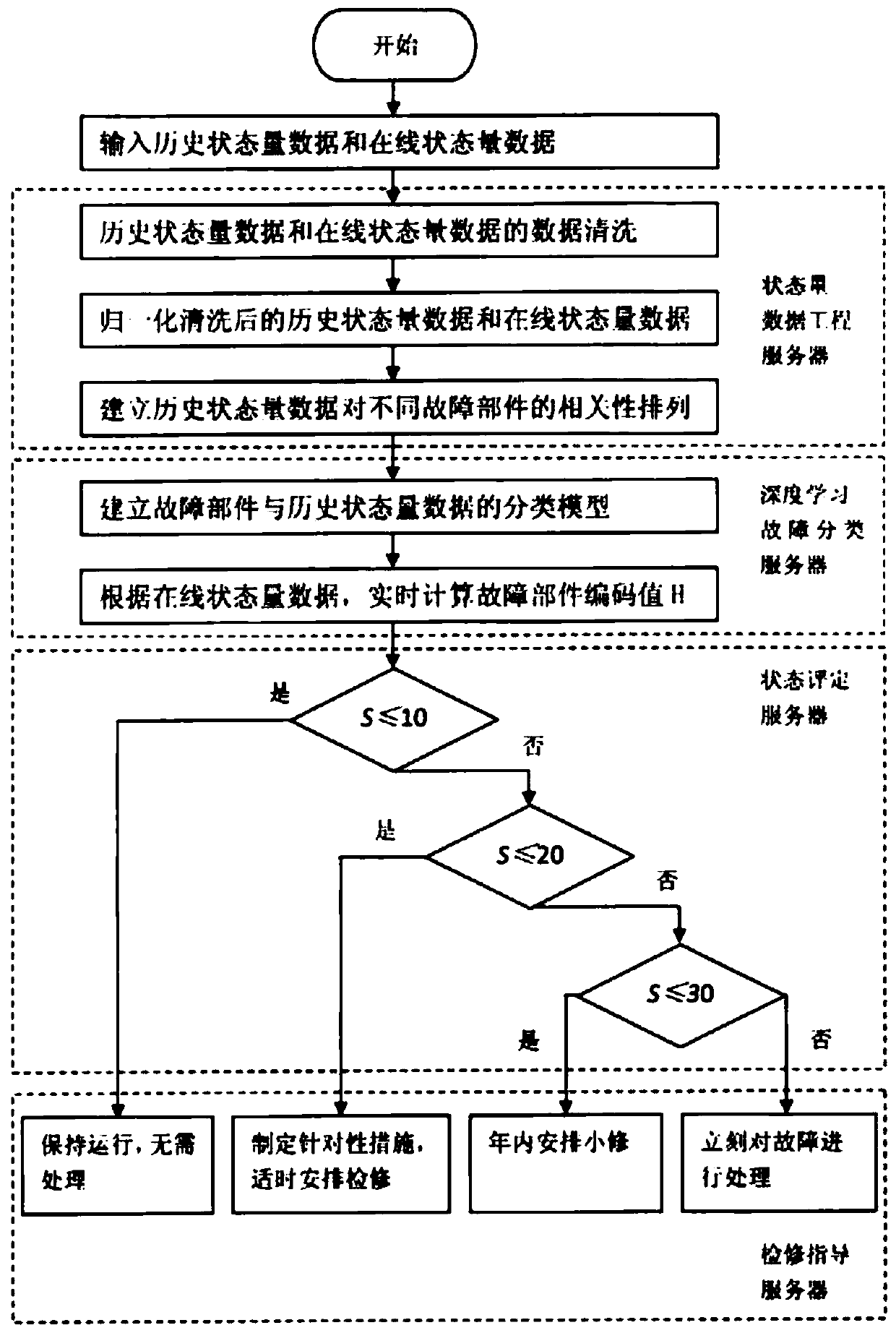

[0046] For a certain type of blower, during the service period of the blower, use figure 1 the device shown, figure 2 The flowchart shown, image 3 The computer software shown and Figure 4 According to the fault code and hazard table shown in the table, during the operation, it was found that the blower had vibration and noise.

[0047] Step 1: Enter the online state quantity data into the state quantity data engineering server to complete data cleaning;

[0048] Step 2: After cleaning the online state quantity data, normalize it;

[0049] Step 3: Input the normalized online state quantity data into the deep learning fault classification server, and use the classification model of faulty components and historical state quantity data to input the state quantity data of the above steps into the classification model for calculation.

[0050] Step 4: Calculate the code value H of the faulty component of the blower 0 =1.26, according to the calculation formula H=Round(1.26)=...

Embodiment 2

[0054] For a certain type of blower, during the service period of the blower, use figure 1 the device shown, figure 2 The flowchart shown, image 3 The computer software shown and Figure 4 According to the fault code and hazard degree table shown, it is found that the temperature of the blower bearing has risen during operation.

[0055] Step 1: Enter the online state quantity data into the state quantity data engineering server to complete data cleaning;

[0056] Step 2: After cleaning the online state quantity data, normalize it;

[0057] Step 3: Input the normalized online state quantity data into the deep learning fault classification server, and use the classification model of faulty components and historical state quantity data to input the state quantity data of the above steps into the classification model for calculation.

[0058] Step 4: Calculate the code value H of the faulty component of the blower 0 =1.91, according to the calculation formula H=Round(1.91)...

Embodiment 3

[0062] For a certain type of blower, during the service period of the blower, use figure 1 the device shown, figure 2 The flowchart shown, image 3 The computer software shown and Figure 4 According to the fault code and hazard degree table shown, during the operation, it is found that a slight metal friction sound can be heard at the casing of the blower.

[0063] Step 1: Enter the online state quantity data into the state quantity data engineering server to complete data cleaning;

[0064] Step 2: After cleaning the online state quantity data, normalize it;

[0065] Step 3: Input the normalized online state quantity data into the deep learning fault classification server, and use the classification model of faulty components and historical state quantity data to input the state quantity data of the above steps into the classification model for calculation.

[0066] Step 4: Calculate the code value H of the faulty component 0 =3.17, according to the calculation formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com