Testing device and method for mechanical and fluid flow performance of pipe-in-pipe system

A technology of system mechanics and fluid flow, applied in the direction of measuring devices, instruments, etc., can solve problems such as the inability to provide effective guarantee for the safety assessment of "pipe-in-pipe system" and the inability to fully simulate the influence of pipe and pipe string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

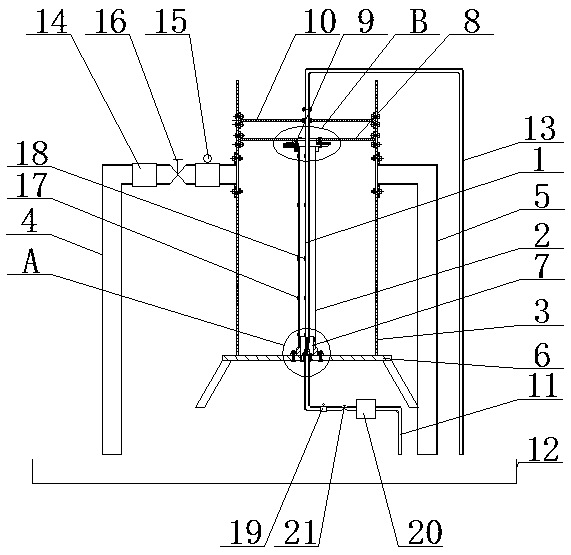

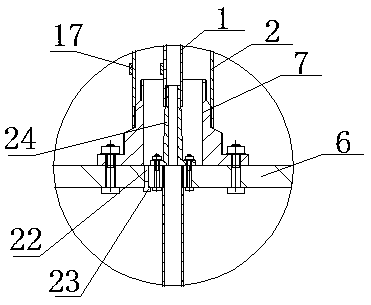

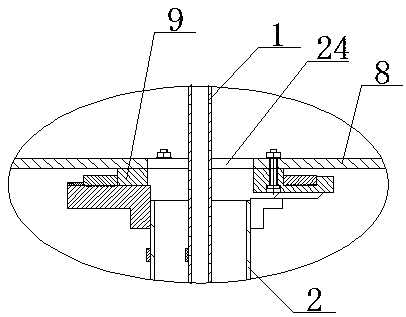

[0034] The pipe-in-pipe system mechanical and fluid flow performance testing device includes an inner pipe 1 , an outer pipe 2 , a test cylinder 3 , a cylinder water inlet pipe 4 , a discharge pipe 5 and a base 6 . The test cylinder 3 is sealed and welded on the base 6, and the outer pipe 2 is threadedly installed in the test cylinder 3 through the outer pipe adapter 7 fixed on the base 6, and the inner pipe adapter 7 is provided with an inner pipe adapter 24; the base 6 between the outer pipe adapter 7 and the inner pipe adapter 24 is provided with a discharge hole 22, and the thread on the discharge hole 22 is equipped with a plug 23, and the discharge hole 22 is connected to the outer pipe adapter 7 through the outer pipe adapter 24. Tube 2 communicates. The test cylinder 3 at the top of the outer tube 2 is sealed and installed with a top cover 8 through fixing bolts, and the outer tube 2 is sealed and fixedly connected with the lower surface of the top cover 8 through a ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap