Water soluble compositions comprising purified cannabinoids

A technology of cannabinoids and compositions, applied in the field of cannabis industry, can solve problems such as uncontrollable and difficult to control cannabinoids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

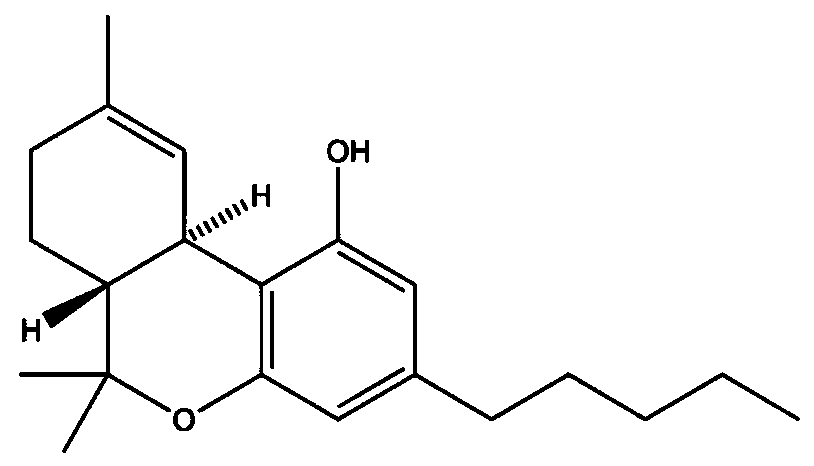

Embodiment 1

[0270] THC was purified from Cannabis by chromatography to yield a clear yellowish oil. The weight of the oil was 5.00 g. In a separate container weigh out 20.0 g Vitamin E TPGS. The two compounds were combined in a container with 50 mL of water. The solution was sonicated for 15-20 minutes until a homogeneous mixture was formed.

[0271] The solution was transferred to a tray forming a thin layer with a depth of about 2 cm. The trays were then placed in the refrigerator for 8 hours to produce solid pieces. The solid pieces were placed in a plastic bag and vacuum sealed under reduced pressure for 1 hour. Remove the tray from the bag and place in the oven for 1 hour. The tray was cooled to ambient temperature and the thin layer was scraped off using a spatula to obtain a powder. If agglomeration occurs, use a mortar and pestle to create a finer powder. The micelles were measured using a refractometer.

Embodiment 2

[0273] CBD is purified from Cannabis plants by chromatography, yielding a clear yellowish oil. The weight of the oil was 5.00 g. In a separate container weigh out 20.0 g Vitamin E TPGS. The two compounds were combined in a container with 50 mL of water. The solution was sonicated for 15-20 minutes until a homogeneous mixture was formed.

[0274] The solution was transferred to a tray forming a thin layer with a depth of about 2 cm. The trays were then placed in the refrigerator for 8 hours to produce solid pieces. The solid pieces were placed in a plastic bag and vacuum sealed under reduced pressure for 1 hour. Remove the tray from the bag and place in the oven for 1 hour. The tray was cooled to ambient temperature and the thin layer was scraped off using a spatula to obtain a powder. If agglomeration occurs, use a mortar and pestle to create a finer powder. The micelles were measured using a refractometer.

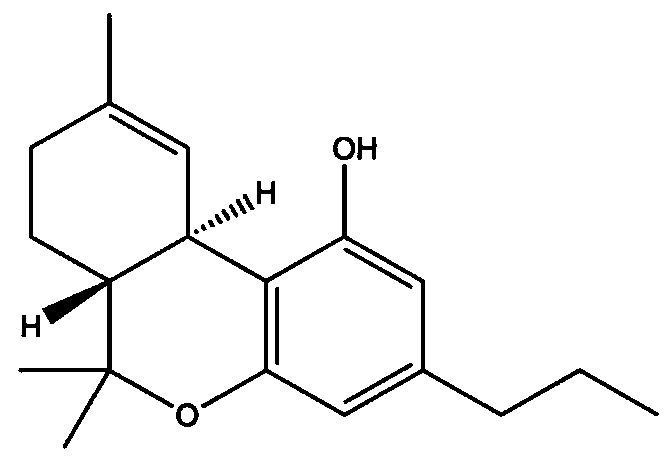

Embodiment 3

[0276] THCV was purified from Cannabis by chromatography to yield a clear yellowish oil. The weight of the oil was 5.00 g. In a separate container weigh out 20.0 g Vitamin E TPGS. The two compounds were combined in a container with 50 mL of water. The solution was sonicated for 15-20 minutes until a homogeneous mixture was formed.

[0277] The solution was transferred to a tray forming a thin layer with a depth of about 2 cm. The trays were then placed in the refrigerator for 8 hours to produce solid pieces. The solid pieces were placed in a plastic bag and vacuum sealed under reduced pressure for 1 hour. Remove the tray from the bag and place in the oven for 1 hour. The tray was cooled to ambient temperature and the thin layer was scraped off using a spatula to obtain a powder. If agglomeration occurs, use a mortar and pestle to create a finer powder. The micelles were measured using a refractometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com