Automatic sprouting vegetable harvesting device

An automatic technology for sprouts, applied to harvesters, transportation and packaging, conveyor objects, etc., can solve the problems of affecting the harvesting process, wasting manpower and material resources, and labor costs, so as to reduce processing procedures, increase production efficiency, Convenient post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

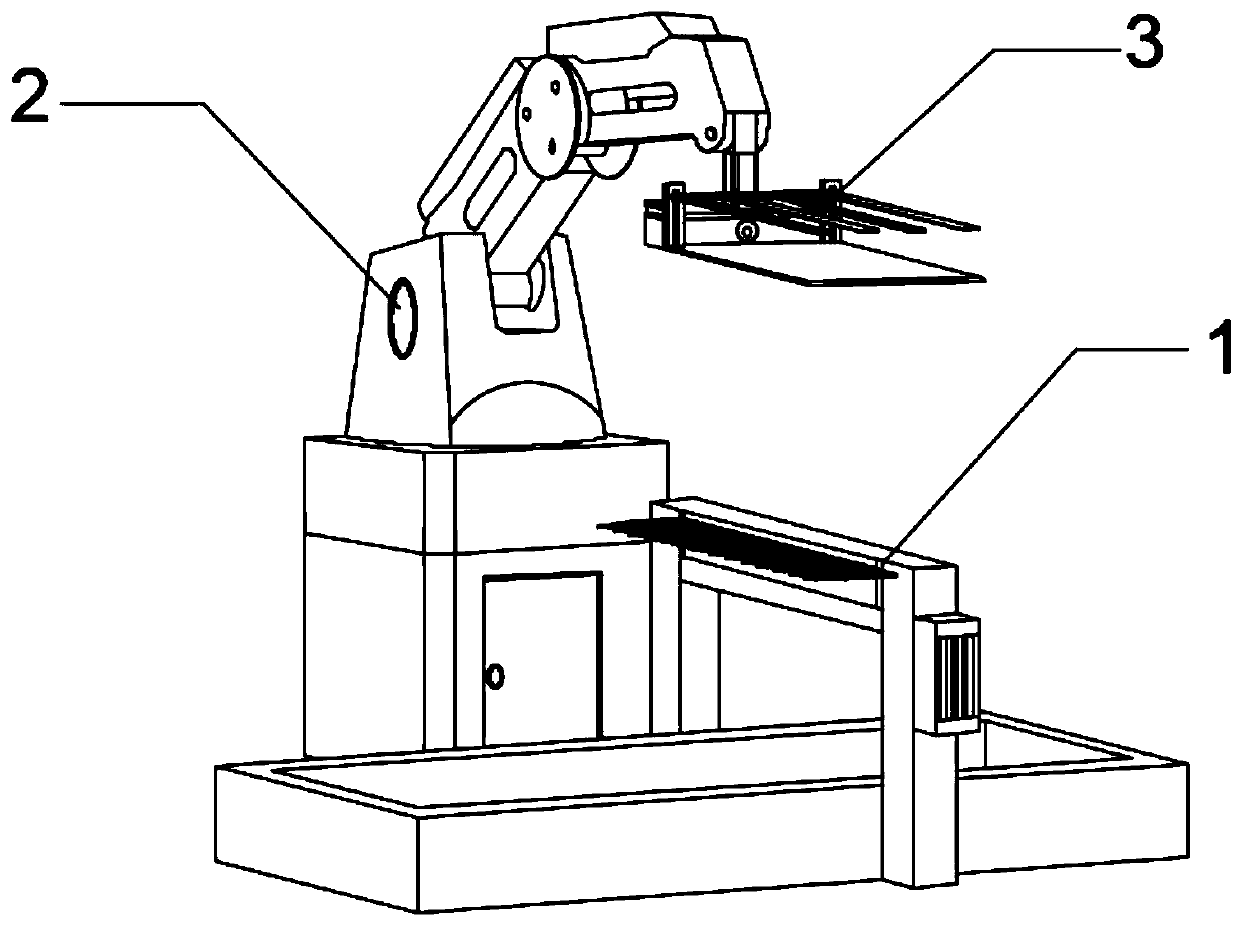

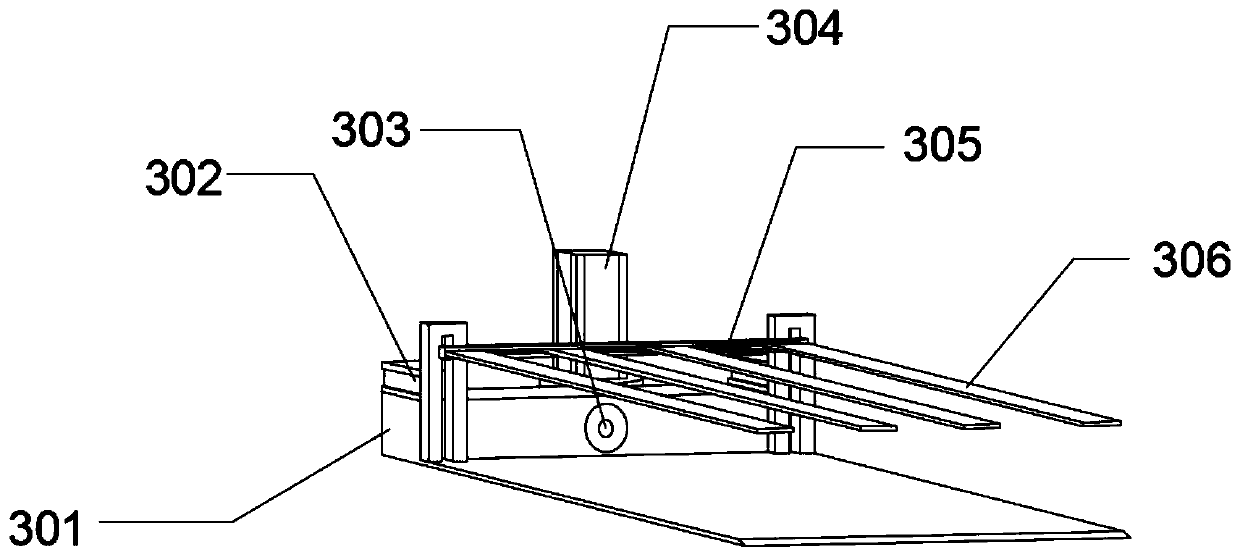

[0031] see Figure 1-Figure 5 , a device for automatic harvesting of sprouts in the present embodiment, comprising a manipulator picking mechanism and a cutting mechanism 1. A disk mechanism 3, the chuck mechanism 3 is arranged on the mechanical arm 2, and the mechanical arm 2 can drive the chuck mechanism 3 to rotate at multiple angles. The cutting mechanism 1 is a fixed cutting mechanism 101 or a moving cutting mechanism, and the moving cutting mechanism includes a horizontal moving type 102 and a vertical moving type 103 .

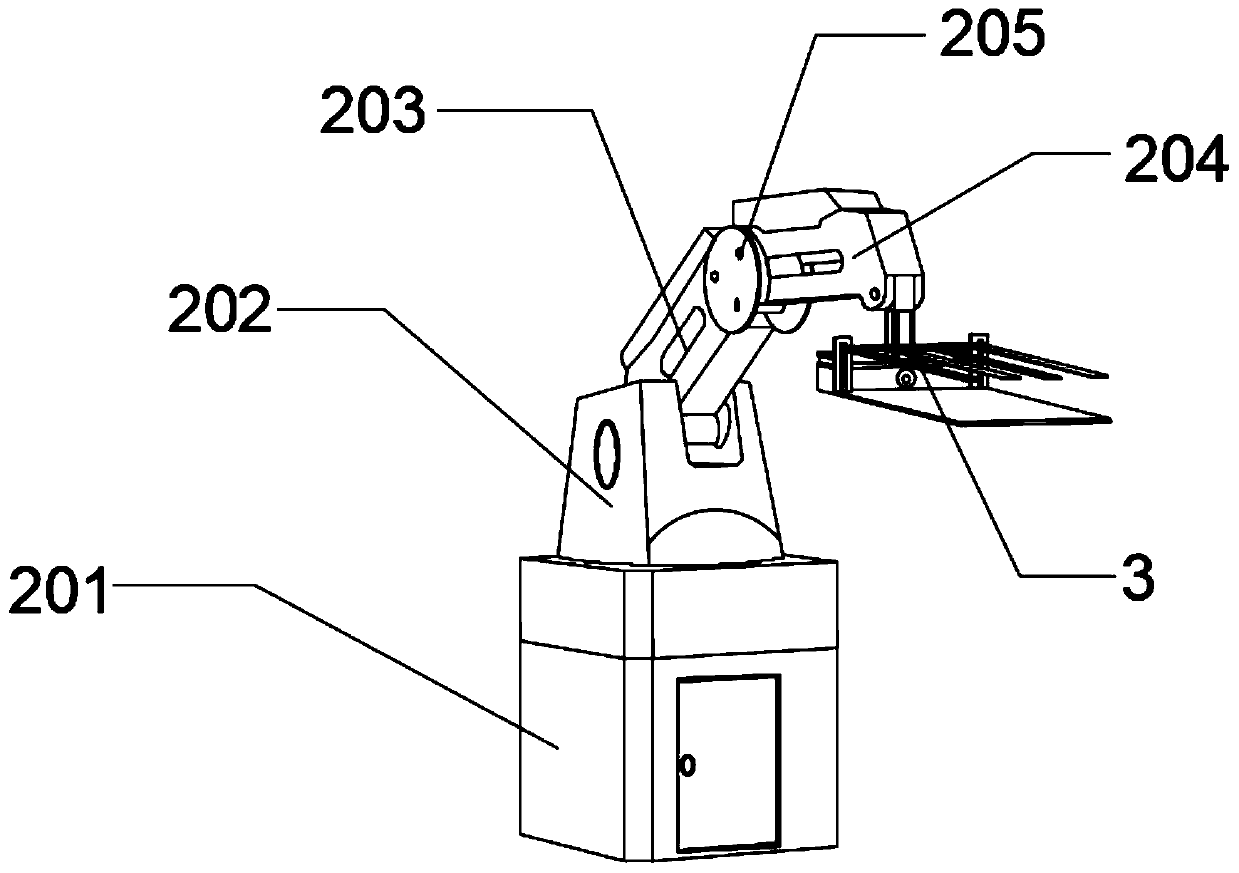

[0032] In this embodiment, the mechanical arm 2 includes a fixed base 201, a rotating drive base 202, a first swing arm 203 and a second swing arm 204, and a motor is arranged inside the rotate drive base 202, and the drive motor 1013 is embedded Installed in the fixed base 201, the drive motor 1013 drives the rotary drive base 202 to rotate on the fixed base 201. The longitudinal section of the rotary drive base 202 is a trapezoid with a diagonal line...

Embodiment 2

[0037] see Figure 1-Figure 3 , Figure 6 , Figure 7 , a device for automatic harvesting of sprouts in the present embodiment, comprising a manipulator picking mechanism and a cutting mechanism 1. A disk mechanism 3, the chuck mechanism 3 is arranged on the mechanical arm 2, and the mechanical arm 2 can drive the chuck mechanism 3 to rotate at multiple angles. The cutting mechanism 1 is a fixed cutting mechanism 101 or a moving cutting mechanism, and the moving cutting mechanism includes a horizontal moving type 102 and a vertical moving type 103 .

[0038] In this embodiment, the mechanical arm 2 includes a fixed base 201, a rotating drive base 202, a first swing arm 203 and a second swing arm 204, and a motor is arranged inside the rotate drive base 202, and the drive motor 1013 is embedded Installed in the fixed base 201, the drive motor 1013 drives the rotary drive base 202 to rotate on the fixed base 201. The longitudinal section of the rotary drive base 202 is a trap...

Embodiment 3

[0043] see Figure 1-Figure 3 , Figure 8 , Figure 9 , a device for automatic harvesting of sprouts in the present embodiment, comprising a manipulator picking mechanism and a cutting mechanism 1. A disk mechanism 3, the chuck mechanism 3 is arranged on the mechanical arm 2, and the mechanical arm 2 can drive the chuck mechanism 3 to rotate at multiple angles. The cutting mechanism 1 is a fixed cutting mechanism 101 or a moving cutting mechanism, and the moving cutting mechanism includes a horizontal moving type 102 and a vertical moving type 103 .

[0044] In this embodiment, the mechanical arm 2 includes a fixed base 201, a rotating drive base 202, a first swing arm 203 and a second swing arm 204, and a motor is arranged inside the rotate drive base 202, and the drive motor 1013 is embedded Installed in the fixed base 201, the drive motor 1013 drives the rotary drive base 202 to rotate on the fixed base 201. The longitudinal section of the rotary drive base 202 is a trap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com