A vertical shaft impact sand making machine

A technology of vertical shaft impact and sand making machine, applied in the field of mining equipment, can solve the problems of dust pollution, large productive dust, single structure of crushing chamber assembly, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

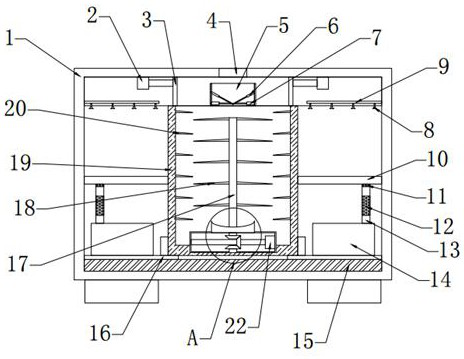

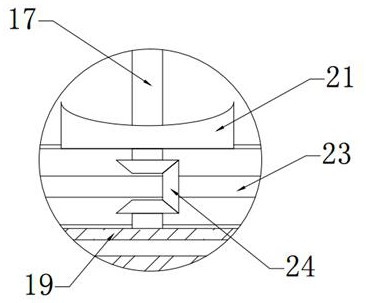

[0023] see Figure 1~3 , in an embodiment of the present invention, a vertical shaft impact sand making machine includes a shell 1, a feed port 4, a feed hopper 5 and a crushing chamber 19, the feed port 4 is arranged on the top of the shell 1, and the feed port 4 A feed hopper 5 is provided on the lower side, and a crushing chamber 19 is provided on the lower side of the feed hopper 5. The left and right sides of the bottom of the crushing chamber 19 are provided with fixed blocks 16 fixedly connected to the shell 1. The crushing chamber 19 is connected to the The fixed block 16 is slidably connected, dust removal devices are arranged on both sides of the crushing chamber 19 , and a shock absorbing pad 15 is arranged at the bottom of the fixed block 16 .

[0024] In this embodiment, the feed hopper 5 includes a first telescopic rod 2, a push plate 3, a telescopic plate 6 and a second telescopic rod 7, the telescopic plate 6 is arranged at both ends of the inner side of the fe...

Embodiment 2

[0030] A mining equipment includes the vertical shaft impact sand making machine described in Embodiment 1.

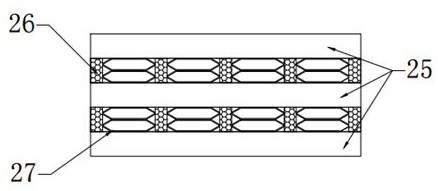

[0031] The vertical shaft impact sand making machine can realize the adjustment of the throwing material flow rate by setting the second telescopic rod 7 and the telescopic plate 6. By controlling the first telescopic rod 2, the blanking material flow rate can be adjusted. By setting the dust removal device, the system is effectively solved. The problem of excessive dust in the crushing process of the sand machine can realize the function of reducing dust. By setting the first filter layer 11 and the second filter layer 12, the purification of dust removal water can be realized, and the recycling of water resources can be realized. Through the motor 22, The shaft 17 and the crushing cavity 19 can rotate in the opposite direction, which is beneficial to improve the crushing efficiency of the sand making machine. By intersecting the metal plate 25, the elastic pad 26 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com