Spraying and carrying mechanism for vehicle trunk plates

A technology for handling mechanisms and suitcases, applied in coatings, devices for coating liquids on surfaces, etc., can solve problems such as poor versatility and difficulty in cleaning residual coatings, achieve light structure, reduce labor intensity of workers, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

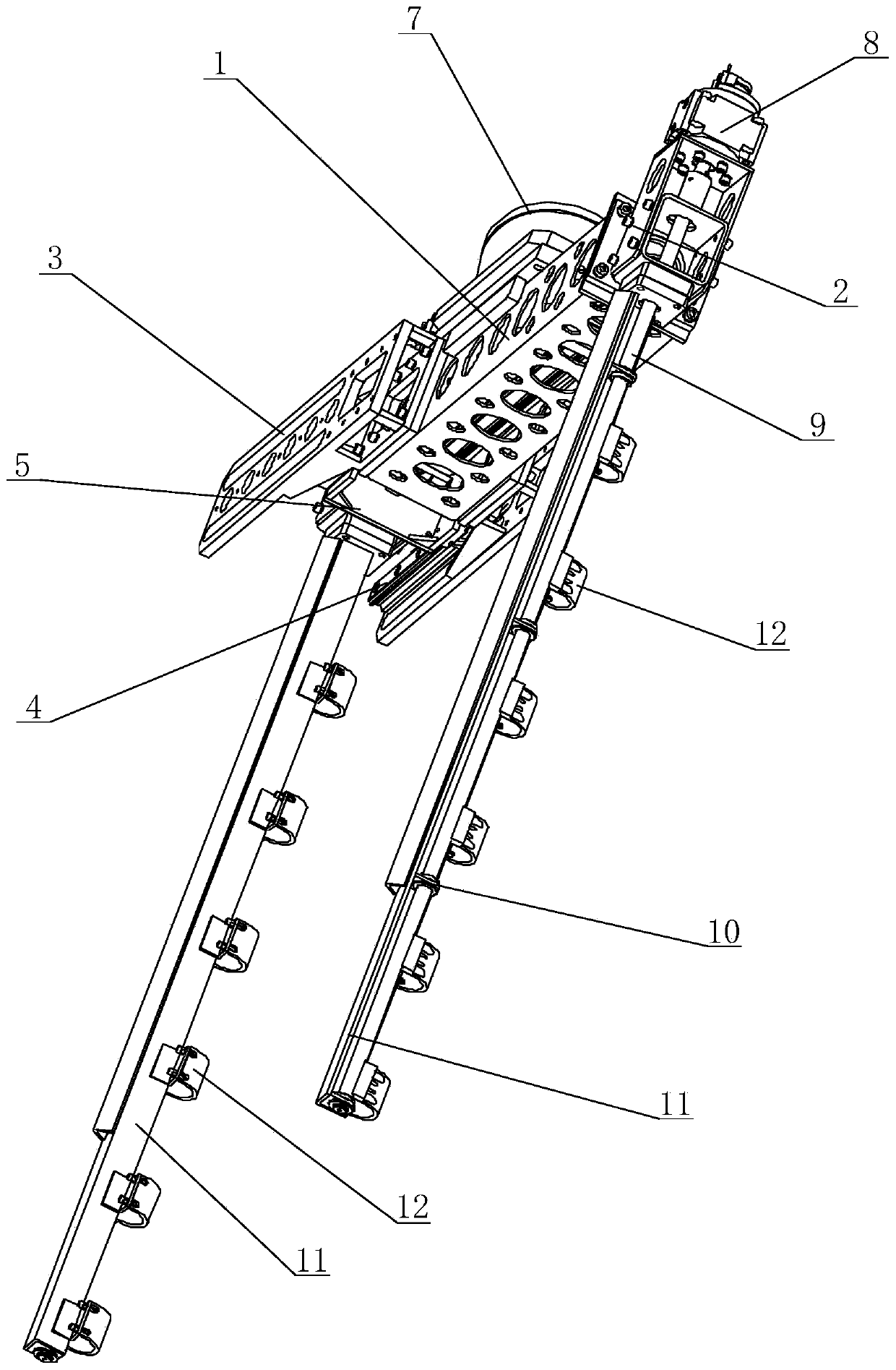

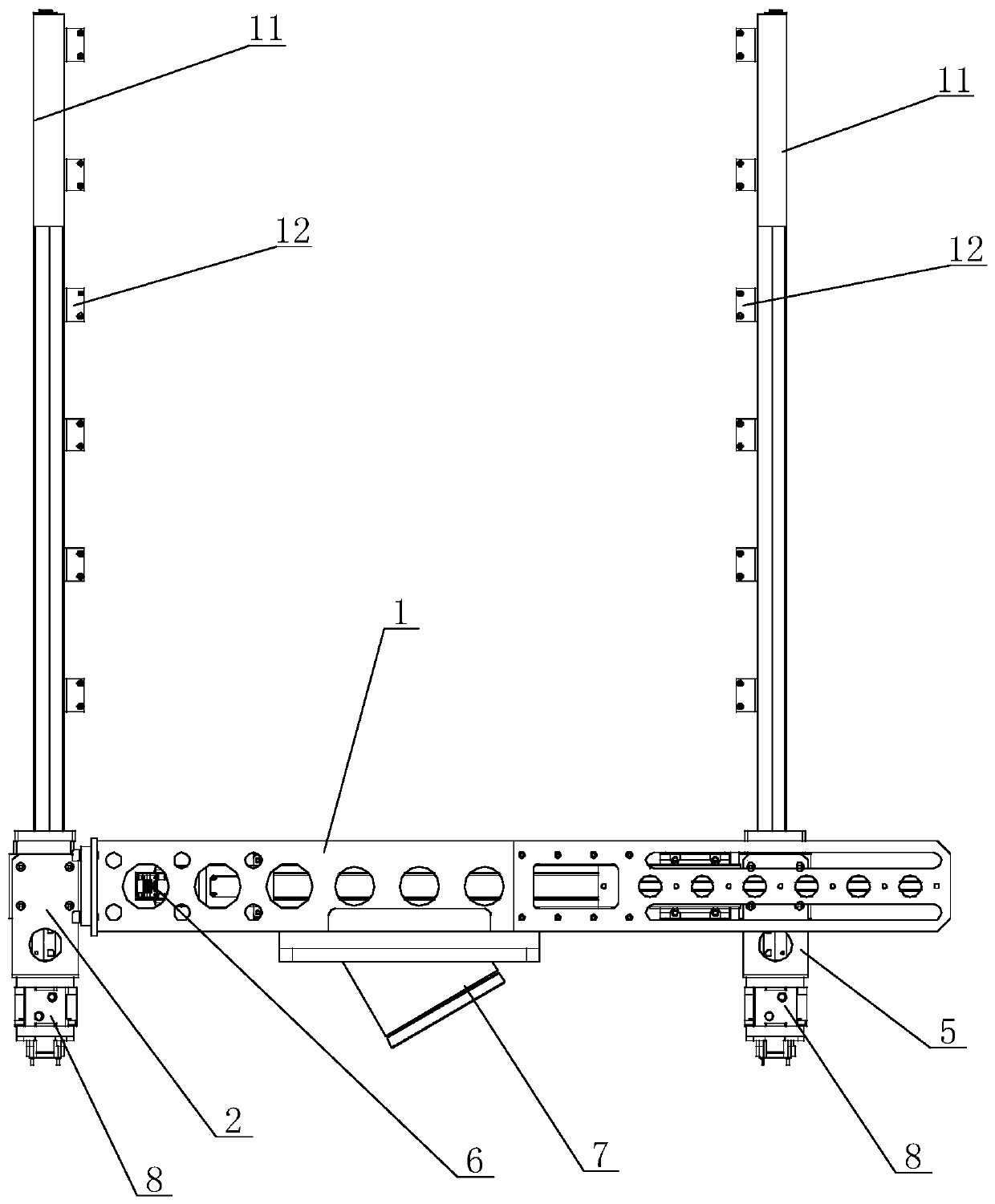

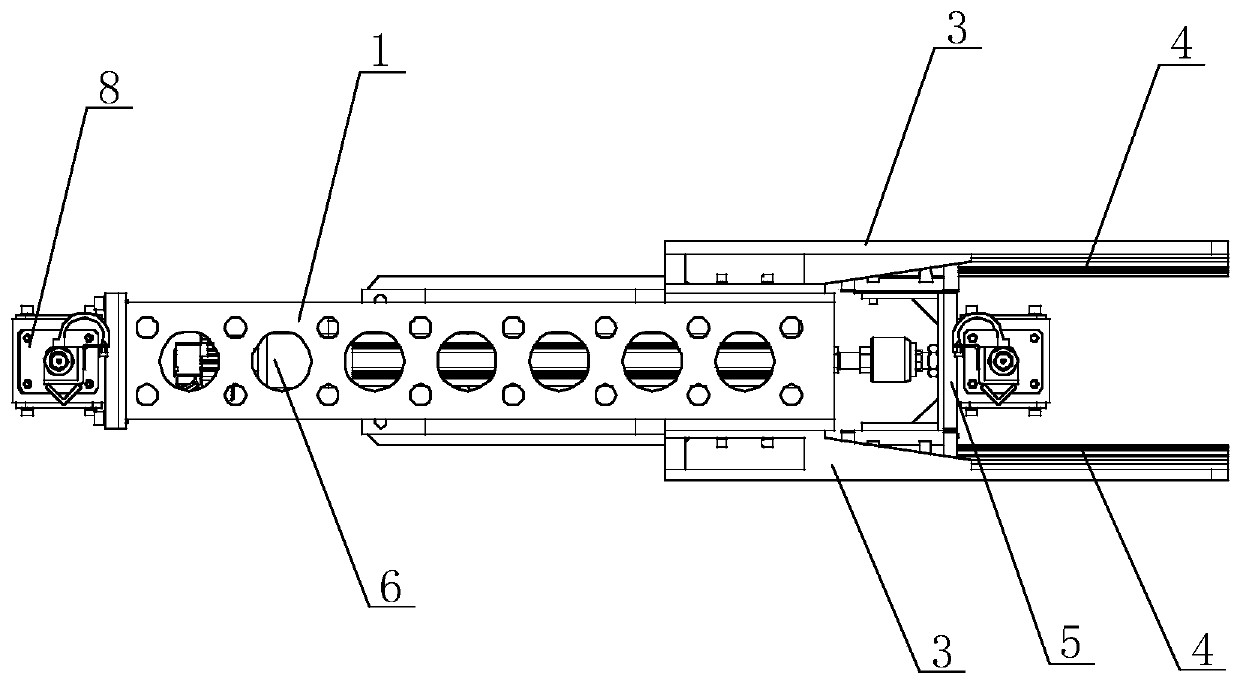

[0017] see Figure 1 to Figure 3 As shown, in this embodiment, a spraying and conveying mechanism for a spare plate of an automobile trunk includes a connecting beam 1 of a hollow structure, one end of the connecting beam 1 is connected with a mounting seat 2 through a fixing plate, and the end surface and the bottom surface of the other end are correspondingly fixed with a The mounting plate 3 extending outwards is fixed with a linear guide rail 4, and the moving seat 5 is assembled on the two linear guide rails 4 through the slider so that it can move laterally, and the interior of the connecting beam 1 is provided with a lateral movement driving cylinder 6 , traversing drive cylinder 6 is connected to moving seat 5, and connecting beam 1 is provided with a flange 7 for connecting the entire trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com