Production process applied to lantern-type riveting nut

A production process and technology for rivet nuts, applied in the direction of nuts, manufacturing tools, threaded fasteners, etc., can solve the problems of lower production yield, lower production efficiency, complex processing procedures, etc., to achieve high production efficiency and improve production efficiency , The effect of simplifying the processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

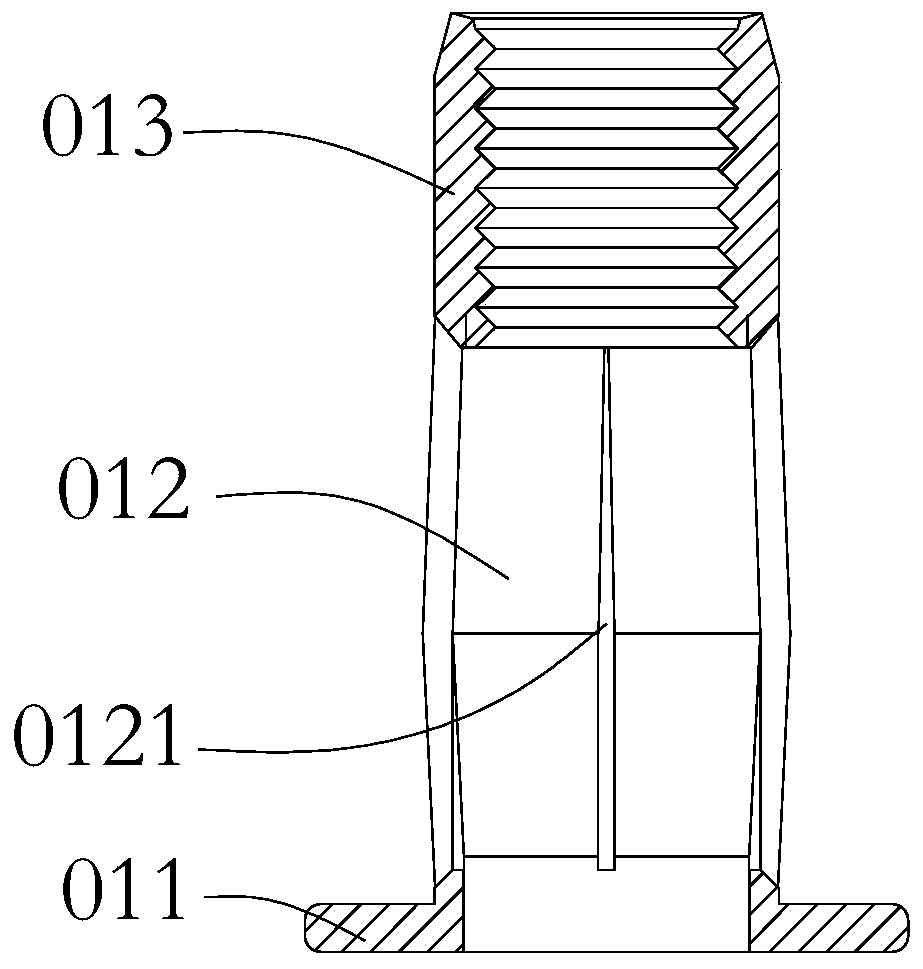

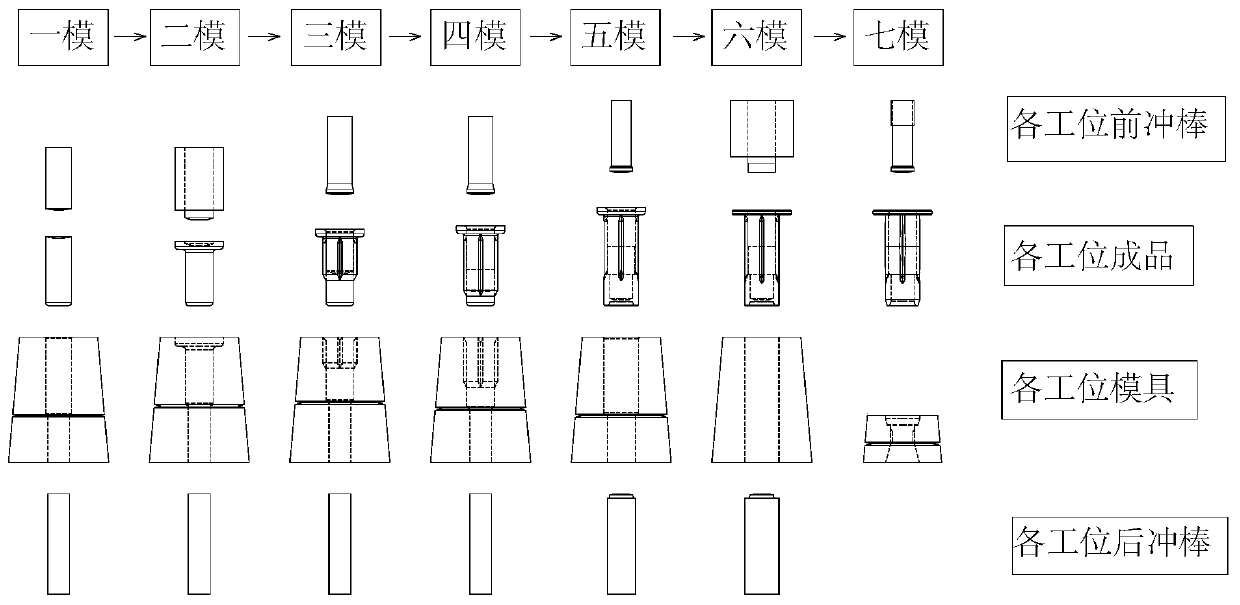

[0042] A kind of lantern-shaped rivet nut production process, with reference to figure 1 , the lantern-shaped rivet nut includes a head 011, an expansion part 012 and a threaded part 013, the head 011 and the threaded part 013 are respectively connected to the two ends of the expansion part 012, and the head 011 protrudes outward The brim body is formed, the expansion part 012 is distributed with a plurality of cracking grooves 0121 in the circumferential direction, and the lantern-shaped rivet nut is extruded on multiple mold stations, refer to figure 2 , including the following steps:

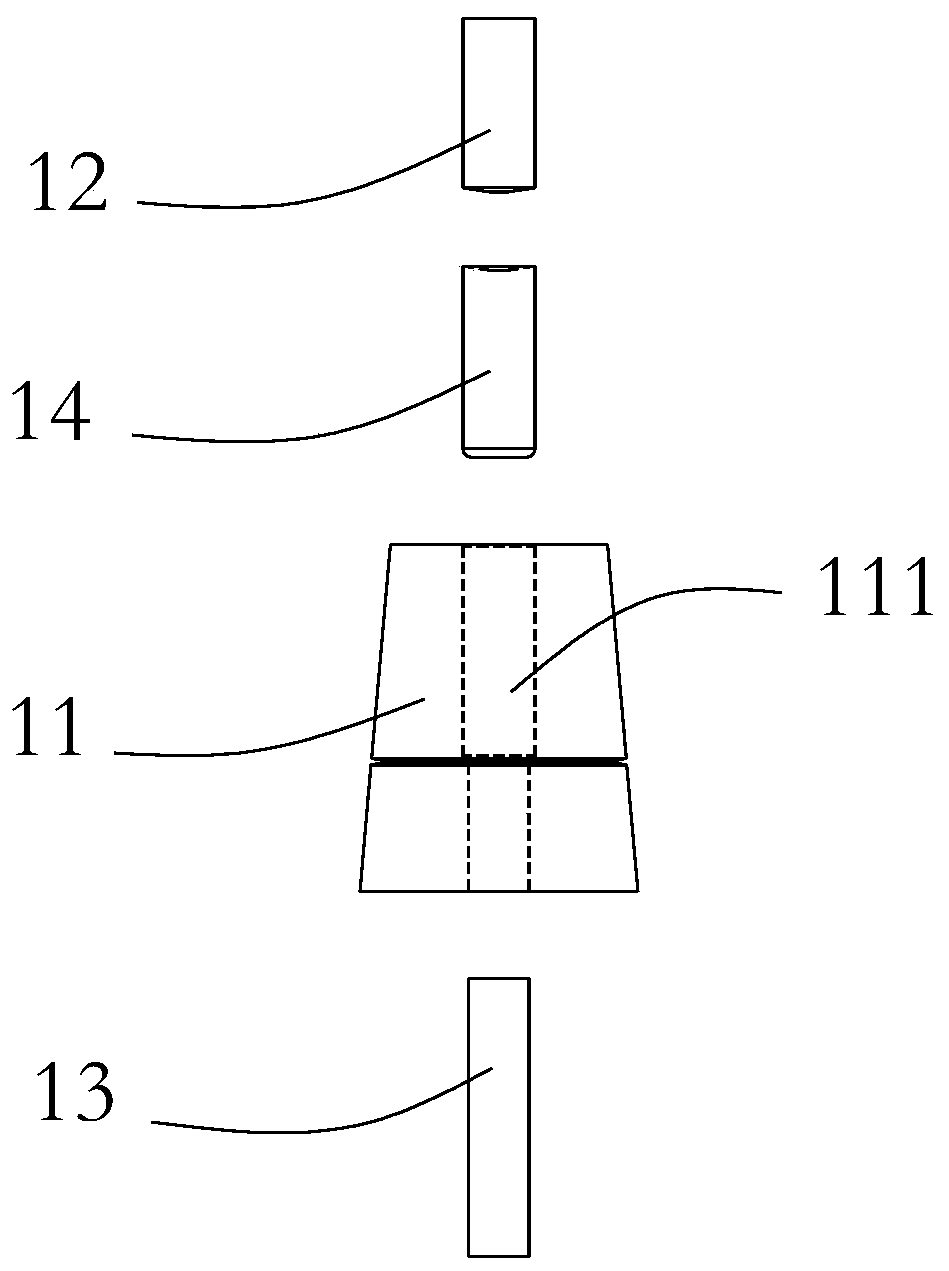

[0043] S1. One-mold integer, refer to Figure 3, the raw material is extruded into a cylinder by the first-mold front punch 12 to generate a first-mold product 14, after the extrusion is completed, the first-mold rear punch 13 pushes the first-mold prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com