Preparation method of expanded polyolefin beads, expanded polyolefin sheet and application thereof

A technology for foaming polyolefin and polyolefin resin, applied in the field of new environmental protection materials, can solve the problems of high construction difficulty, influence of sound insulation performance and thermal insulation performance, poor flame retardant performance, etc., and achieves excellent mutual fusion performance, excellent sound insulation Noise performance, the effect of improving cell stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

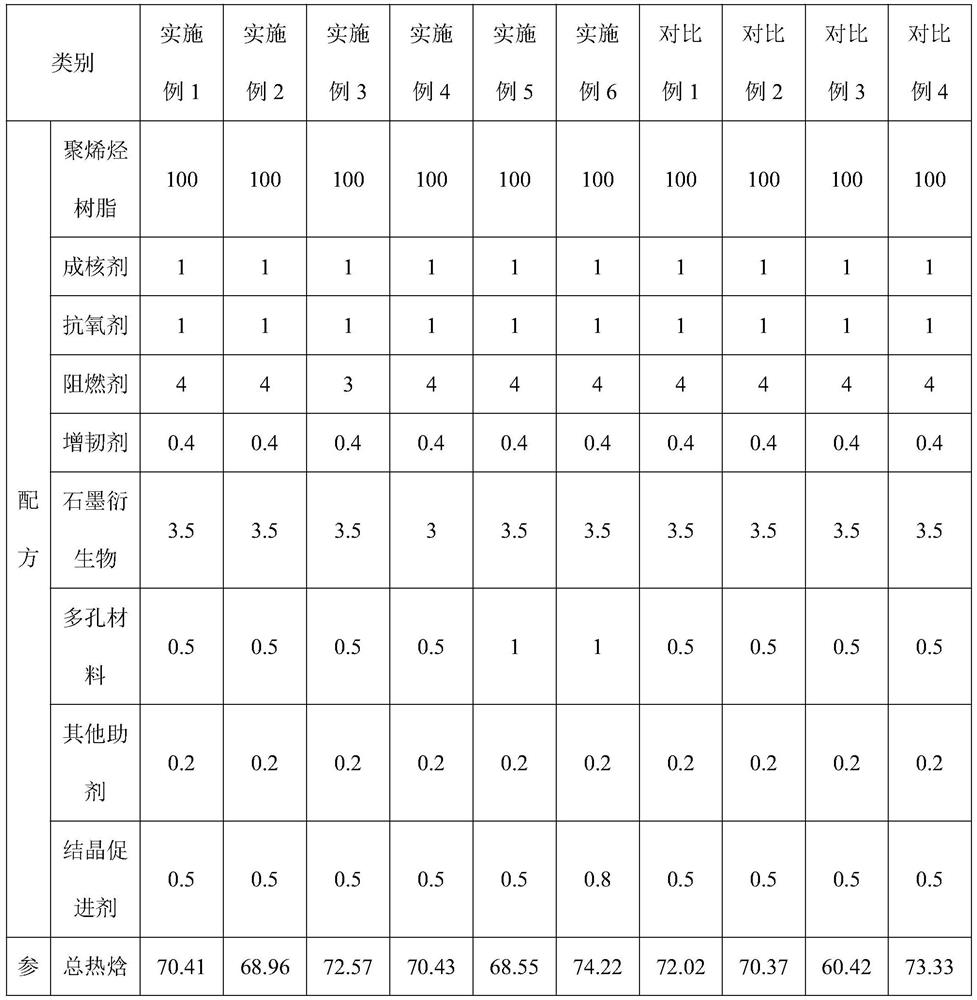

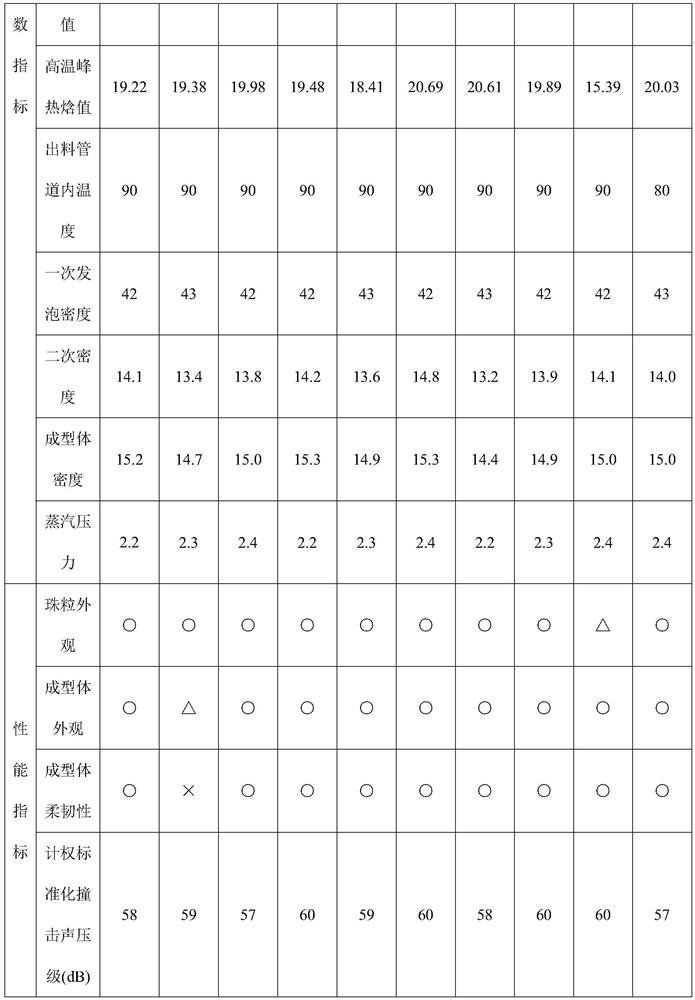

[0036] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] The preparation method of expanded polyolefin beads comprises the steps:

[0038]Step 1: Add polyolefin resin and additives into a high-speed mixer, stir and mix evenly, and pass through a screw extruder with a temperature of 200-240°C in the mixing zone to obtain evenly mixed polyolefin resin particles;

[0039] Wherein, the additives include nucleating agents, antioxidants, flame retardants, toughening agents, graphite derivatives, porous materials, crystallization accelerators and other additives.

[0040] Specifically, the nucleating agent is kaolin, talc or zinc borate;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com