High-speed tabletting system for pharmaceutical equipment and control method of high-speed tabletting system

A technology for pharmaceutical equipment and tablets, which is used in material forming presses, presses, manufacturing tools, etc., can solve problems such as difficulty in tablet quality control, and achieve the effect of improving the efficiency of finished products and reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

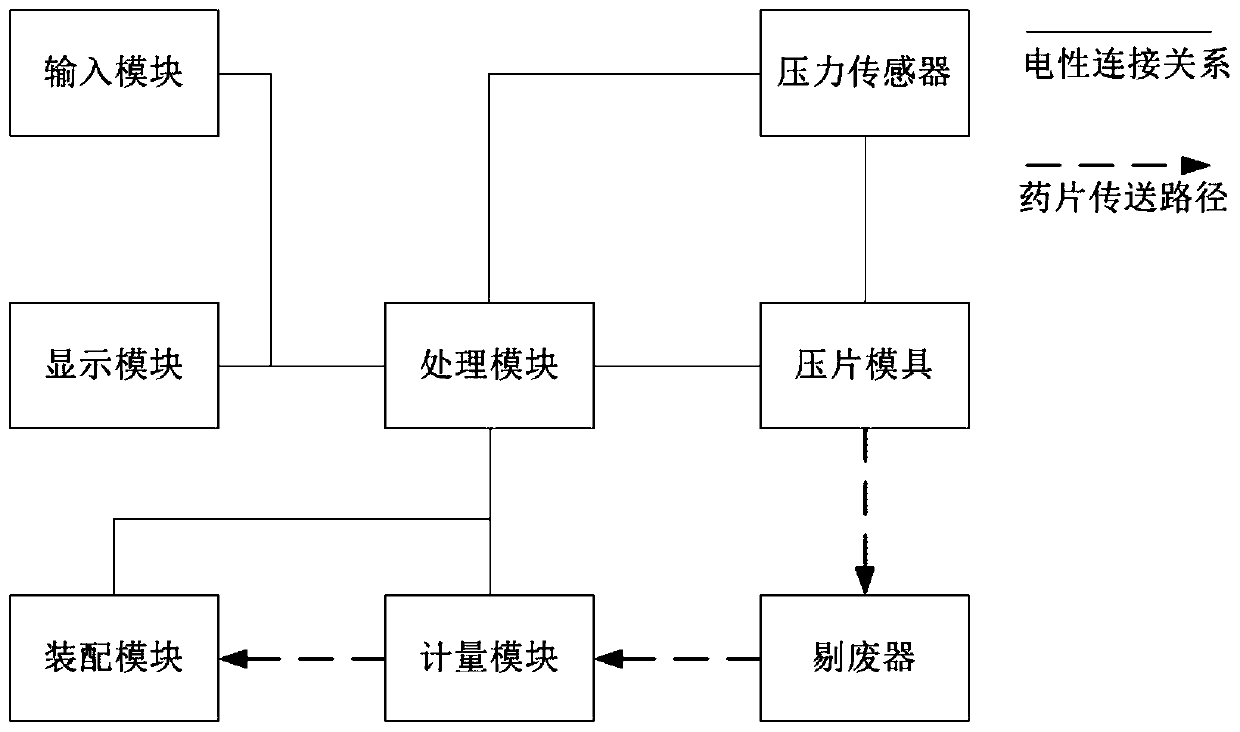

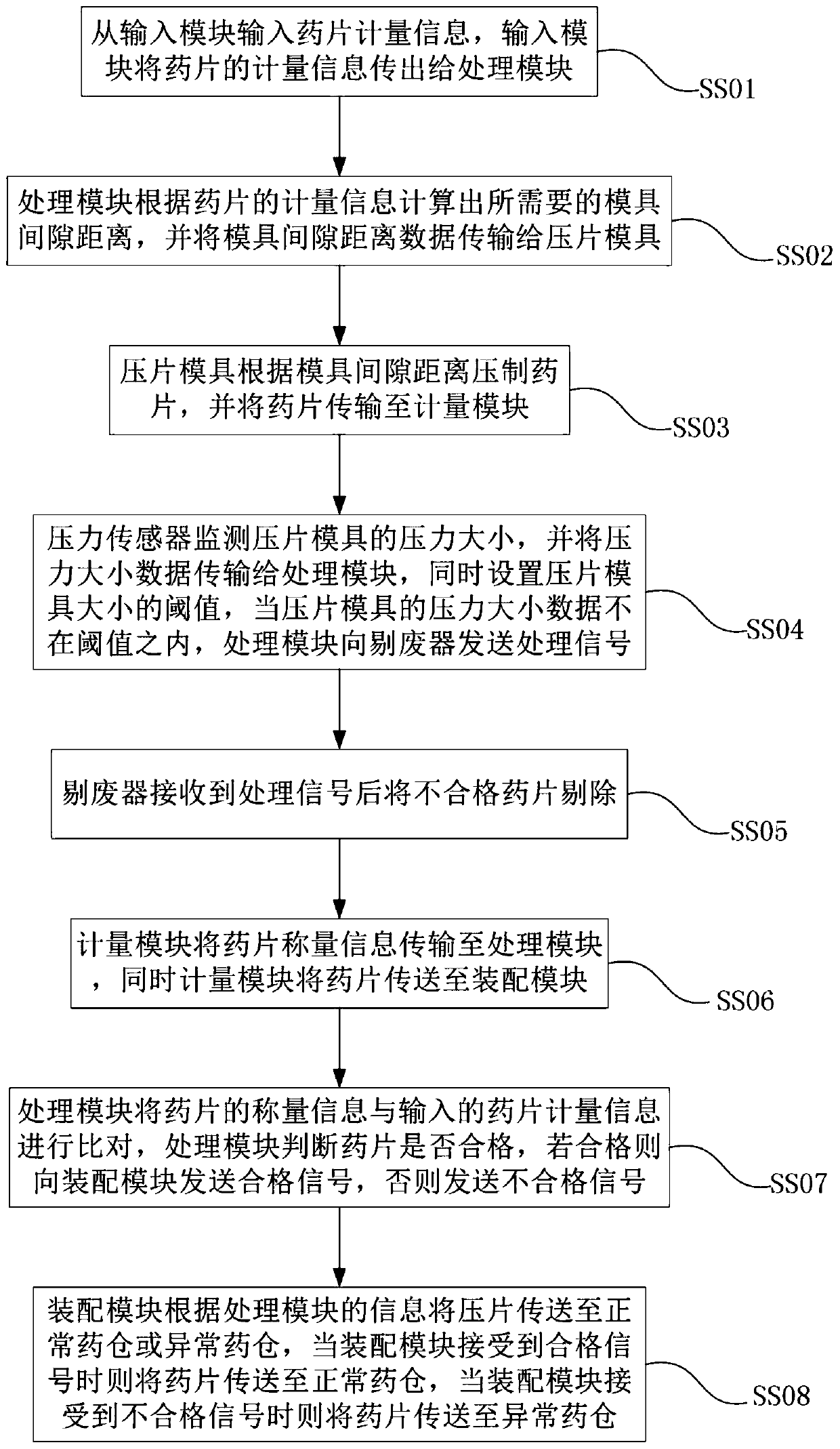

[0033] see figure 1 As shown, the present invention is a high-speed tablet pressing system for pharmaceutical equipment, including a processing module, a display module, an input module, a tablet pressing mold, a metering module, a pressure sensor, a rejecter and an assembly module, and the processing module and the input module are electrically connection, the input module sends tablet metering information to the processing module; the processing module is electrically connected to the tableting die, and the processing module sends the die gap distance information to the tableting die; the pressure sensor is electrically connected to the processing module, and the pressure sensor monitors the tableting die. Pressure value, and transmit the pressure value to the processing module; the waste ejector is connected with the tablet pressing mold, and the tablet pressing mold transmits the formed medicine to the waste ejector, the height solenoid valve is electrically connected with ...

Embodiment 2

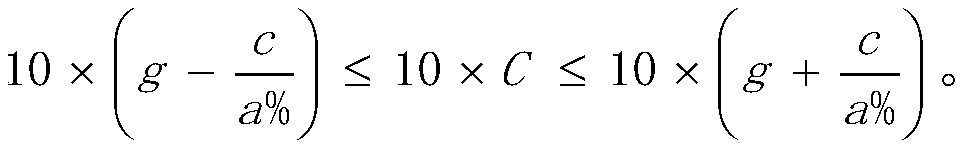

[0054] see Figure 1-2 As shown, the present invention is a high-speed tablet pressing system and its control method for pharmaceutical equipment. Its working principle is: in the process of mixing medicines into tablets, since the ingredients of the medicine have been proportioned according to the formula, in order to determine the dosage of the medicine , it is necessary to calculate the weight of the tablet. The processing module monitors the pressure of the tableting mold through the pressure sensor, and conducts a preliminary screening of unqualified tablets according to the pressure threshold. Then the processing module determines the weight of the tablet through the data input by the input module, and then The dose module and the assembly module re-inspect the tablets, pass the remaining qualified tablets, and retain the unqualified drugs for reprocessing or treatment to improve the accuracy of the drug composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com