Multi-hole automatic threading and winding thread-bound file binding machine

A technology of automatic winding and automatic threading, applied in the direction of binding, etc., can solve the problems of low binding efficiency, prone to drop or disconnection, and slow drilling efficiency and threading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

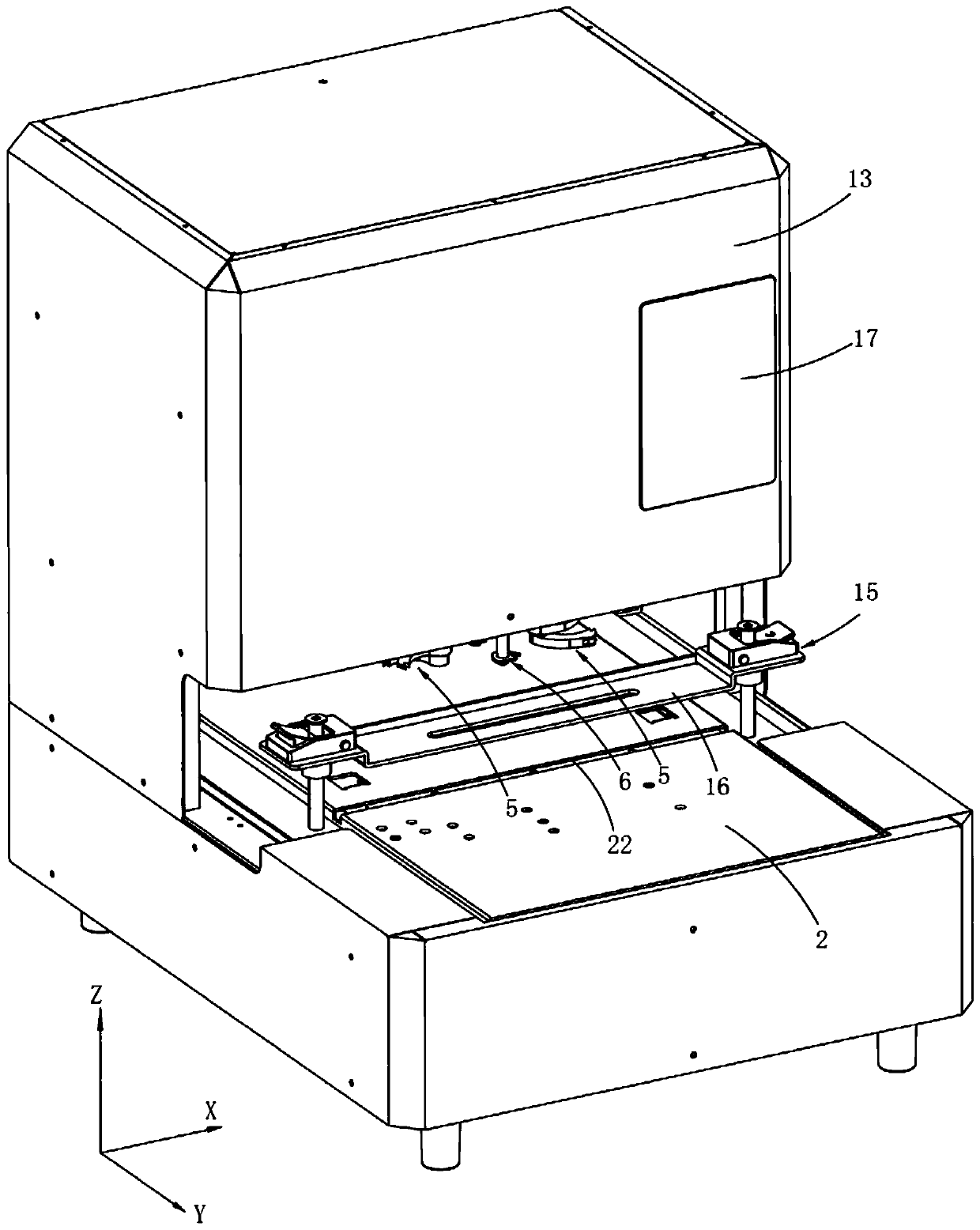

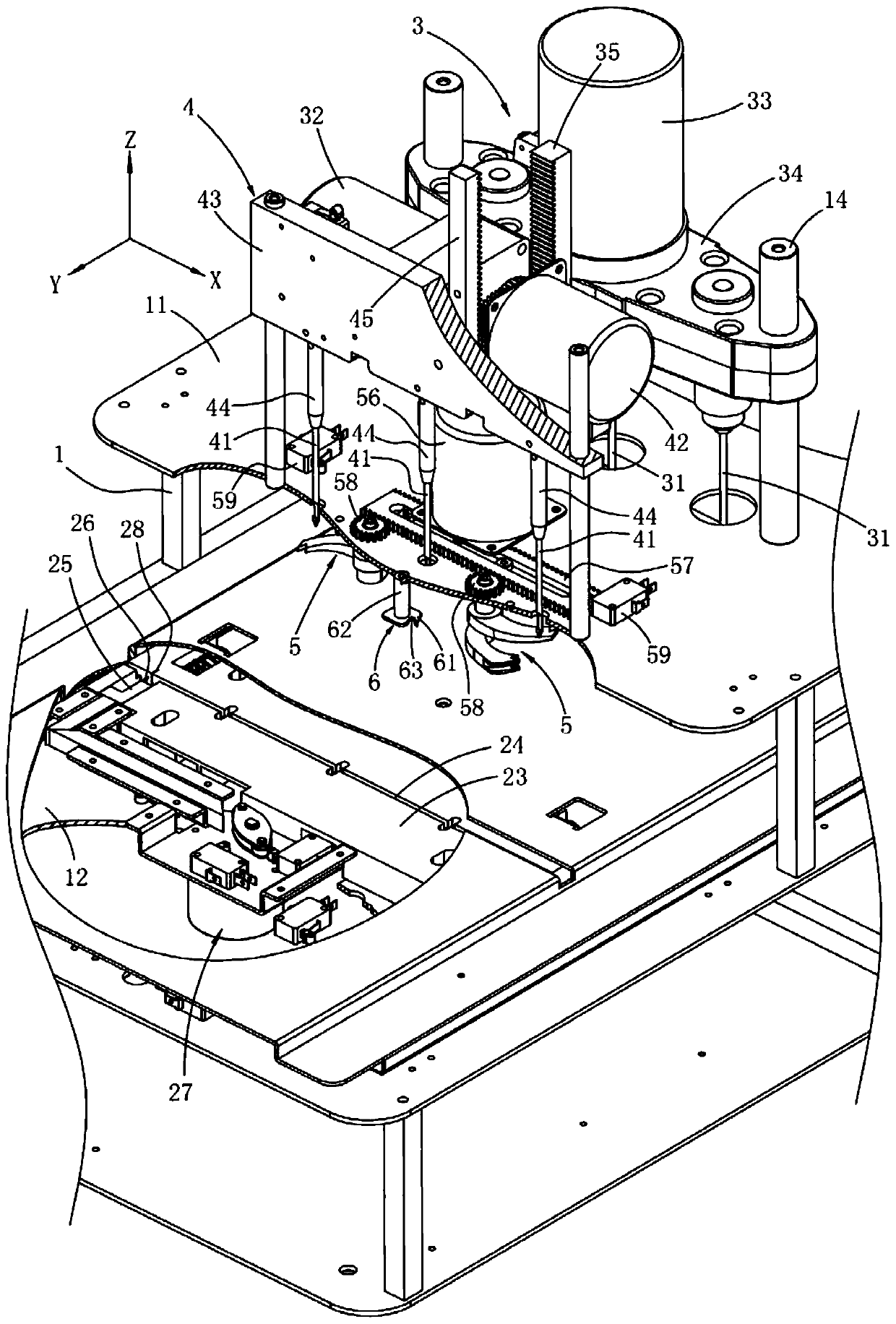

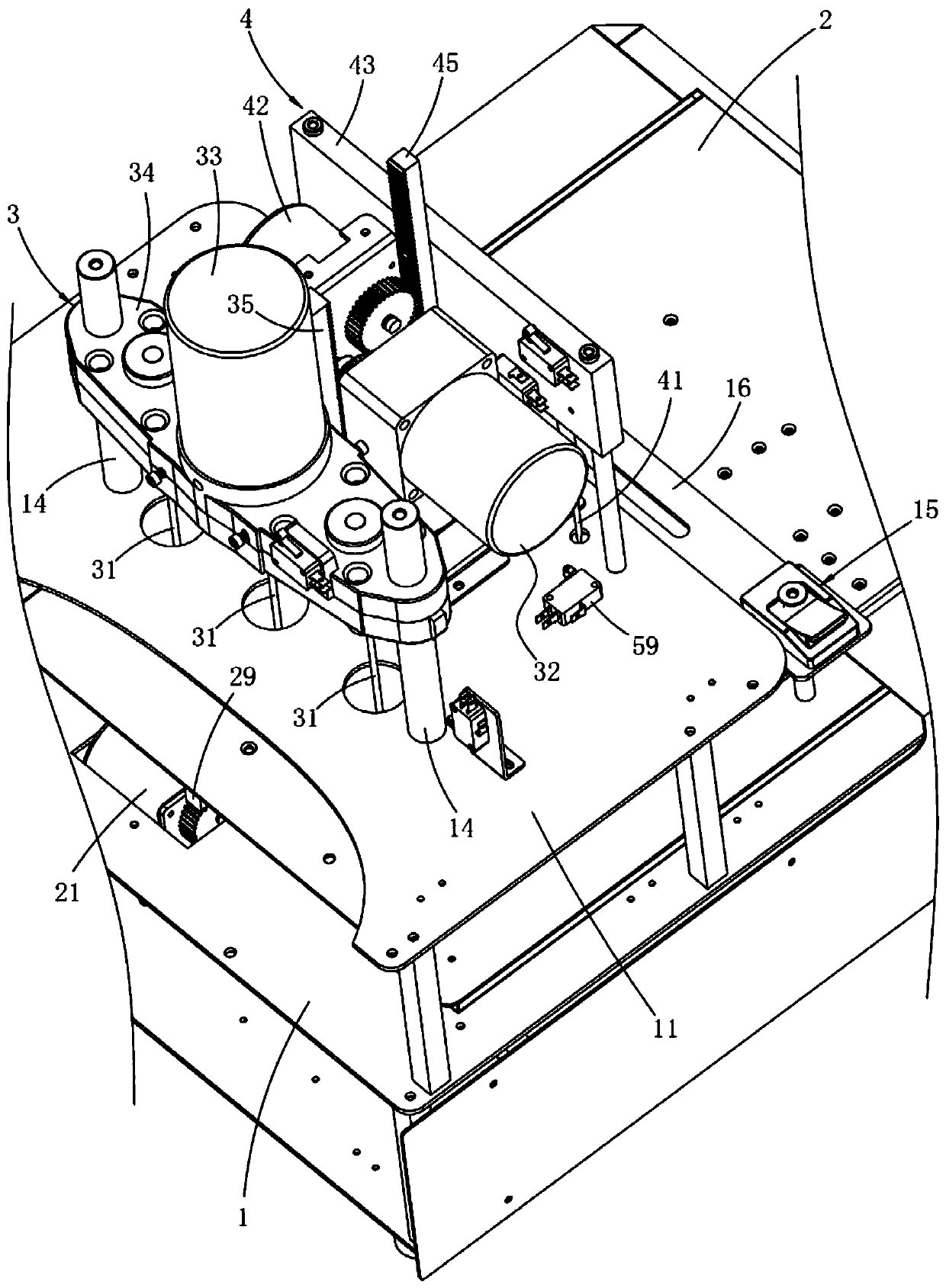

[0093] A wire-loaded file binding machine with multi-hole automatic threading and winding, Figures 1 to 6 As shown, it includes a frame 1, a control circuit, and a file binding platform 2 arranged in the middle of the frame 1 for fixing and binding documents. A drilling device 3 is provided above or below the file binding platform 2. The drilling device 3 At least one drill 31 is provided for drilling holes in the binding documents and forming a binding threading hole in the binding documents. A wire feeding device 4 is provided above or below the file binding platform 2. The wire feeding device 4 is provided with at least two wire feeding devices. The thread needle 41 is used to pull the binding thread through the binding threading hole to form a group of binding line segments folded in half. The document binding platform 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap