Batch boxing system for gun heads of pipetting guns

A technology of pipetting gun and tip box, applied in packaging and other directions, can solve problems such as large time and manpower, and achieve the effect of reducing experimental cost, facilitating promotion, and saving boxed tips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

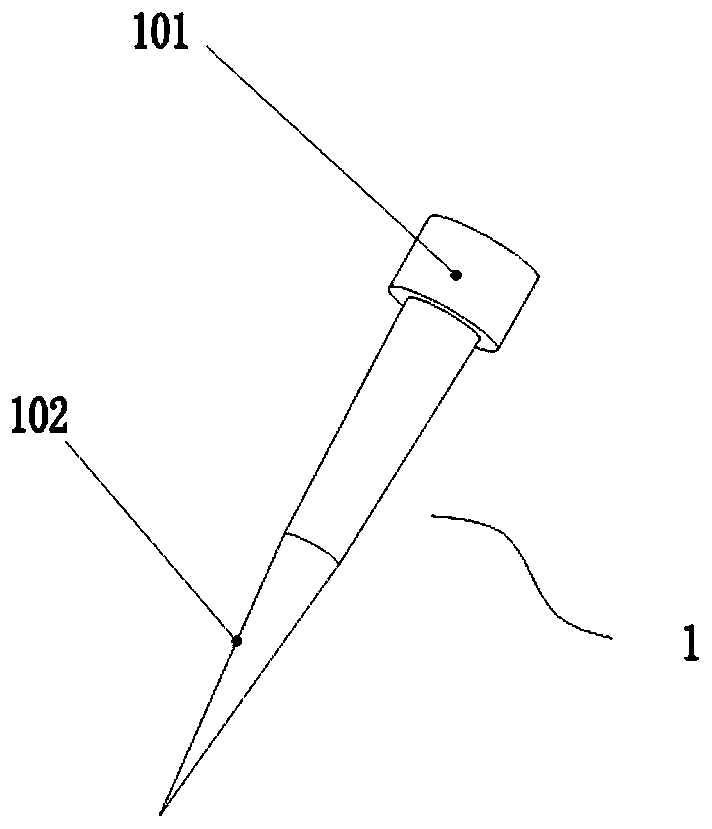

[0040] Such as figure 1 The tip 1 of the shown pipette gun has a small end 102 at its front end and a large end 101 at its rear end. The small end 102 is used to insert into the container to introduce the solution, and the large end 101 is used to match the output of the pipette gun. port installation connection. When loaded into the gun tip box 3, the small end 102 faces down and the big end 101 faces up.

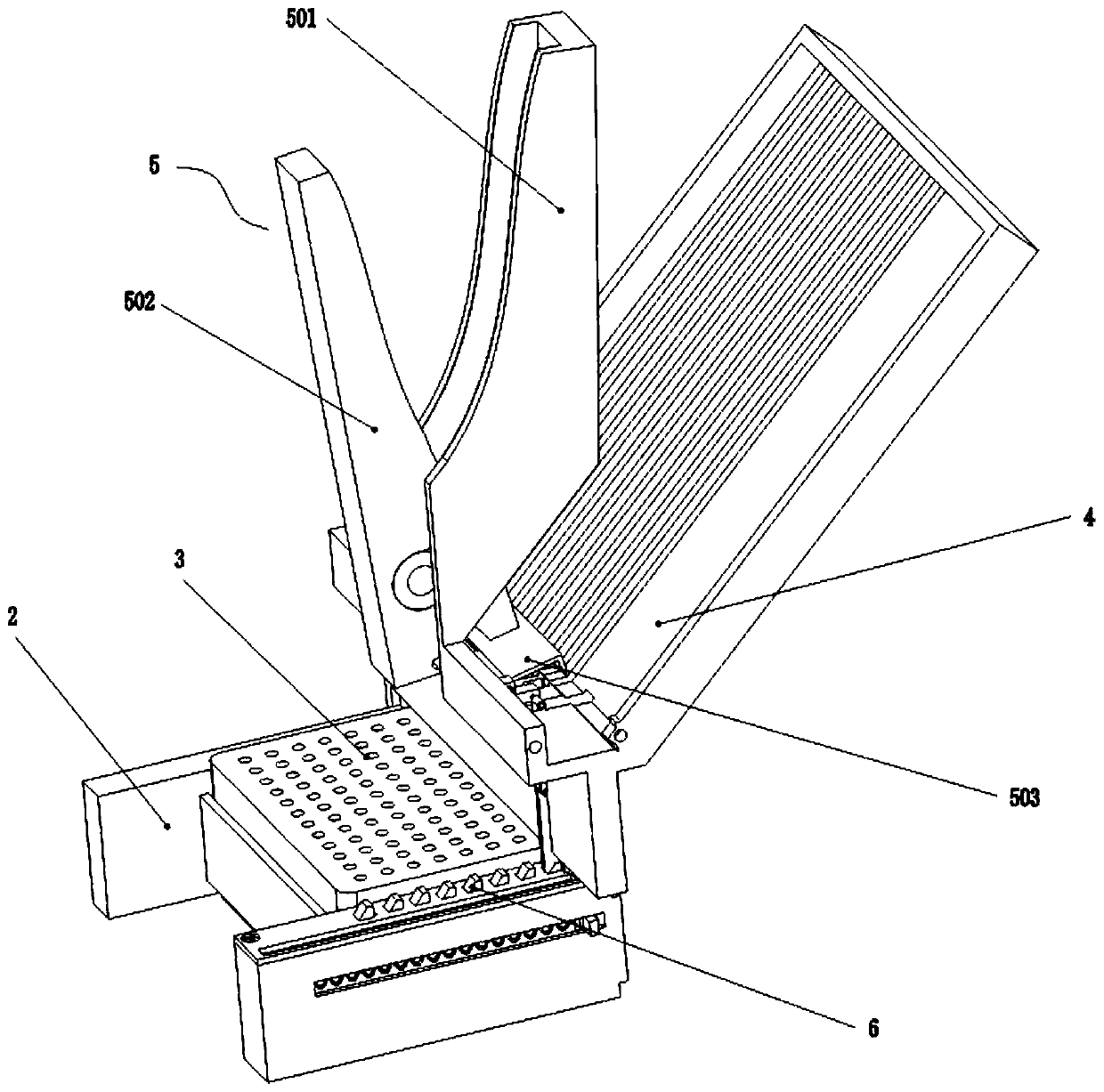

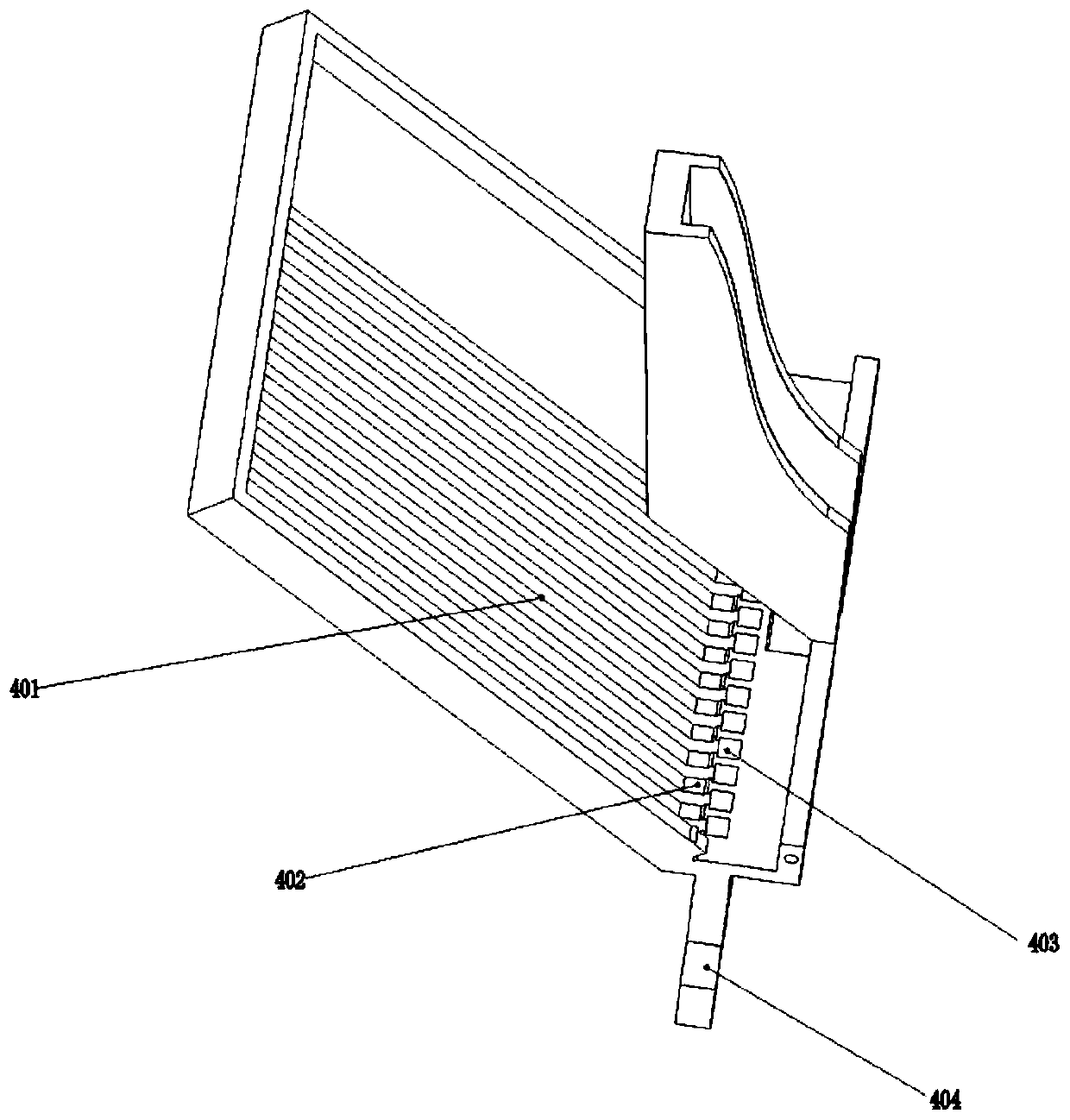

[0041] Such as figure 2 , 3 , a pipette gun tip 1 batch packing system shown in 4, which includes: a base 2 for placing the tip box 3; Arrange it into an orderly arranged slot 401 and a blanking channel 403 for the aforementioned ordered gun tips 1 to fall into the gun tip box 3; a loading device 5 is used to push the orderly arranged gun tips 1 to return to The slot 401 is moved to the blanking channel 403; the loading device 5 and the sieve tray 4 can move relative to the base 2 as a whole, so that the blanking channel 403 corresponds to the tip 1 hole on the tip bo...

Embodiment 2

[0052] Such as Figure 8 , 9 , 10, the basic structure of this embodiment is basically the same as Embodiment 1, the difference is mainly in the structure of the loading device 5, and the loading device 5 in this embodiment includes a trigger 508, a connecting rod assembly, a scraper 503 and a guide structure, the trigger 508 connects the scraper 503 through a connecting rod structure and drives it to move upward, and the guide structure includes a guide slant block 506 that guides the scraper 503 to move upward from the initial position while away from the blanking channel 403 , the horizontal passage for guiding the scraper 503 to move toward the direction close to the discharge passage 403 after passing over the top position of the first guide part, and the vertical passage for guiding the scraper 503 to move downward to the initial position. The inclined guide block 506 has an inclined guide surface that gradually inclines away from the blanking channel 403 from bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com