Precast concrete slab connection box device capable of limiting self-locking and unlocking and reinforcement connection

A technology of prefabricated concrete slabs and connection boxes, which is applied to floors, building components, walls, etc., can solve the problems of mortar aging, insufficient sleeve grouting, and many assembly supports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

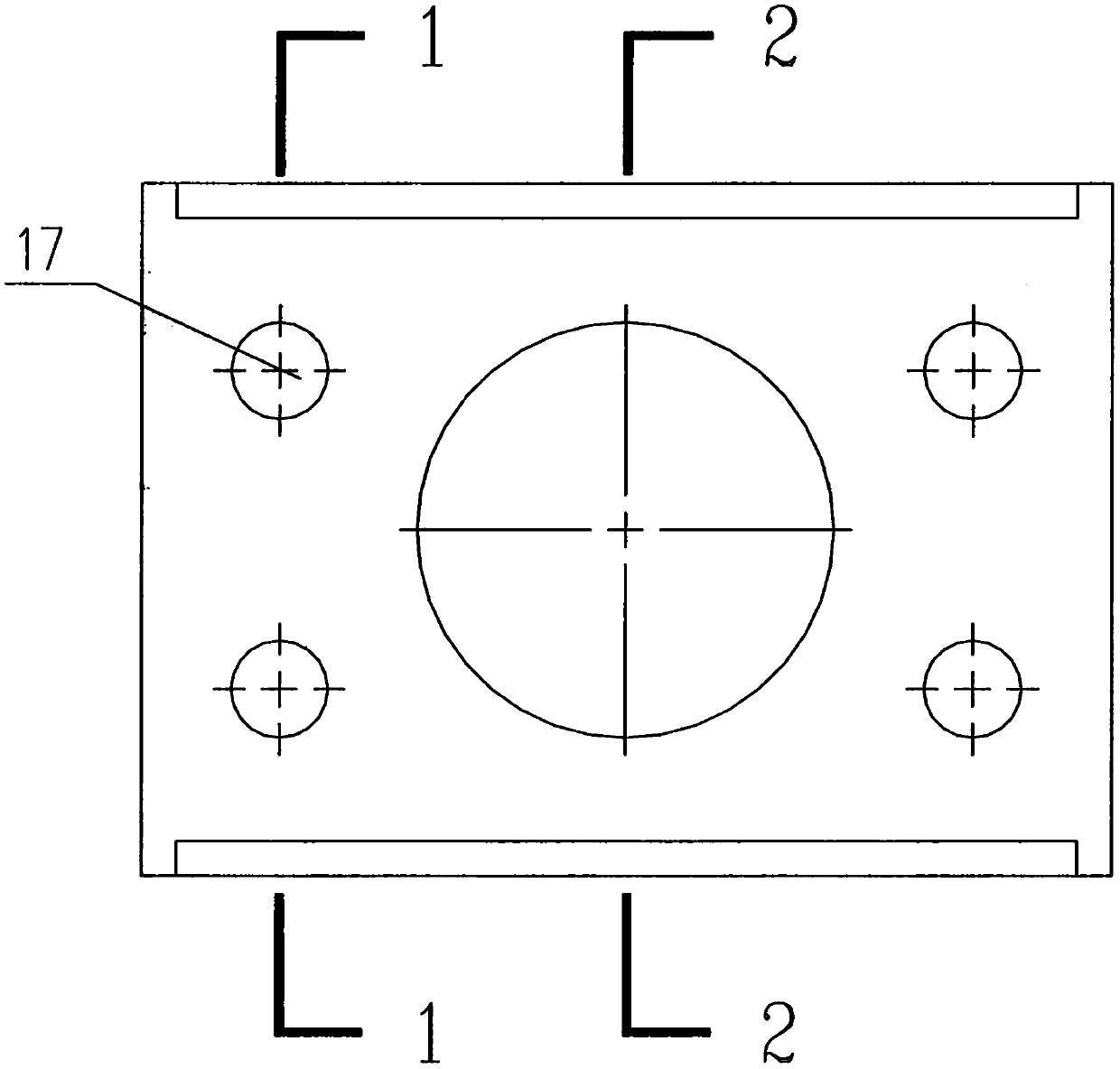

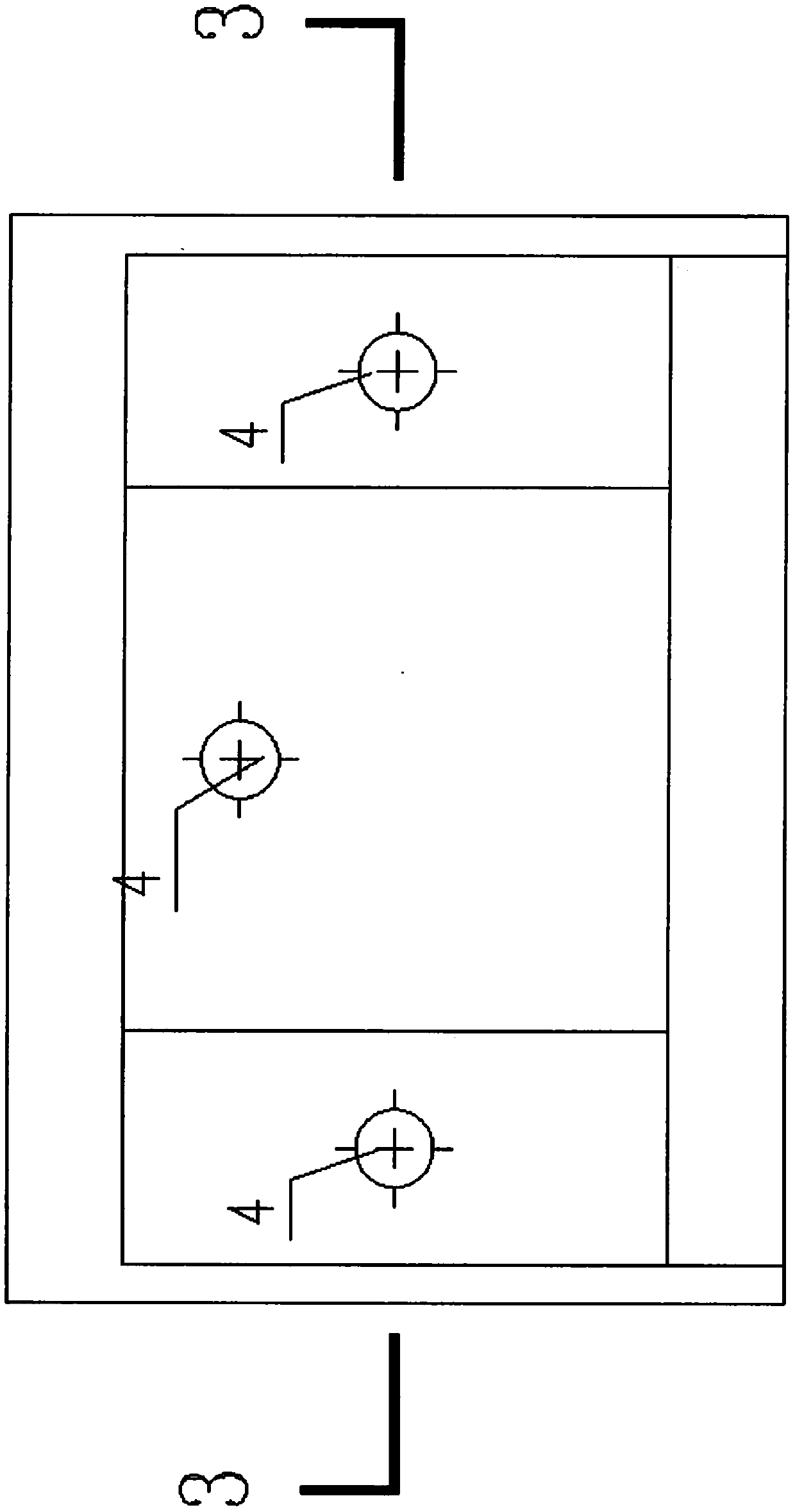

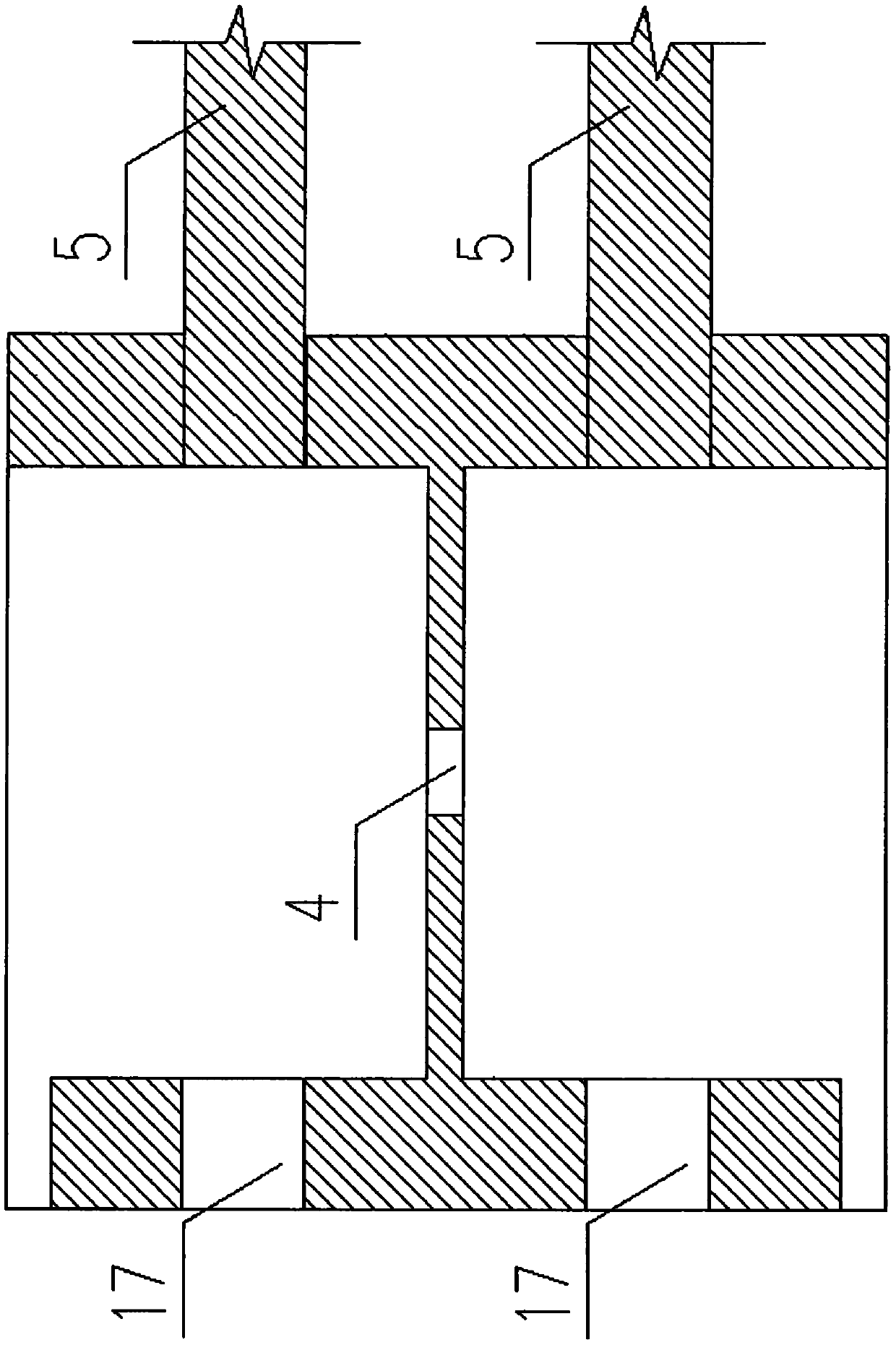

[0043] according to Figure 1-18 As shown, the present invention includes: A connection box 1, B connection box 2, steel bar connection area 3, grouting hole 4, plate steel bar 5, steel ball 6, pipe body with bolt 7, steel ball cap 8, spring 9, rack 10 , gear rod 11, pull rope hole 12, tapered grooved pipe body with hole 13, transmission force member 14, prefabricated plate 15, pull rope 16, bolt hole 17, tether ring 18, right circular pipe body 19, groove 20, left round pipe body 21, small left round pipe body 22, perforate 23, lock piece 24, small opening 25, opening 26, grooving 27, movable plate 28.

[0044] The prefabricated concrete slab connection box device with limit self-locking, unlocking and steel bar connection includes: B connection box 2 fixedly connected to the right side of the prefabricated slab 15, A connection box 1 fixedly connected to the left side of the prefabricated slab 15; The box 2 is movably connected with the A connection box 1 through a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com