Mining dust removal fan

A dust removal fan and mine-used technology, which is applied in mine/tunnel ventilation, dust prevention, mining equipment, etc., can solve problems such as mine safety hazards, high noise, and the inability of dry dust collectors to filter toxic and harmful components, so as to reduce management Effects of Difficulty and Danger Factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

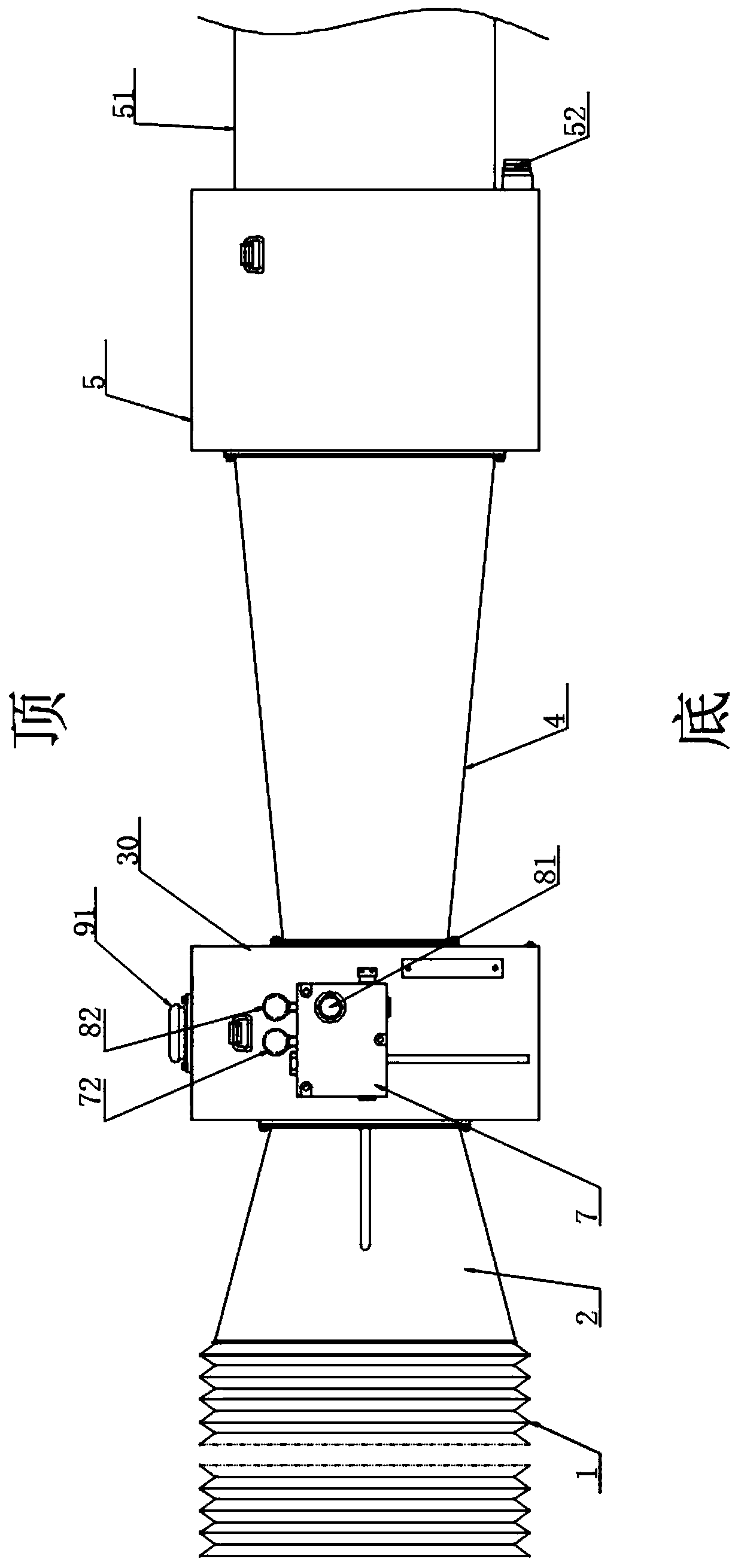

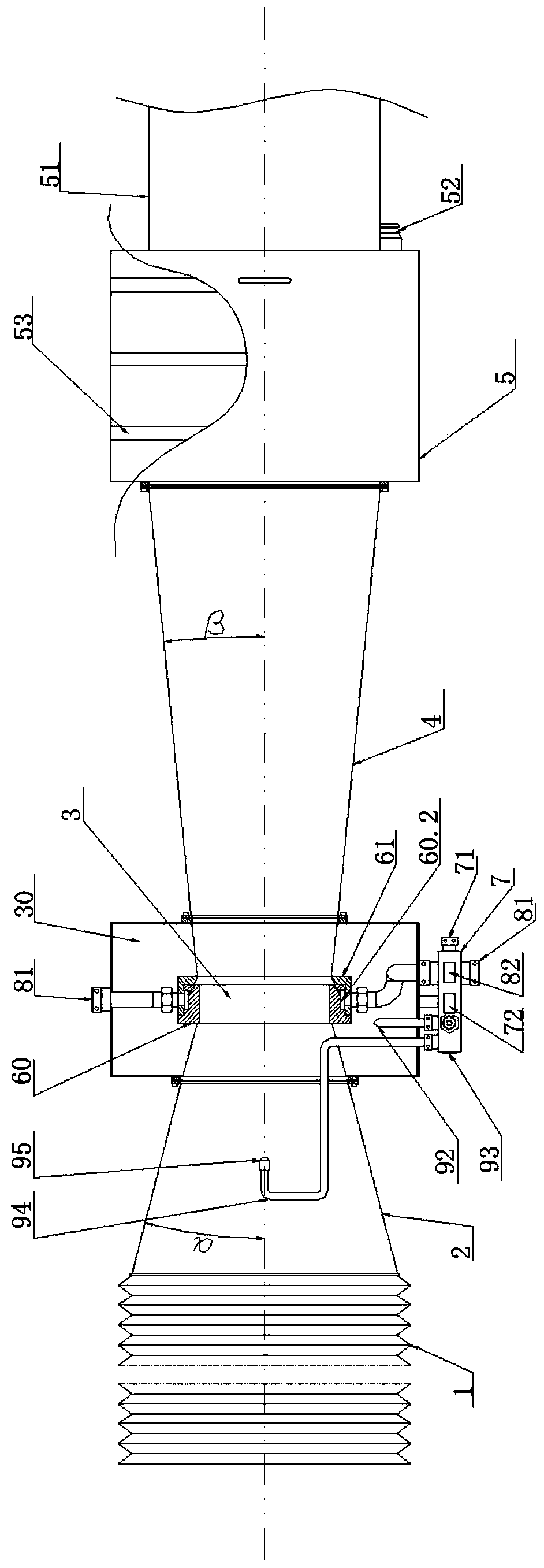

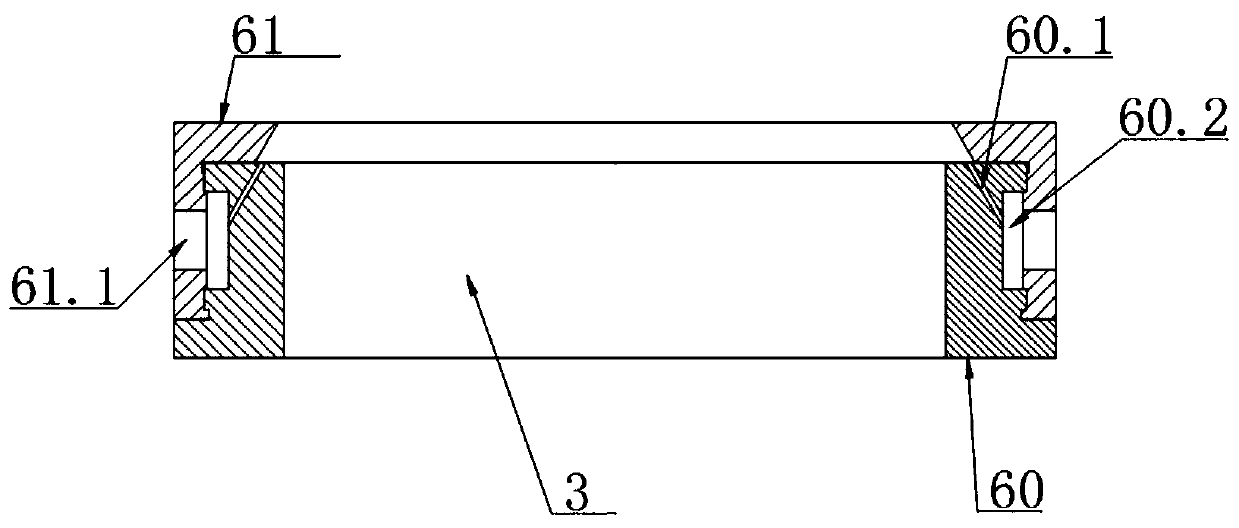

[0038] as attached Figures 1 to 7 , a mining dust removal fan, comprising: a suction section 2 and an amplifying section 4 constituting a Venturi tube structure. The included angle β between the side of the section 4 and the central axis ranges from 5 degrees to 7 degrees; a drainage chamber 3 is also provided between the suction section 2 and the amplification section 4, and the drainage chamber 3 includes: a circular amplifier penetrating at both ends The assembly I60, and the amplifier assembly II61 arranged on the outer contour of the amplifier assembly I60, the drainage chamber 3 is arranged at the center of the amplifier assembly I60. The amplifier assembly I60 includes: several annular exhaust holes 60.1 and exchange chambers 60.2 evenly distributed on the amplifier assembly I60; one end of the exhaust eye 60.1 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com