Corrosion rate measurement using sacrificial probe

A corrosion rate and probe technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as difficult to measure local corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

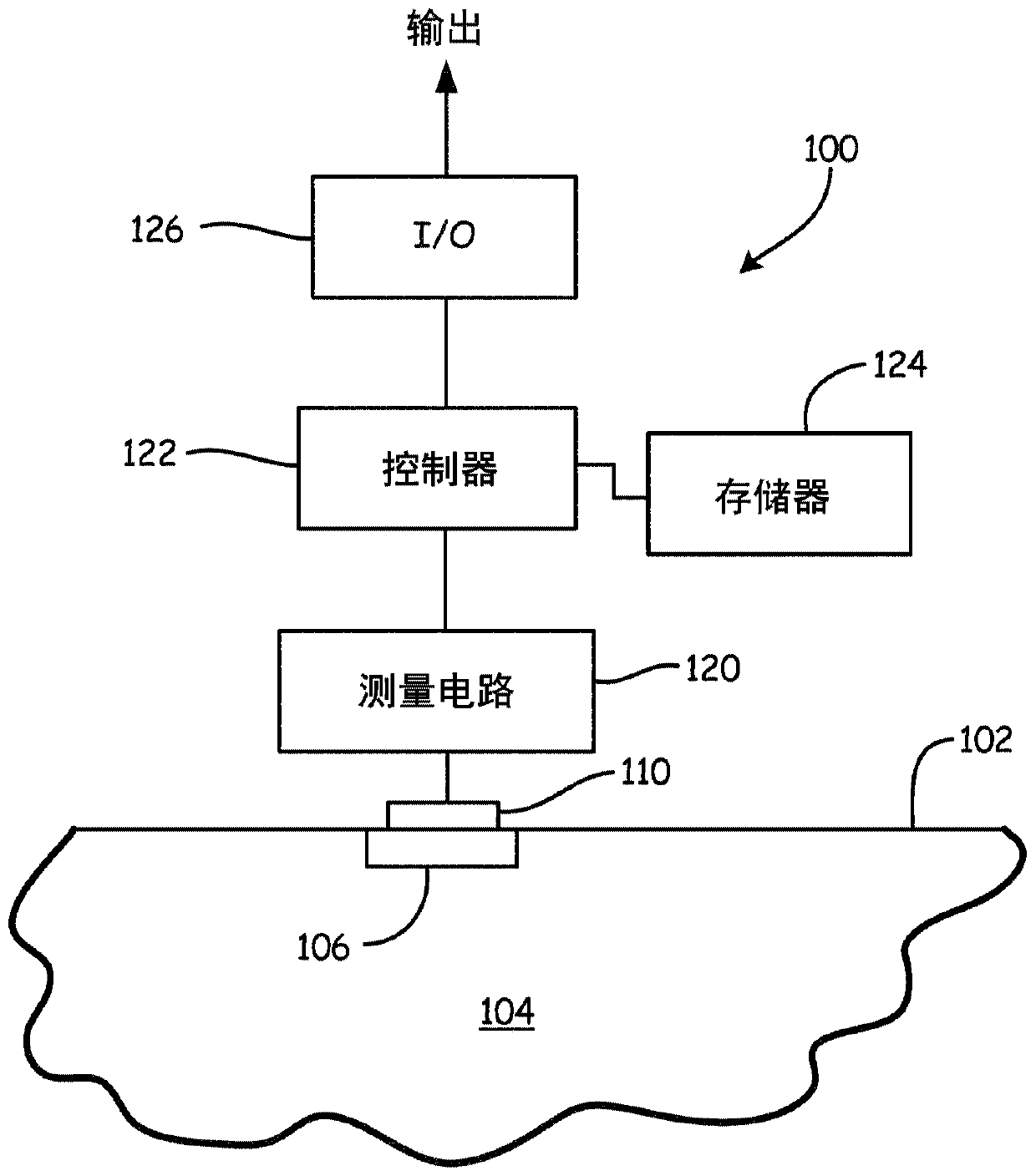

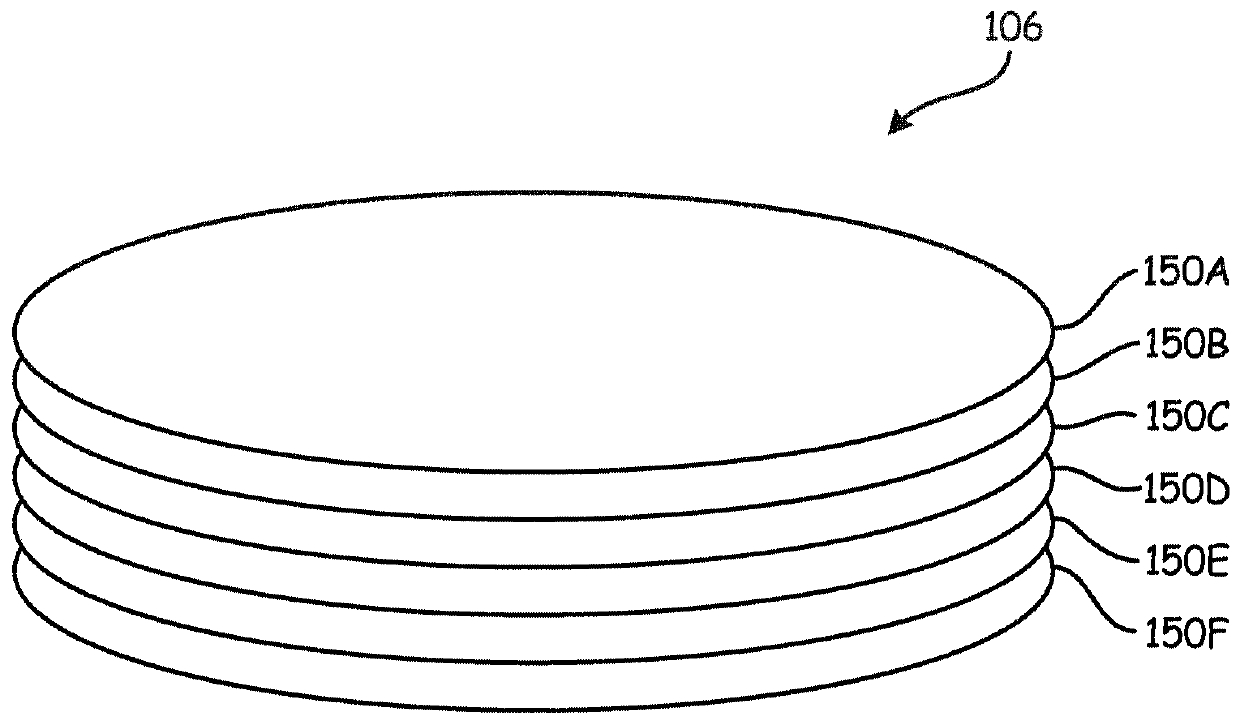

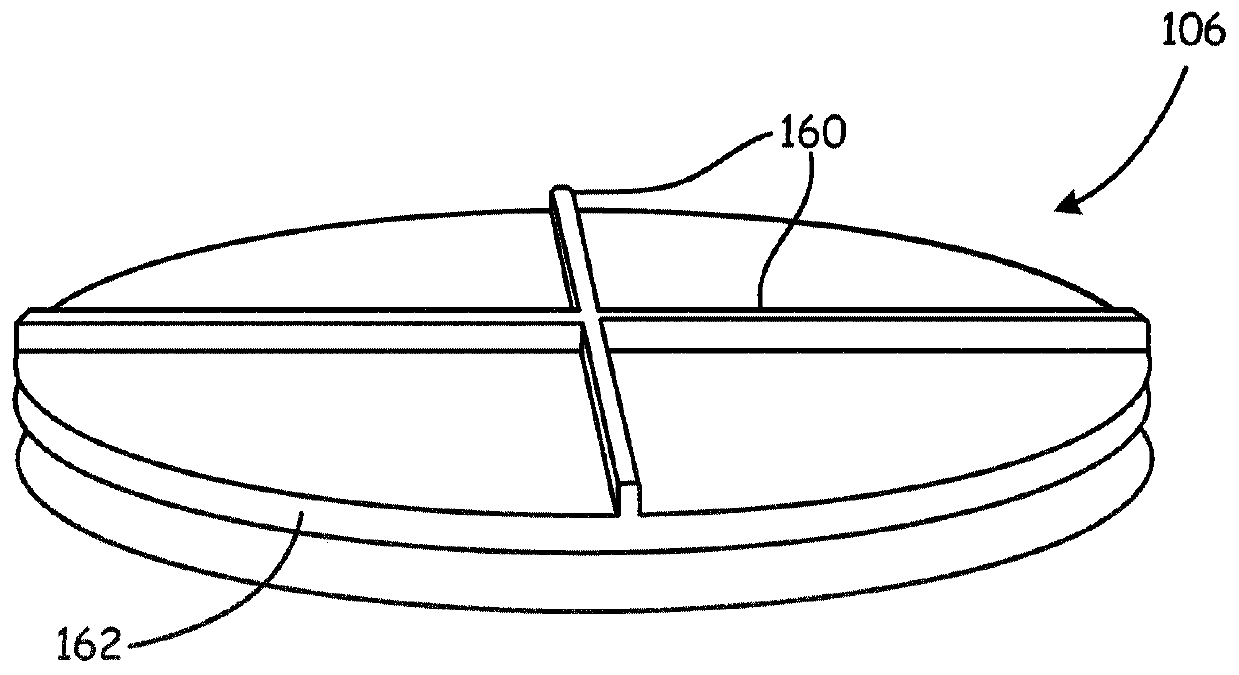

[0013] A corrosion rate measurement system is provided in which a sacrificial probe is configured to corrode at different rates over time when exposed to a corrosive fluid. For example, the probes may be configured to corrode initially at a relatively fast rate to provide higher sensitivity to corrosion measurements. However, after prolonged use, the probe may be configured to corrode at a different rate, for example at a slower rate. This allows the probe to continue to operate and provide limited functionality without requiring immediate replacement. Configurations may also be provided that increase the probe's susceptibility to specific types of corrosion, such as pitting type corrosion.

[0014] Various intrusive and non-intrusive methods are used to monitor corrosion including material loss, electrochemical measurements and analytical measurements. Various techniques include measuring resistance, eddy current, conductivity, ultrasound and acoustics. The most common tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com