Workpiece quality detection mark recording system

A technology for detecting marks and recording systems, applied in computer parts, image data processing, instruments, etc., can solve the problems of scrapped workpieces, find scrapped workpieces, etc., reduce manual operations, have a high degree of automation, and facilitate production The effect of line loopholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

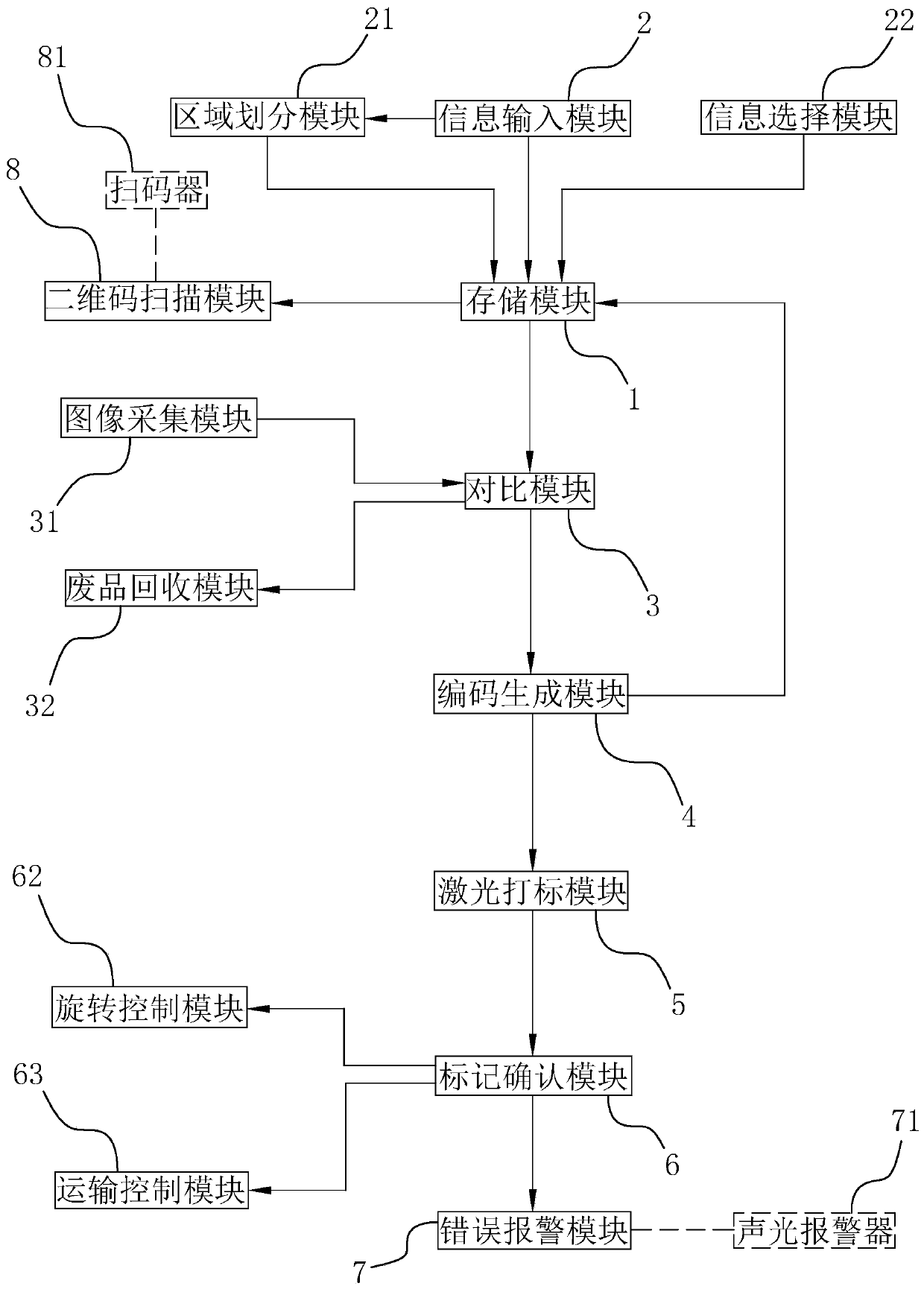

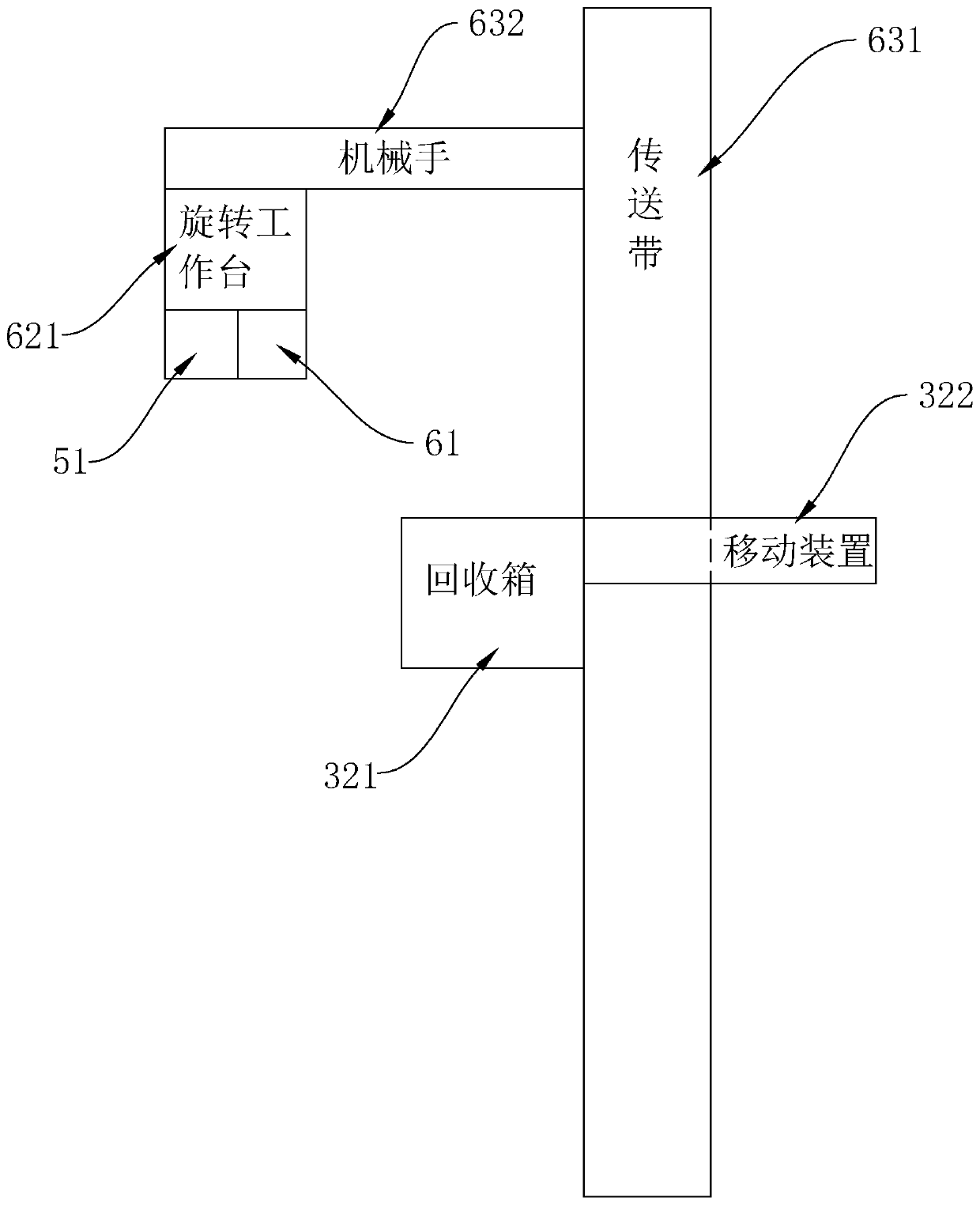

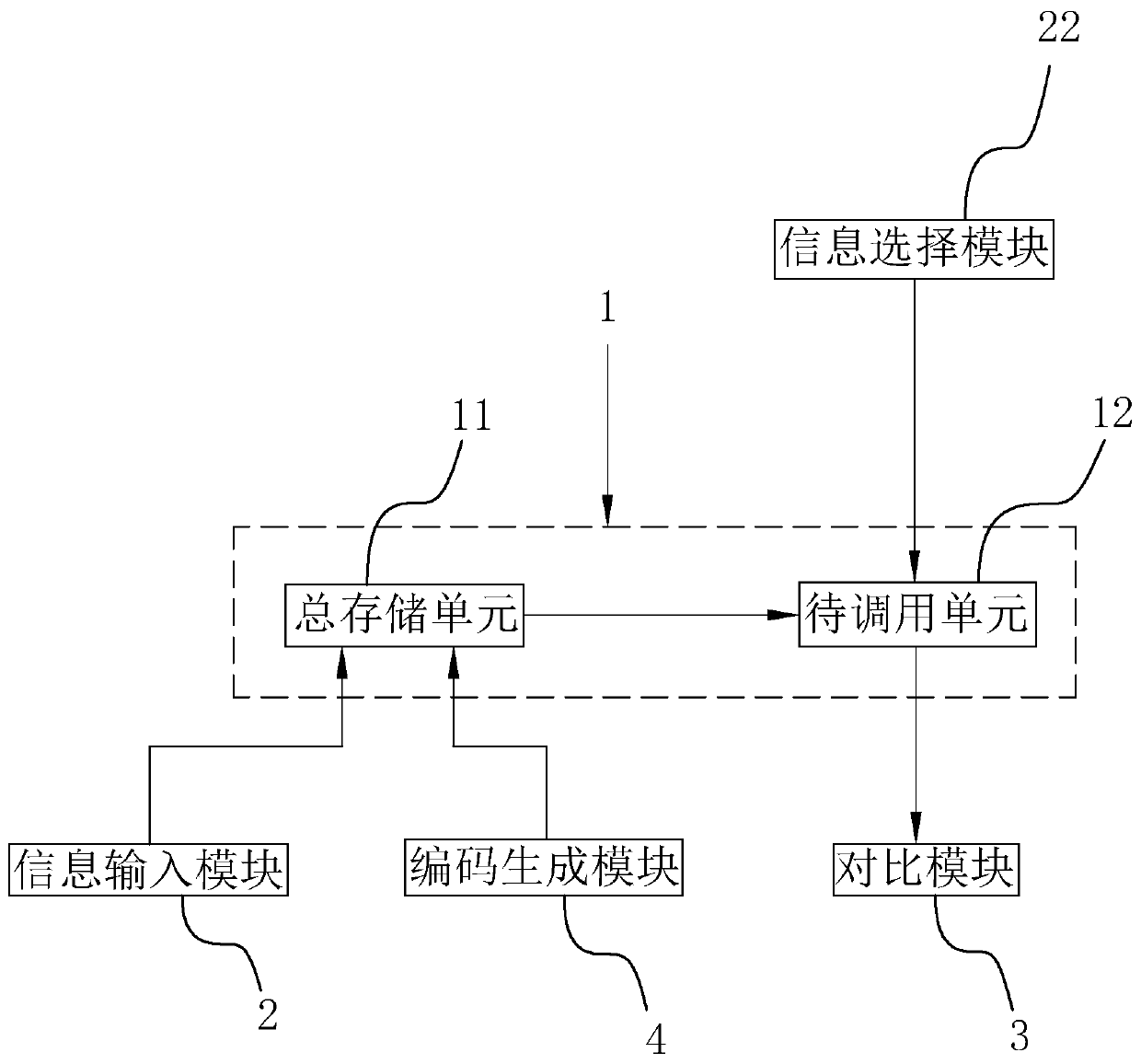

[0043] Embodiment: a kind of workpiece quality detection mark recording system, such as figure 1 As shown, it includes a storage module 1, an information input module 2, an area division module 21, an information selection module 22, a comparison module 3, an image acquisition module 31, a waste recycling module 32, a code generation module 4, a laser marking module 5, and a mark confirmation Module 6, rotation control module 62, transport control module 63, error alarm module 7 and two-dimensional code scanning module 8.

[0044] Such as figure 1 As shown, the information input module 2 receives information such as comparison information input from the outside and transmits it to the storage module 1 for storage. The area division module 21 receives the comparison information input by the information input module 2, and the area division module 21 divides the comparison information into a plurality of processing units, and transmits the processing units to the storage module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com