Cleaning device for gear machining

A technology for cleaning devices and gears, applied in liquid cleaning methods, dry gas layout, lighting and heating equipment, etc., can solve the problems of poor contact of gears, uneven dispersion, and influence on carbon content on the surface, so as to avoid the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

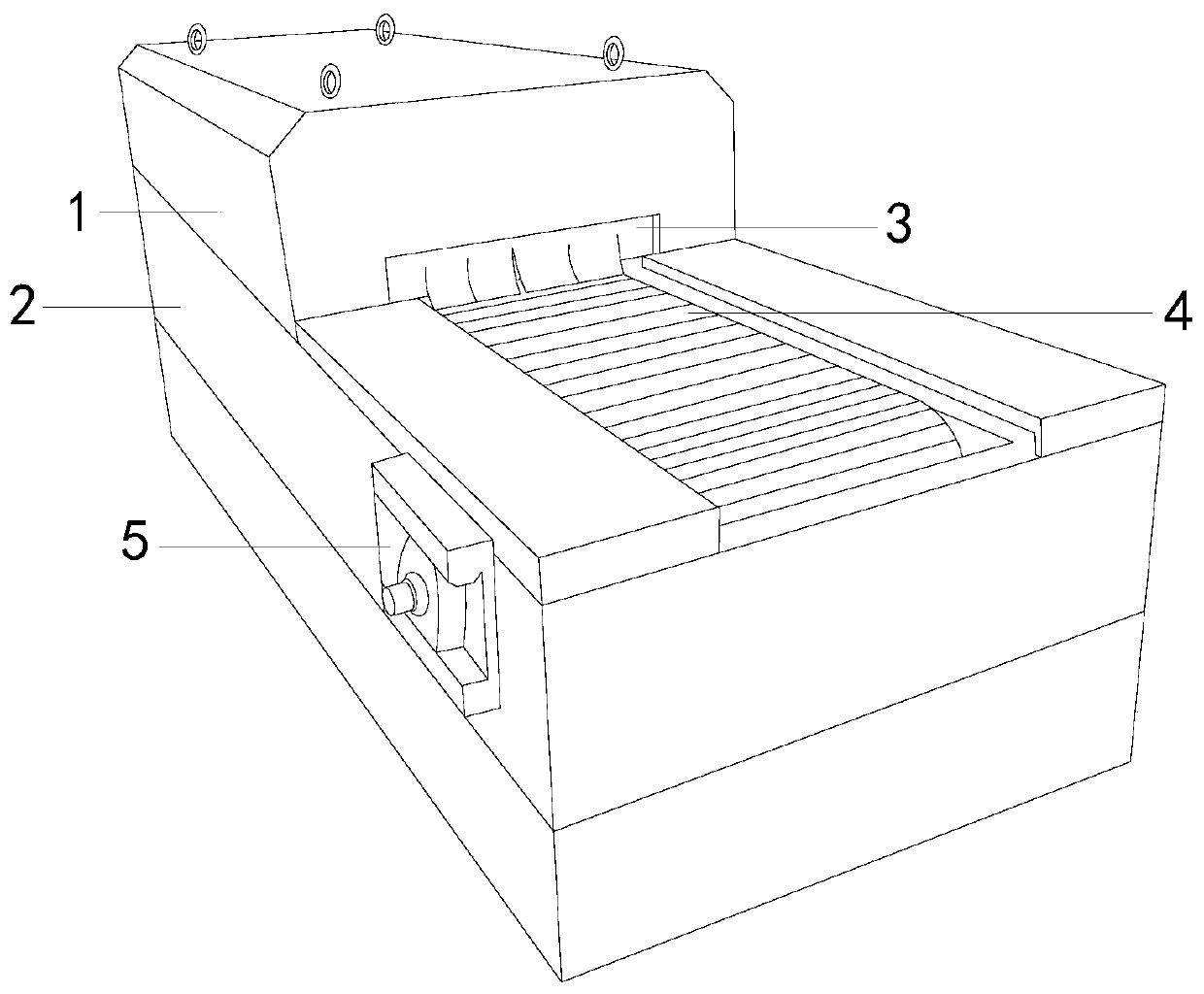

[0020] see figure 1 , the present invention provides a cleaning device for gear processing. Its structure includes: a cleaning mechanism 1, a base 2, a dustproof plate 3, a water absorption mechanism 4, and a driver 5. The cleaning mechanism 1 is connected to the water absorption mechanism 4 and is equipped with On the base 2, the side plate of the base 2 is provided with a driver 5, and the dustproof plate 3 is arranged on the upper part of the middle of the connection between the cleaning mechanism 1 and the water absorption mechanism 4 on the base 2. When the driver 5 is powered on, the internal power mechanism will Drive the cleaning mechanism 1 and the water absorption mechanism 4 to run.

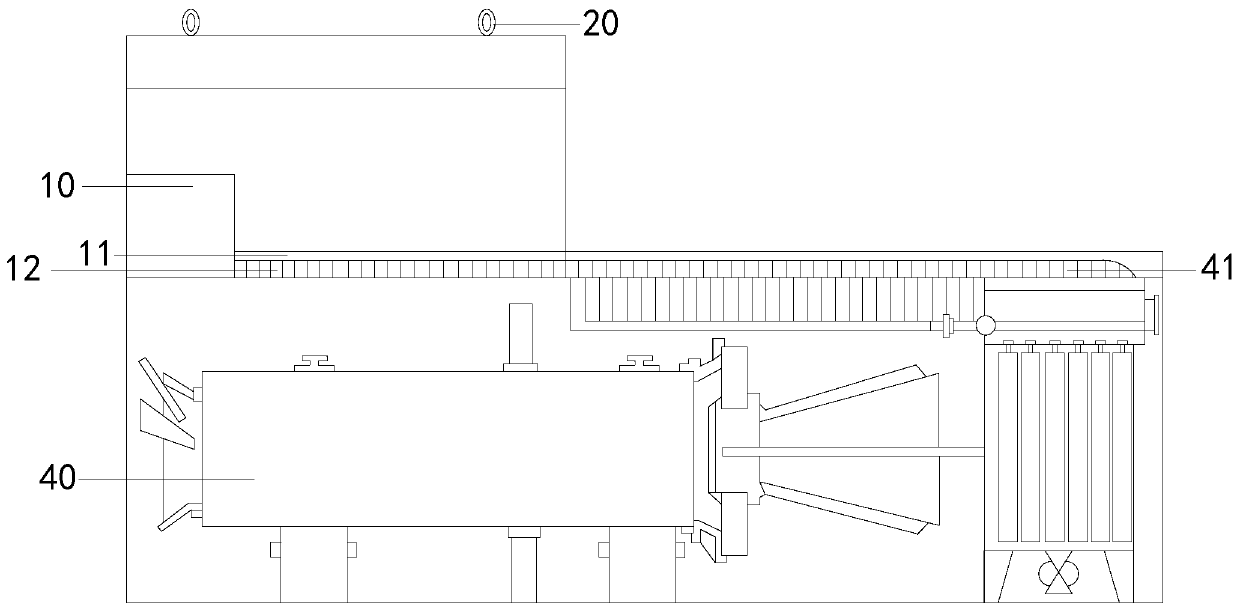

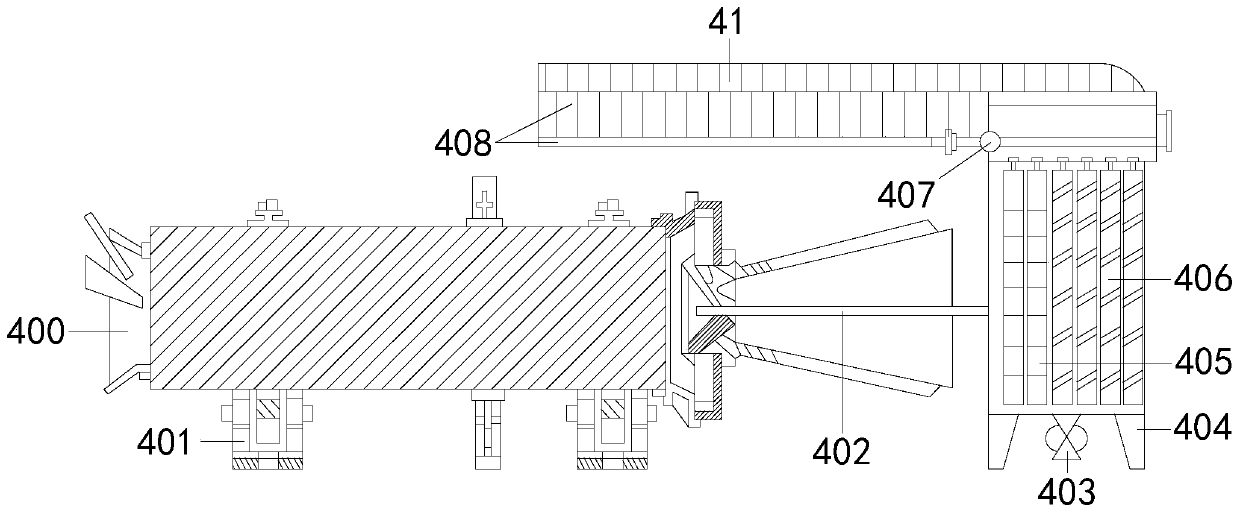

[0021] see figure 2 , Figure 5 , the present invention provides a cleaning device for gear processing, its structure includes: the cleaning mechanism 1 is composed of a water tank 10, a spray pipe 11, and a transmission shaft 12, the water tank 10 is connected to the spray pipe 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com