Multi-head type stamping method

A multi-head, to-be-stamped technology, applied in the field of sheet metal stamping and forming, can solve the problems that the driving device cannot be effectively used, the efficiency cannot be improved, the shaping effect is poor, and the like, and the shaping effect is good and improved. Energy saving, rounded shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

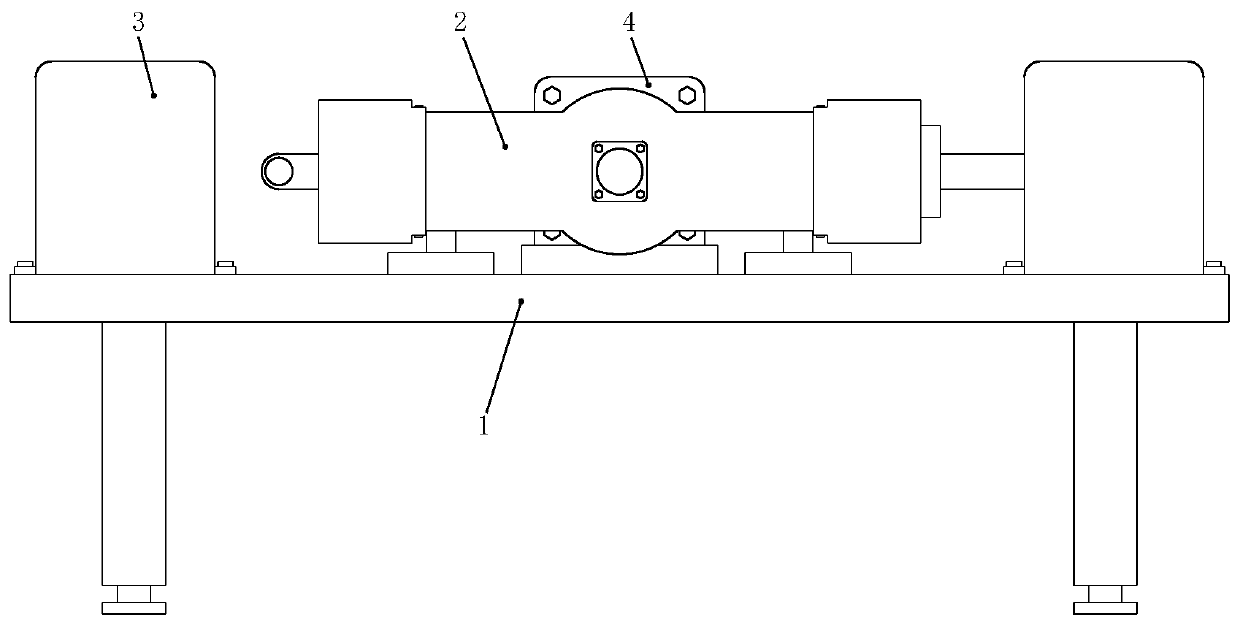

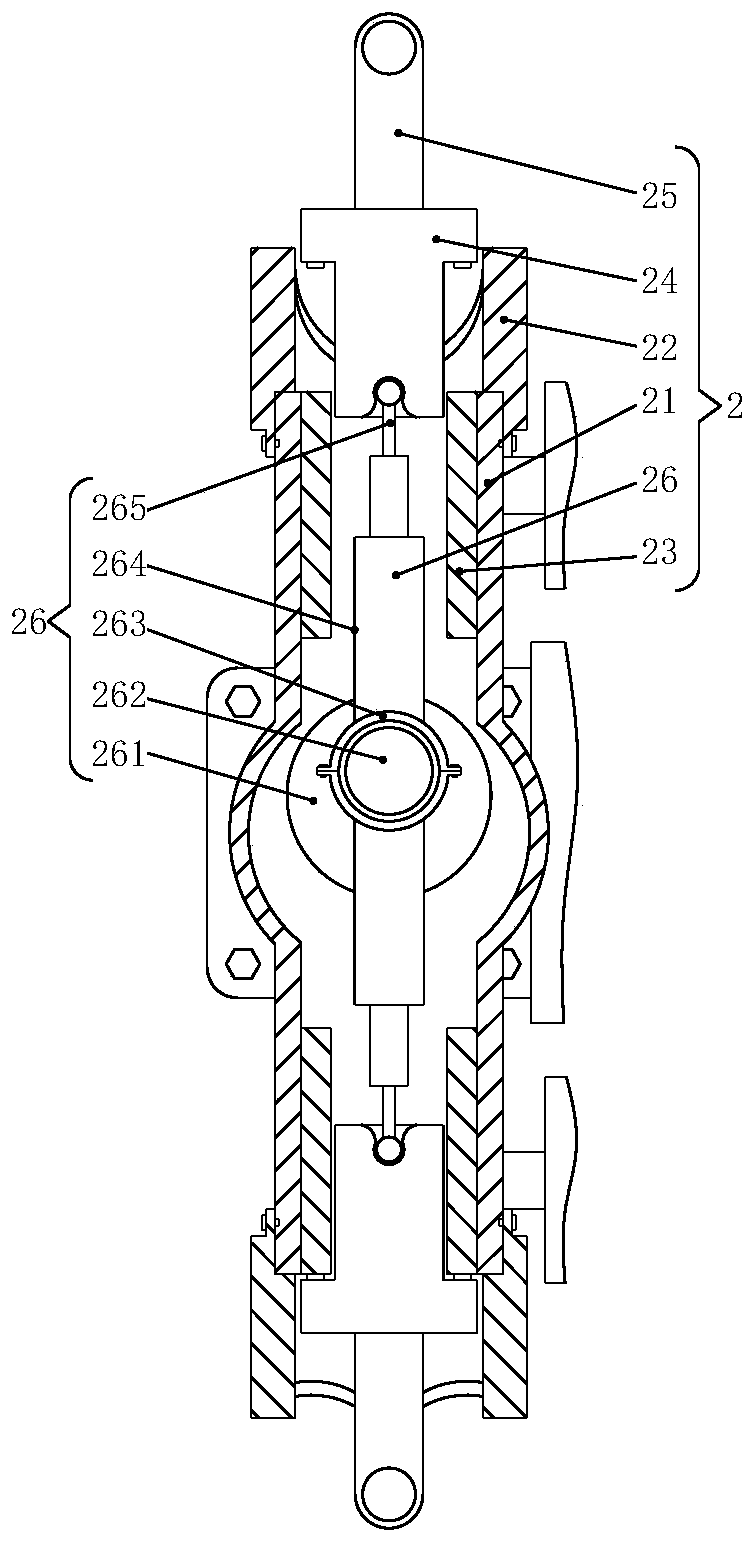

[0029] Referring to 1-6, a multi-head punching method, the multi-head punching method specifically includes the following steps:

[0030] S1. Device inspection: Use a torque wrench to test the torque of the bolts at the connection of the device in sequence, and compare the qualified parameter table. If it is weak and unqualified, use a torque wrench to tighten the bolts to the acceptable torque range;

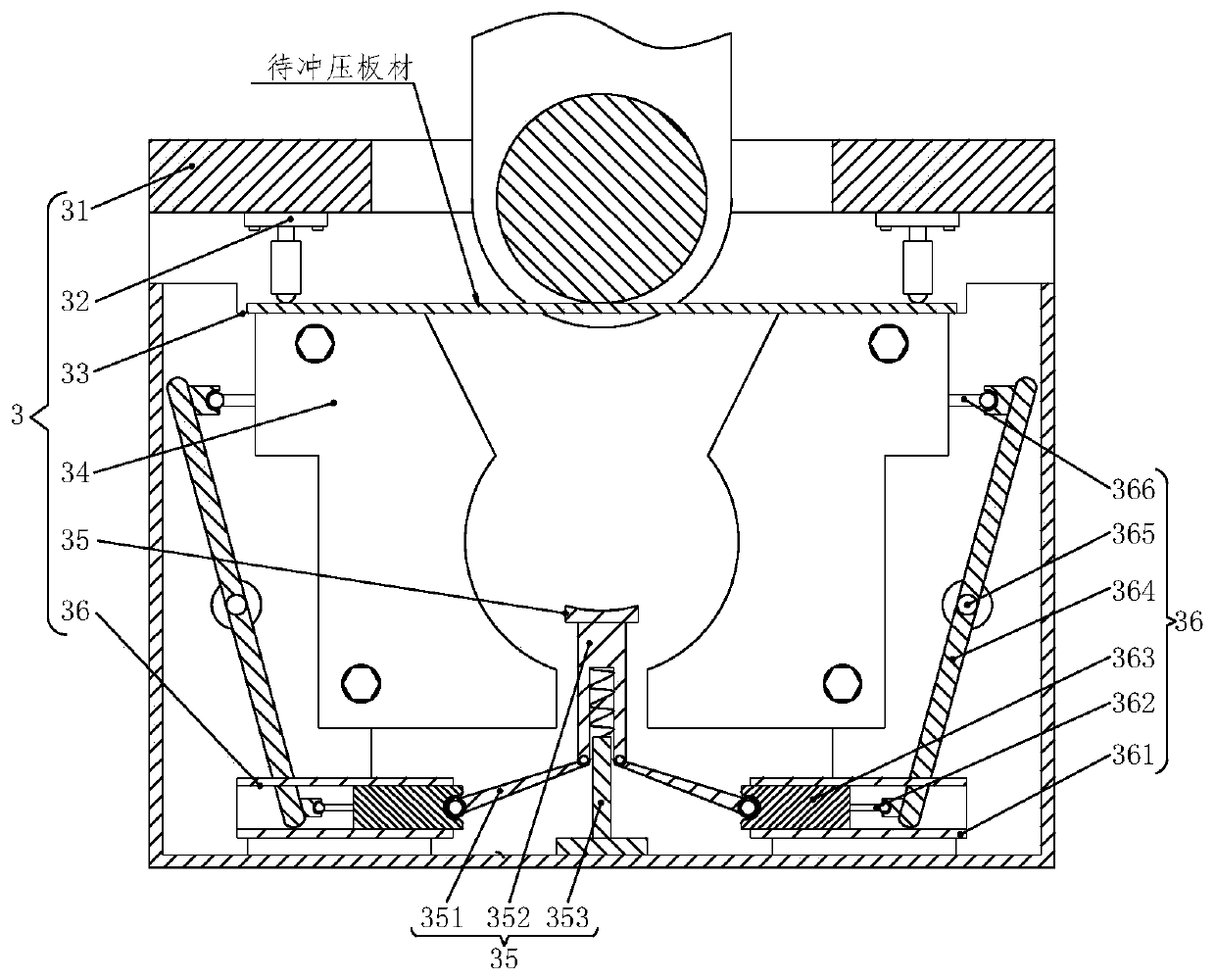

[0031] S2. Unloading: insert the plate to be punched into the upper end of the placement slot, and make the clamping assembly 32 cling to the upper surface wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com