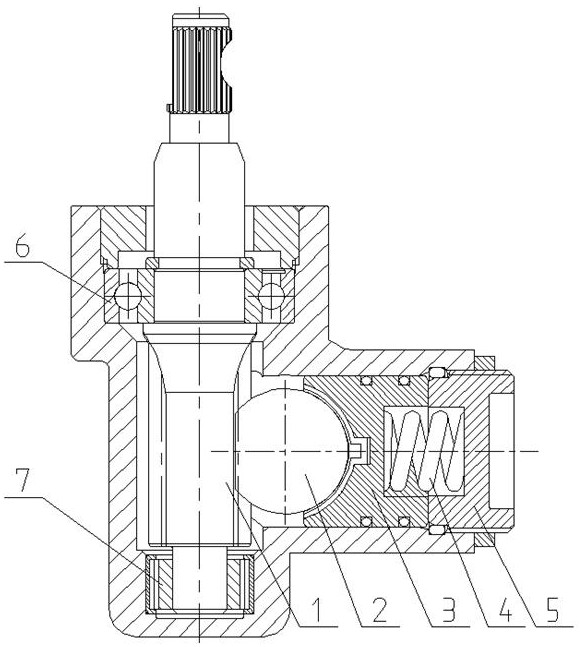

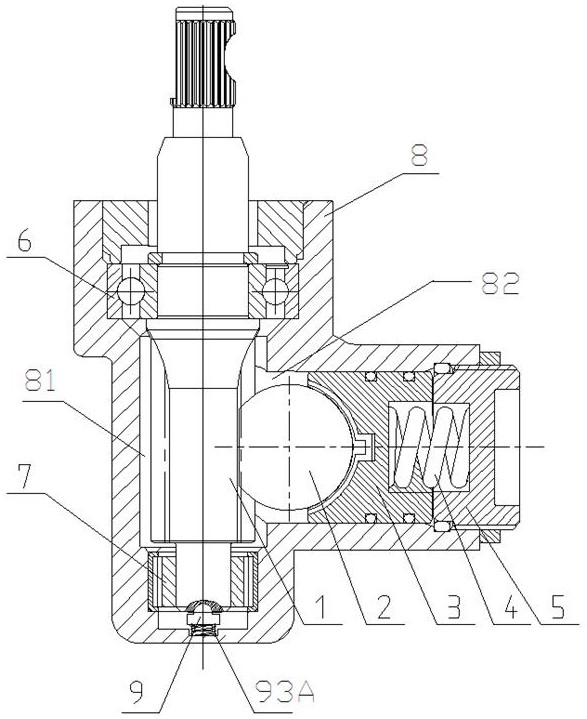

A gear shaft clearance adjustment structure of a steering gear

A gap adjustment and gear shaft technology, which is applied to mechanical steering gears, belts/chains/gears, components with teeth, etc., can solve the problems that the steering gear cannot be further improved, and the impact noise of gear shafts cannot be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

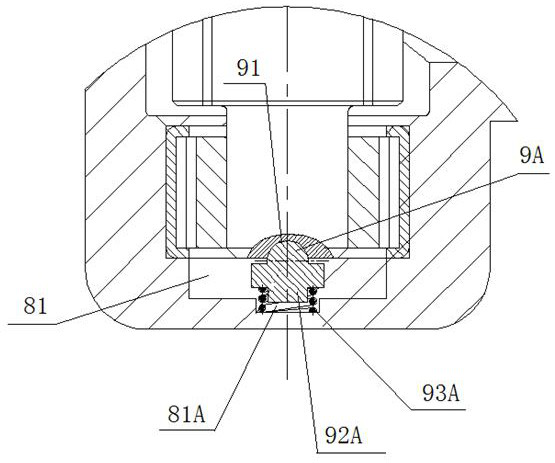

[0021] like image 3 As shown, as a preferred embodiment, the top of the support base 9 is provided with a hemispherical convex portion 9A, and the supporting arc surface 91 is the surface of the hemispherical convex portion 9A. Preferably, the elastic structure includes a connecting column 92A and a spring 93A arranged at the bottom of the support seat 9, the end surface of the gear shaft hole 81 is provided with a counterbore 81A for fixing the spring 93A, the upper end of the spring 93A is socketed with the connecting column 92A, and the spring 93A The lower end is fixed in the counterbore 81A. This type of elastic structure can ensure the stability of the movement of the support seat 9 .

Embodiment 2

[0023] like Figure 4 As shown, as another preferred embodiment, the top surface of the support seat 9 is provided with a hemispherical groove 91B, and a circular steel ball 92B is arranged in the hemispherical groove 91B, and the supporting arc surface is the shape of the circular steel ball 92B. surface. Preferably, the elastic structure includes a diaphragm spring 93B provided at the bottom of the support seat 9, and the end surface of the gear shaft hole 81 is provided with a second counterbore 81B for accommodating the deformation of the diaphragm spring 93B, and the diaphragm spring 93B is overlapped and fixed on the second The opening of counterbore 81B. With this type of elastic structure, the components are easy to assemble, and the possibility of abnormal noise generated by the components of the elastic structure itself can be reduced. Preferably, grease is coated inside the hemispherical groove 91B to increase the rotational flexibility of the round steel ball 92B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com