A cotton filling device capable of making cotton wool fluffy for textile use

A fluffy and cotton-wool technology, applied in applications, household utensils, sewing tools, etc., can solve problems such as low fluffing efficiency, delay in work progress, and inconvenience in later maintenance, so as to improve cleaning efficiency, avoid extrusion, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

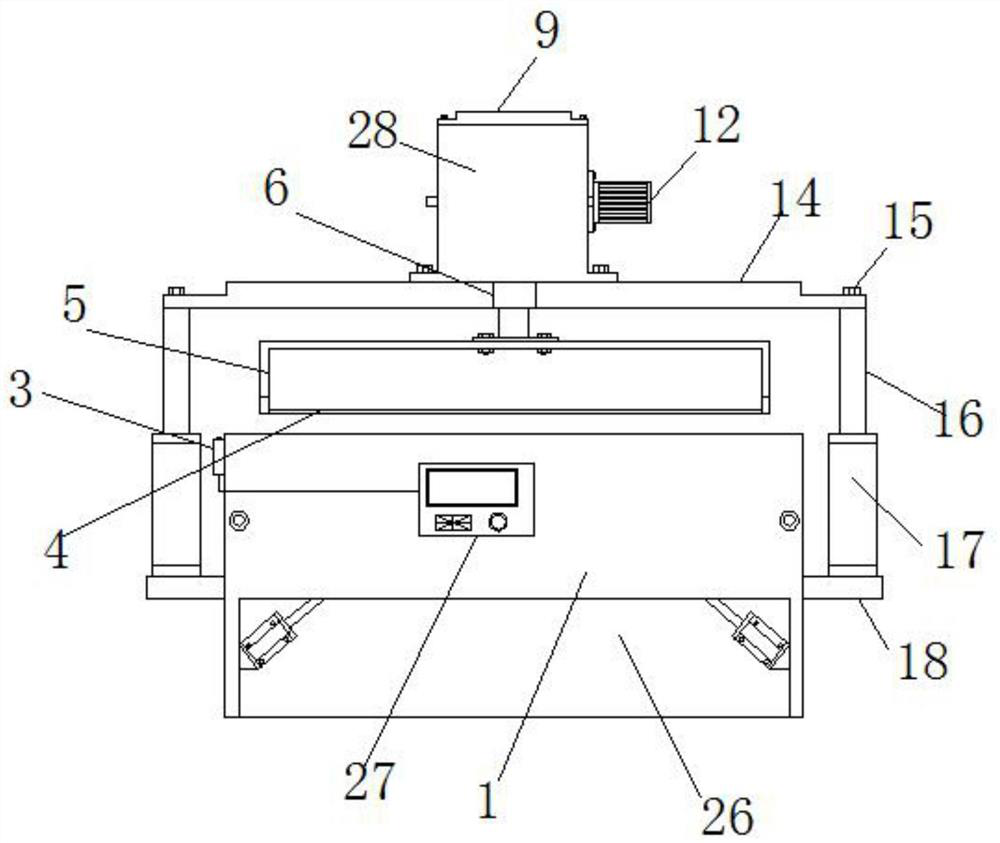

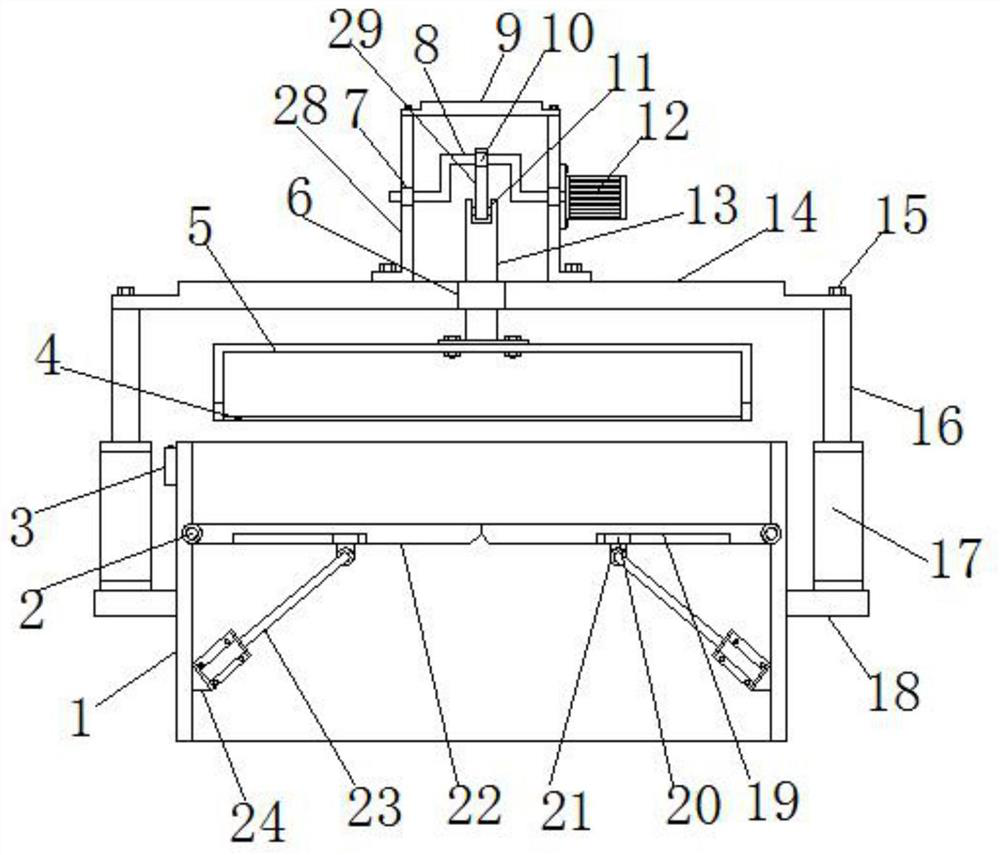

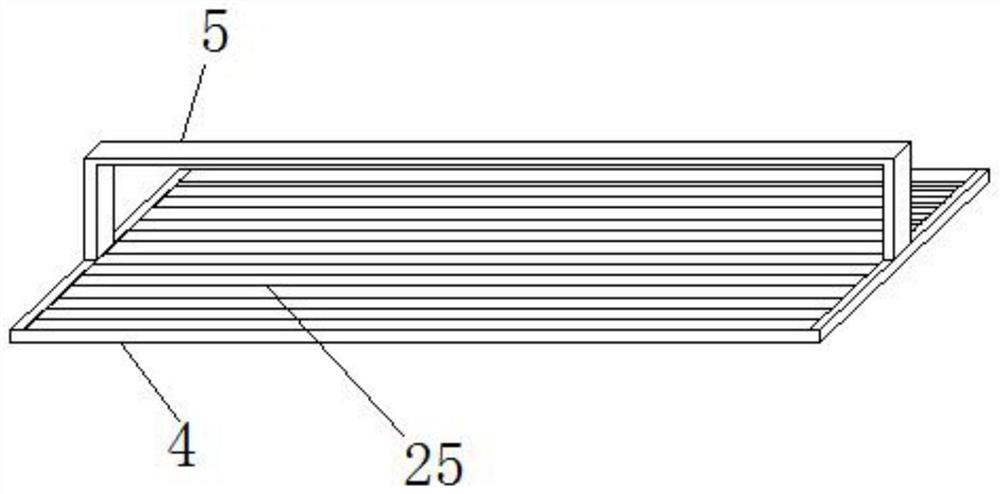

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0026] see Figure 1-6 , the present invention provides a technical solution: a cotton filling device for textile use that can make cotton fluffy, comprising a rectangular cotton filling box 1 and an operating box 28, a PLC controller 27 is fixedly installed in the middle of the front part of the rectangular cotton filling box 1, The PLC controller 27 automatically controls the motor 12, the two cylinders 17 and the two electric push rods 23 to carry out electric control connection, execute the automatic program, and improve the degree of automation. Platform 18, the top of the fixed platform 18 is fixedly installed with a cylinder 17 vertically upwards, a horizontal plate 14 is fixedly connected between the piston rods 16 of the two cylinders 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com