Vortex thickness measuring method

A thickness measurement and eddy current technology, which is applied to eddy current thickness measurement. For the product field with uniform holes on the circumference of the measurement point, it can solve the problems of unreliability and abnormal measurement values, and achieve rapid measurement, reliable results, and operation. logically simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0019] This embodiment provides an eddy current thickness measurement method, which is mainly aimed at products with uniformly distributed holes. The specific measurement steps are as follows:

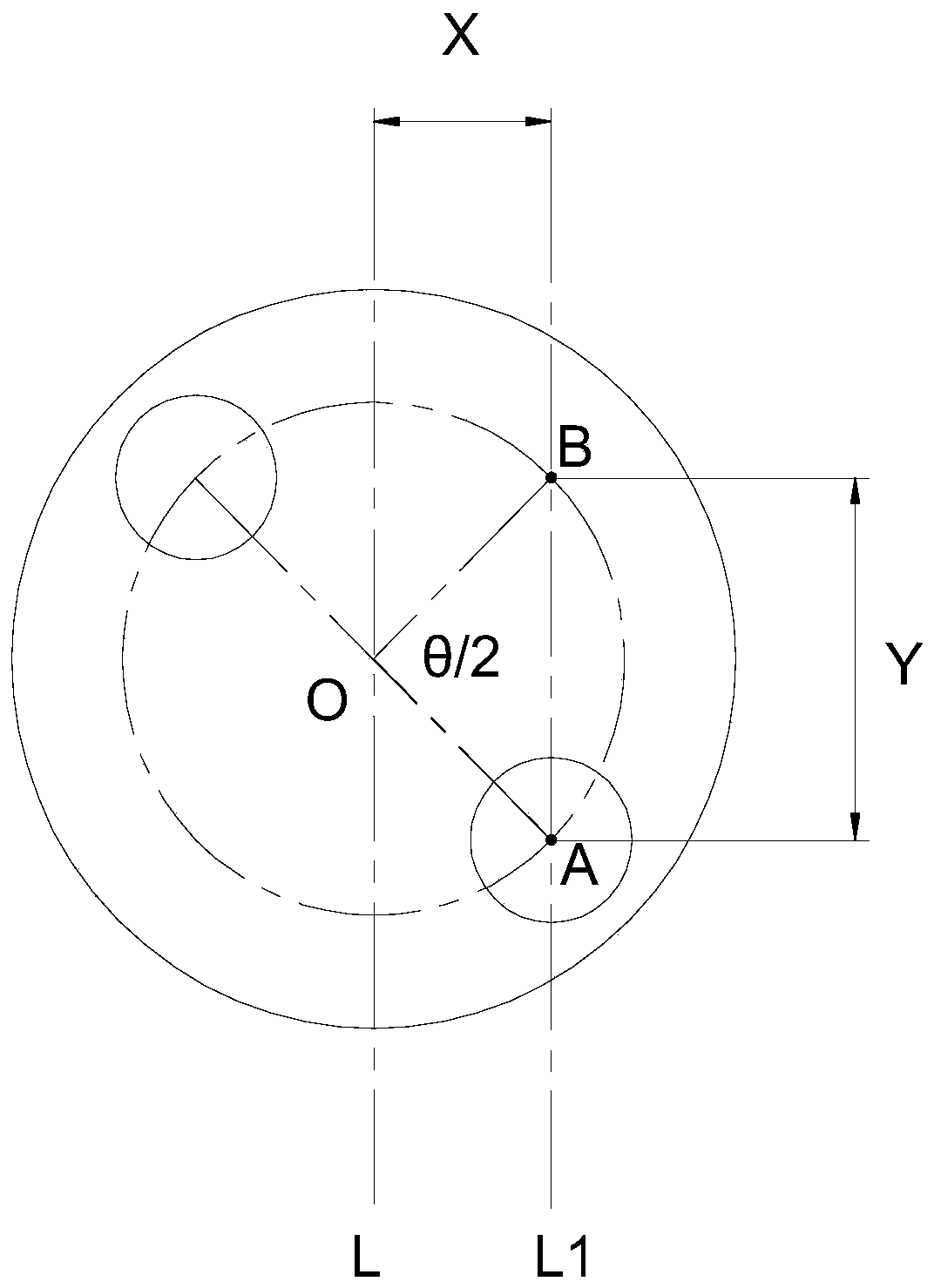

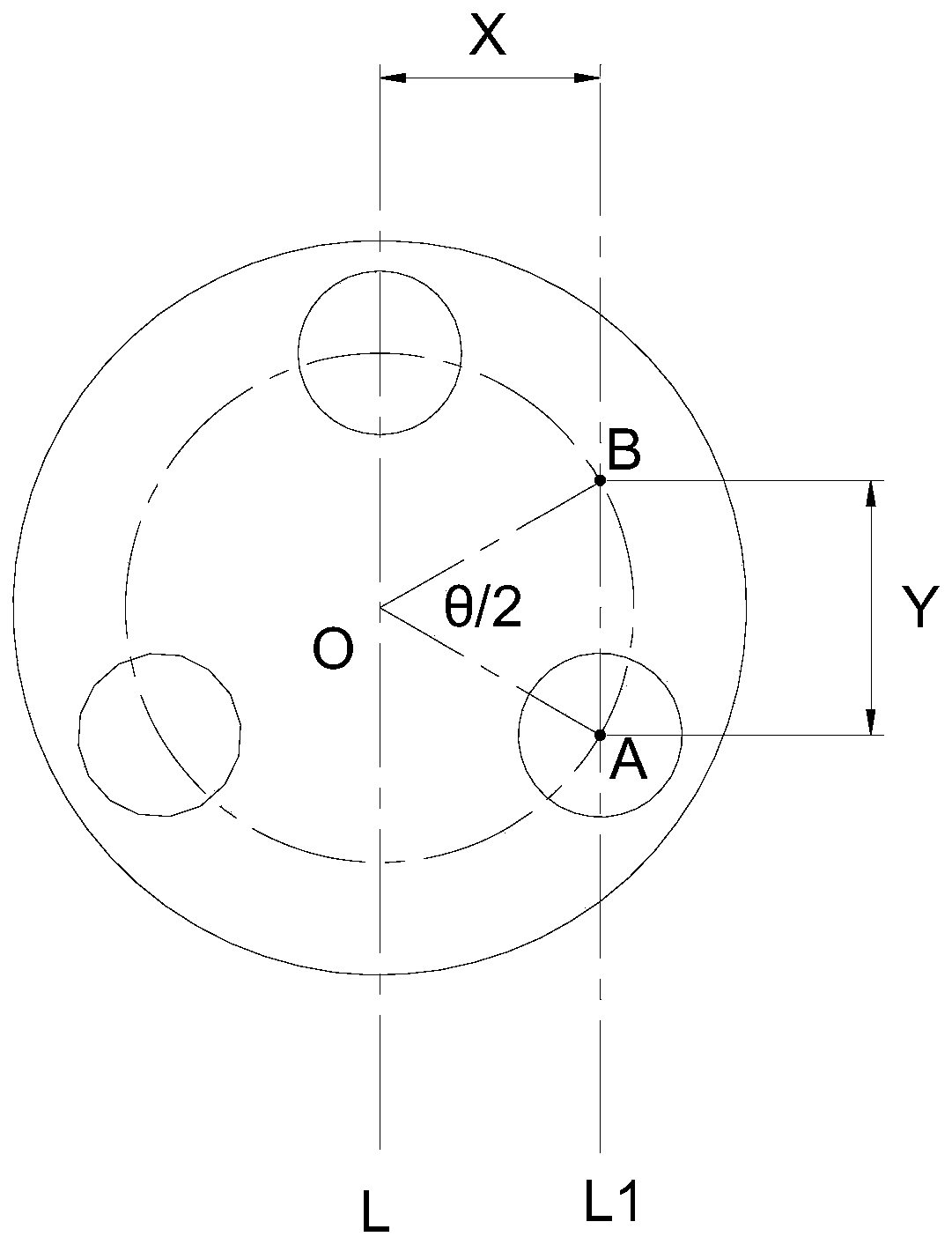

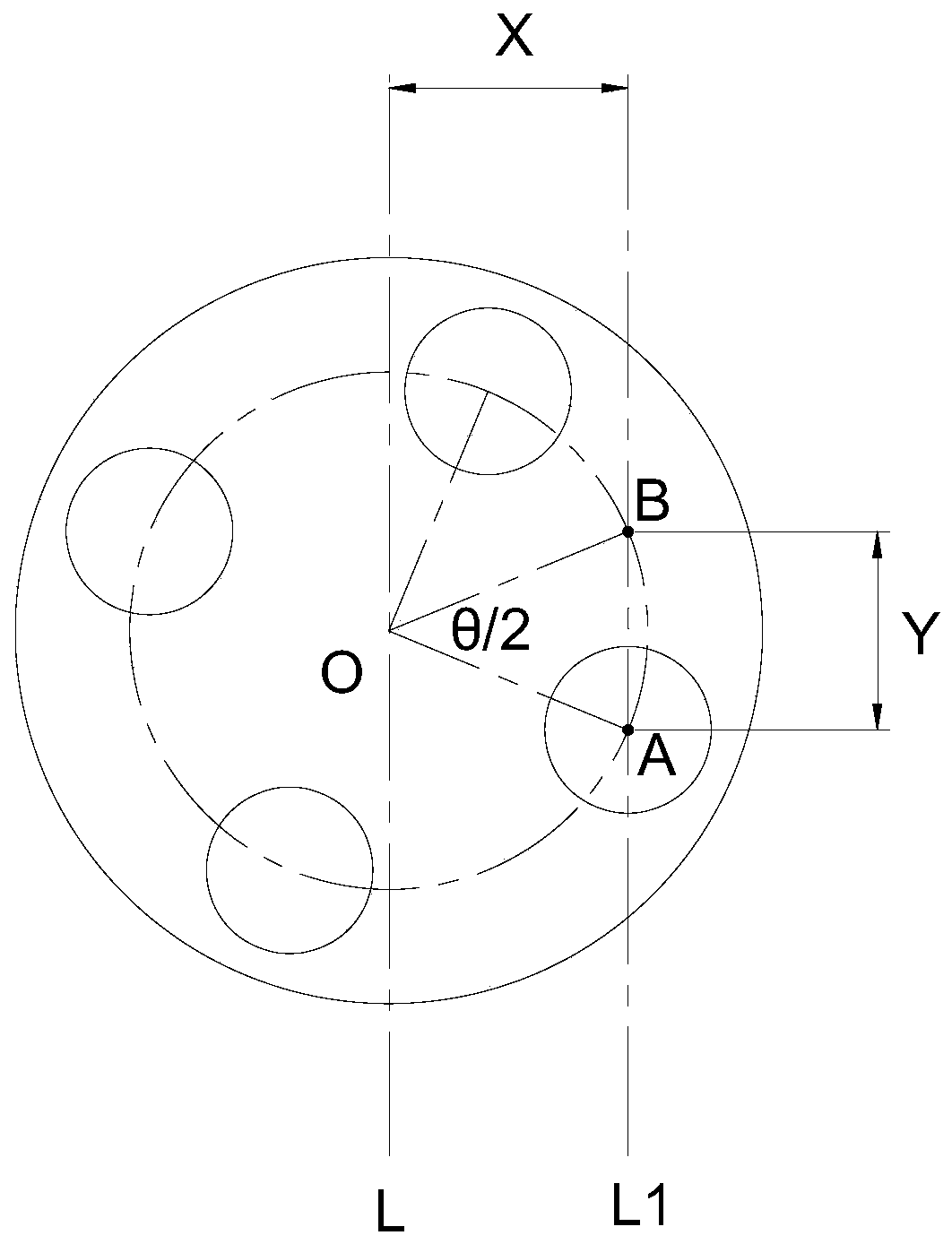

[0020] 1) Take one of the hole center positions as the first measurement point A;

[0021] 2) Determine the center O of the circle where the uniformly distributed holes are located and the center angle θ of the two adjacent holes;

[0022] 3) Rotate the first measurement point A around the center O angle to obtain the second measurement point B;

[0023] 4) Make a central axis L parallel to the line connecting points A and B through the center O of the circle, and obtain the distance X between the line AB and the line L, and obtain the distance Y between points A and B;

[0024] 5) Offset the measurement center axis L by X distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com