Programmable slide rheostat based on stepping motor PLC intelligent control and application method thereof

A technology of sliding rheostats and stepping motors, which is applied in the direction of sliding contact resistors, resistors, adjustable resistors, etc., can solve the problems of unstable adjustment, influence of adjustment accuracy, and single adjustment method, so as to avoid manual adjustment, High-precision automatic control, the effect of automatic resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

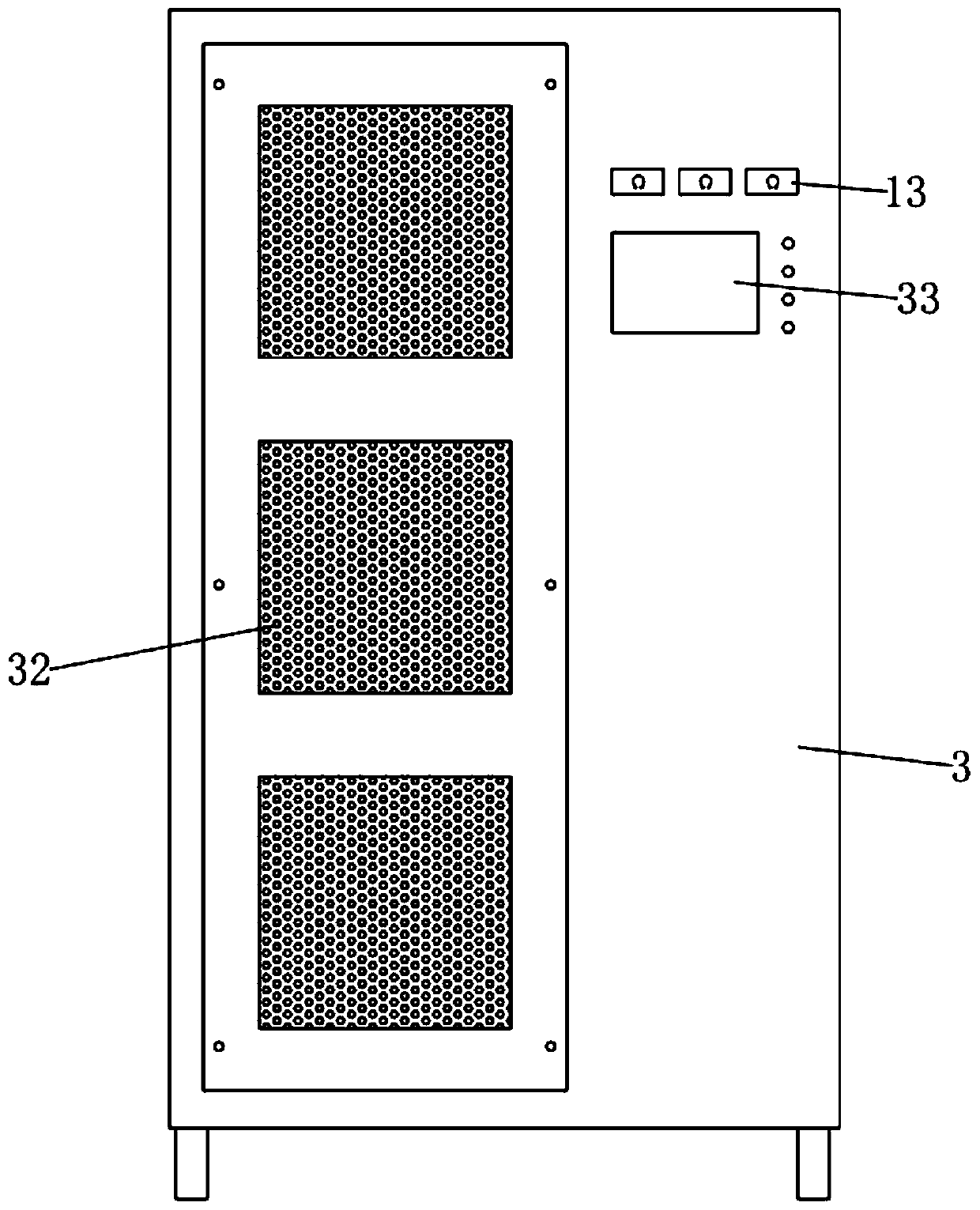

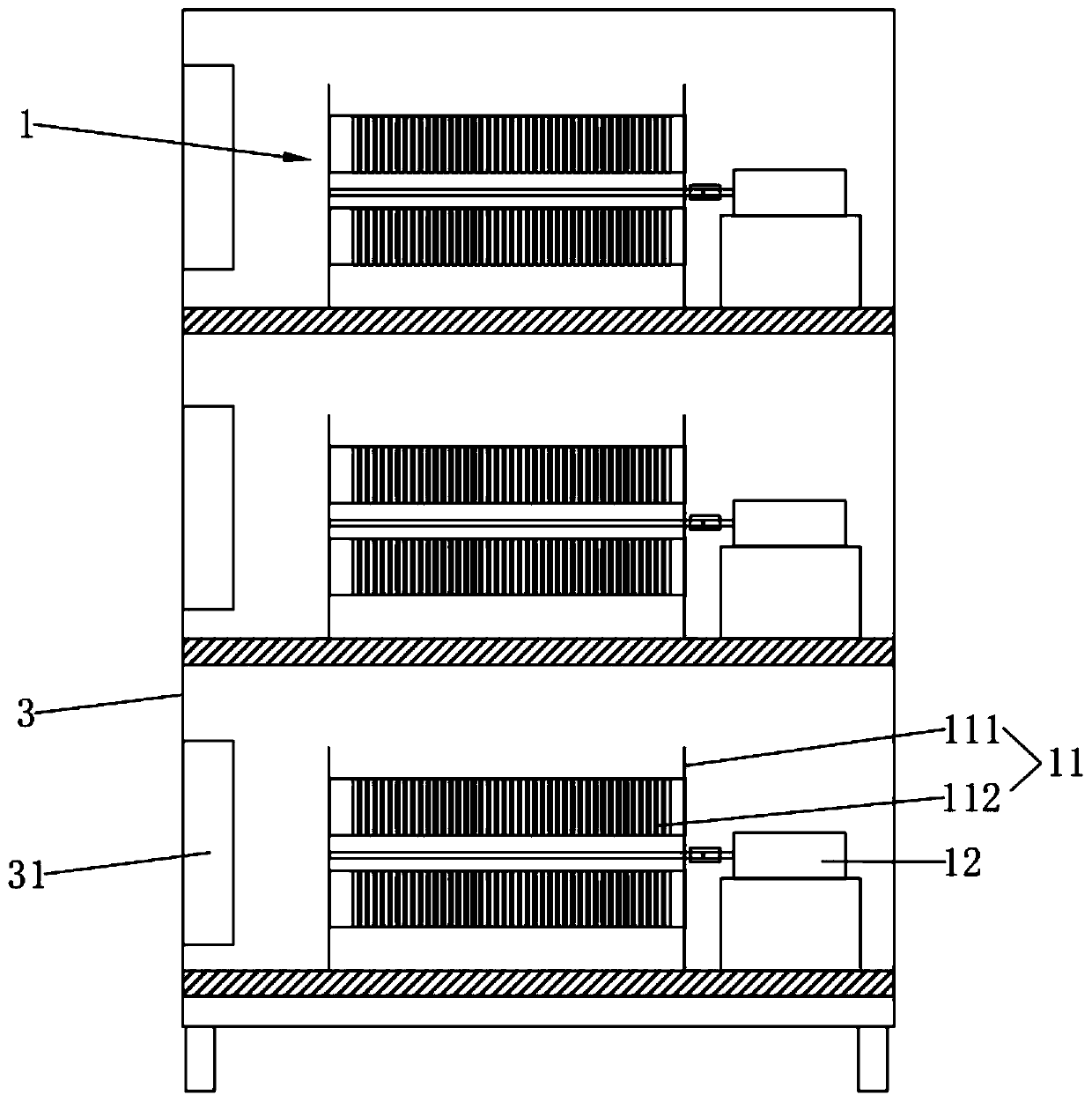

[0038] A programmable sliding rheostat based on stepping motor PLC intelligent control, such as Figure 1 to Figure 7 As shown, the varistor module 1 and the PLC control module 2 are included; in use, the PLC control module 2 controls the varistor module 1 to exhibit different resistance values.

[0039] The varistor module 1 includes a varistor 11, a driving component 12, and a resistance value sampling module 13. The driving component 12 is used to automatically drive the varistor 11, so that the varistor 11 exhibits different resistance values. The resistor sampling module is used to measure the resistance of the varistor 11.

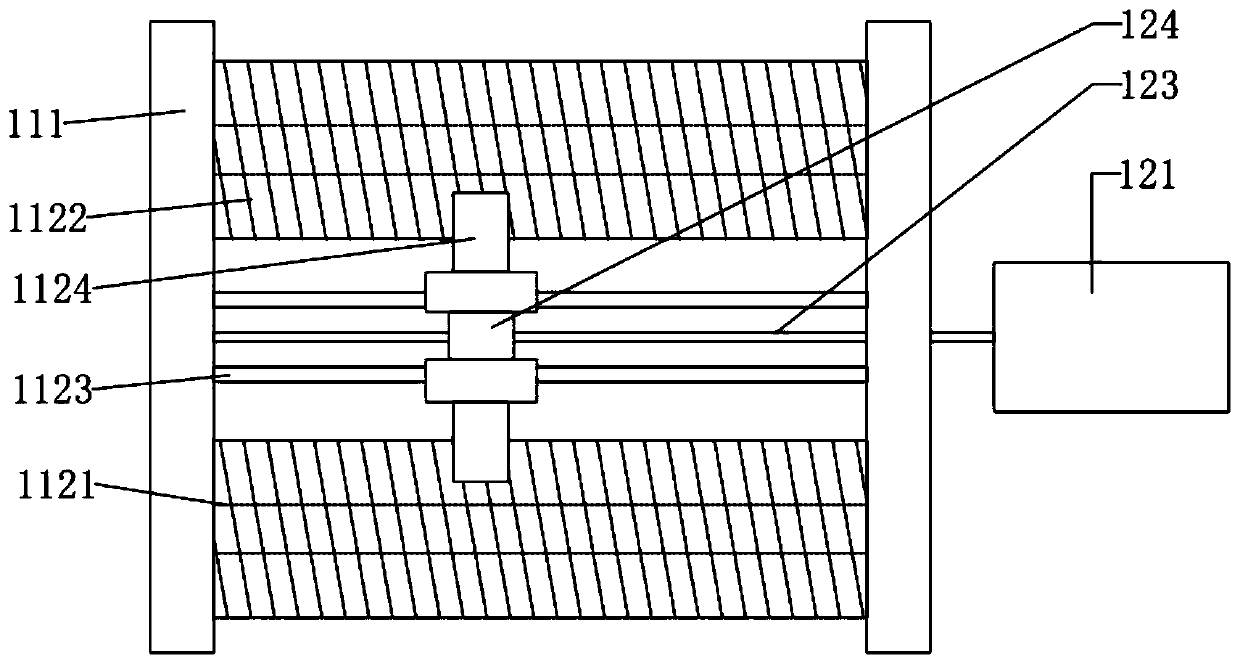

[0040] The varistor 11 includes a supporting plate 111 at both ends, a supporting shaft 1121 arranged between the two supporting plates 111, a resistance wire 1122 wound on the supporting shaft 1121, a sliding rod 1123 arranged between the two supporting plates 111, and a A freely slidable sliding contact block 1124 on the sliding rod 1123, one end of th...

Embodiment 2

[0050] A method for using a programmable sliding rheostat based on the PLC intelligent control of a stepping motor, including the following steps:

[0051] S1. Set the resistance value on the touch screen 33, and the PLC control module 2 controls the ohmmeter to measure the actual resistance value;

[0052] S2, PLC control module 2 compares the set resistance with the measured actual resistance;

[0053] S3. The PLC control module 2 controls the forward and reverse controller 122 to make the stepping motor 121 forward or reverse;

[0054] S4. The ohmmeter measures the actual resistance value, and the PLC control module 2 performs a second comparison between the set resistance value and the measured actual resistance value;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com