Efficient energy-saving circular tube inner wall polishing grinding machine

A high-efficiency and energy-saving technology for polishing and grinding, which is applied in the direction of grinding frame, grinding/polishing equipment, grinding/polishing safety device, etc. problem, to achieve the effect of low equipment manufacturing cost, good practical value and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

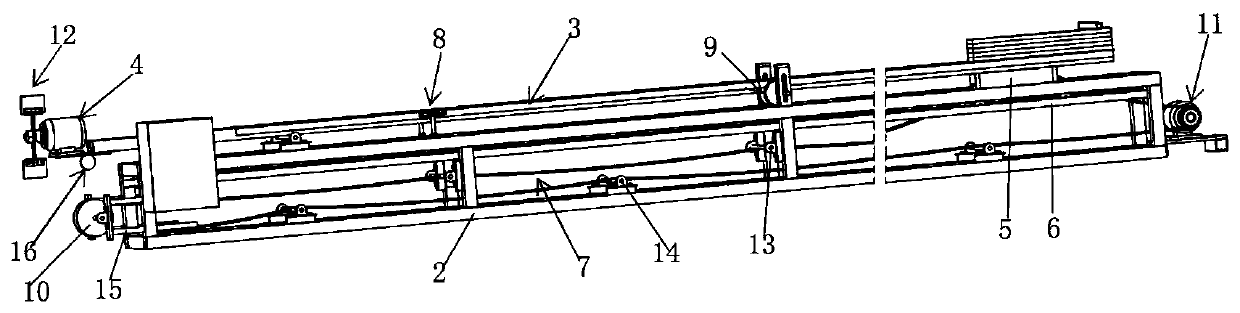

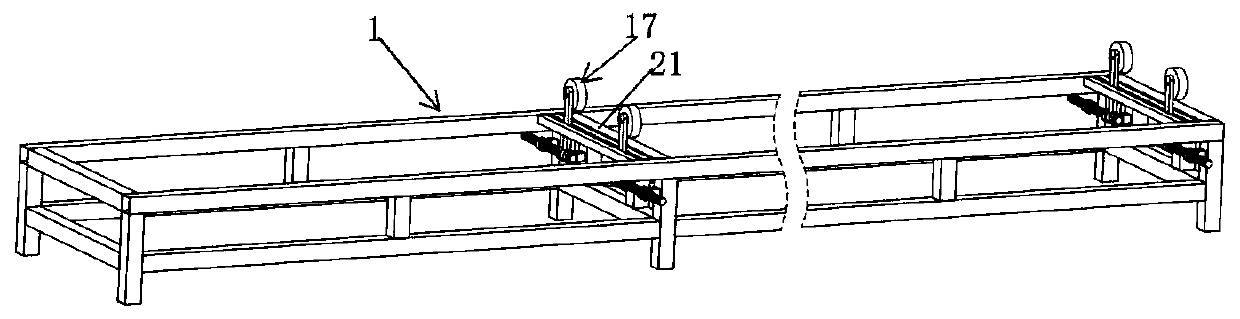

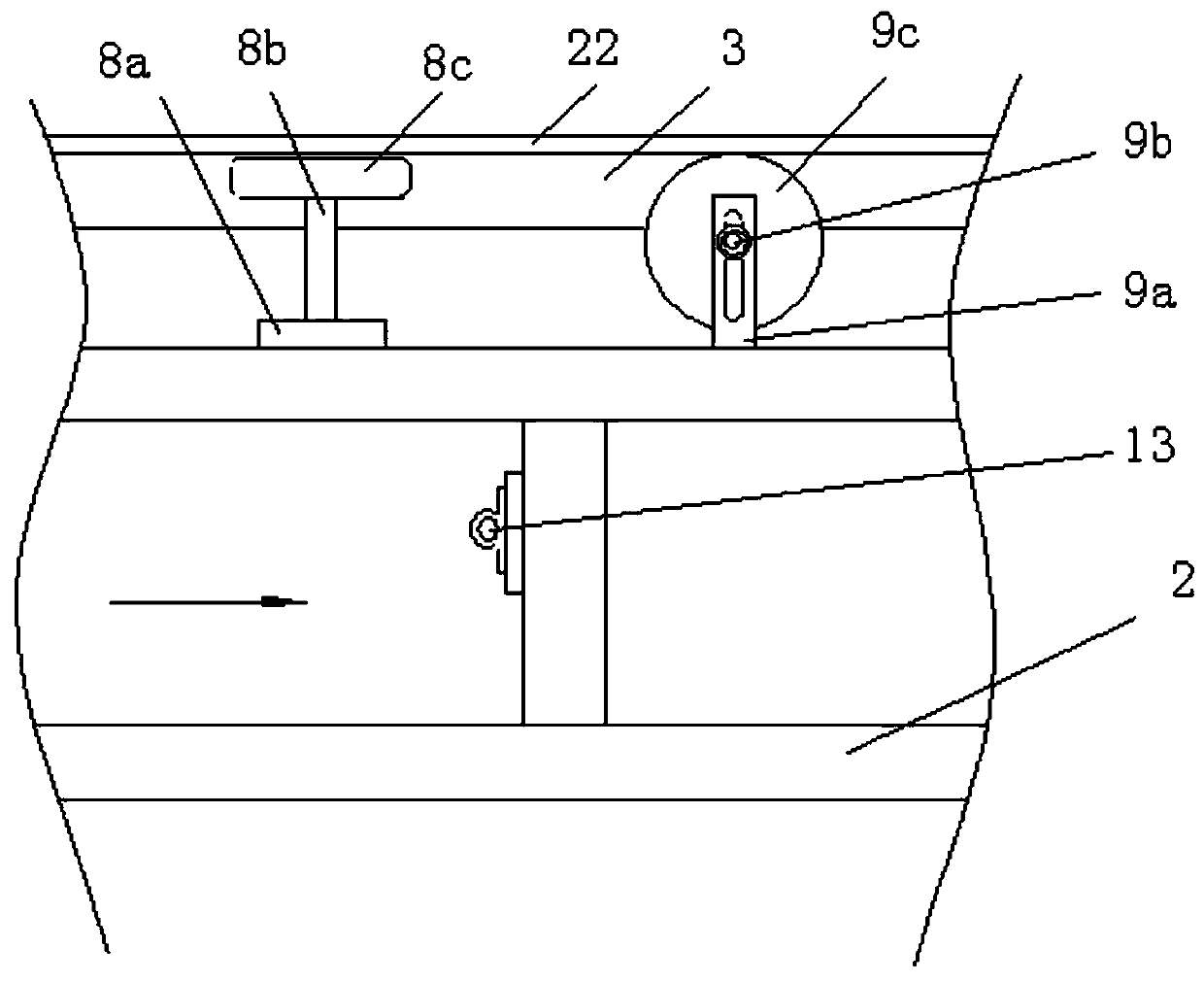

[0031] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , in the figure, 1-worktable, 2-support frame, 3-moving rod, 4-grinding motor, 5-moving trolley, 6-track, 7-ring chain, 8-horizontal limit device, 9-vertical limit Bit device, 10-reversing wheel, 11-reducer, 12-sandpaper, 13-upper roller, 14-lower roller, 15-adjusting screw, 16-support wheel, 17-support adjustment wheel, 18-support rod , 19-screw, 20-adjusting bolt, 21-limiting square tube, 22-baffle;

[0032] 8a-horizontal plate, 8b-horizontal screw shaft, 8c-horizontal roller, 8d-horizontal strip hole; 9a-vertical plate, 9b-vertical screw shaft, 9c-vertical roller, 9d-vertical strip hole .

[0033] The high-efficiency and energy-saving round tube inner wall polishing machine includes a worktable, a support frame, a grinding motor and sandpaper. The workbench and the support frame are set correspondingly, and the two are on the same straight line. The support frame is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com