Mechanically-driven random speed change linear motion device

A technology of linear motion and mechanical transmission, applied in the direction of electromechanical devices, control mechanical energy, electric components, etc., can solve the problems of large volume, complex structural system, high failure rate, etc., achieve small space occupied by the mechanism, and solve complex structural systems , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

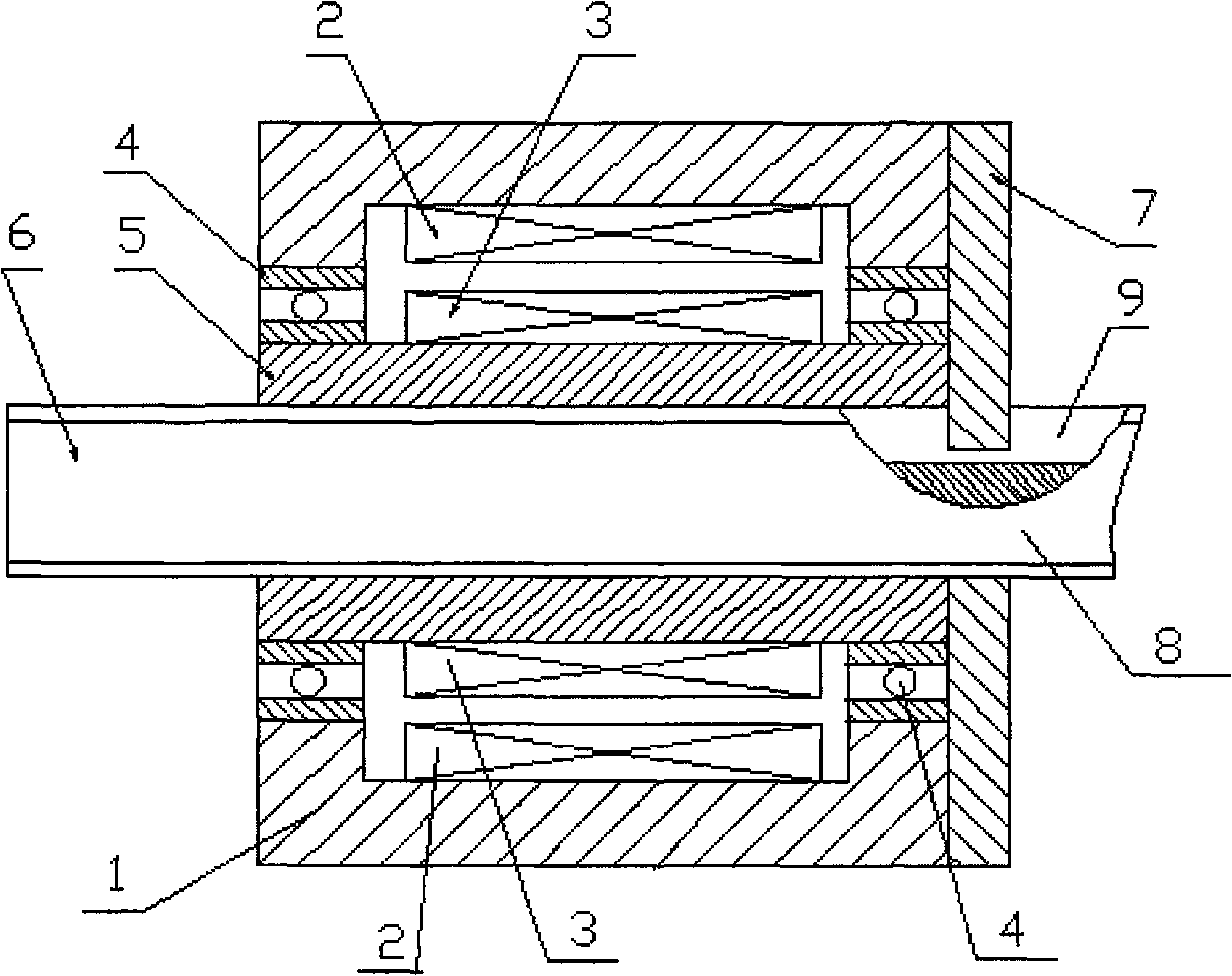

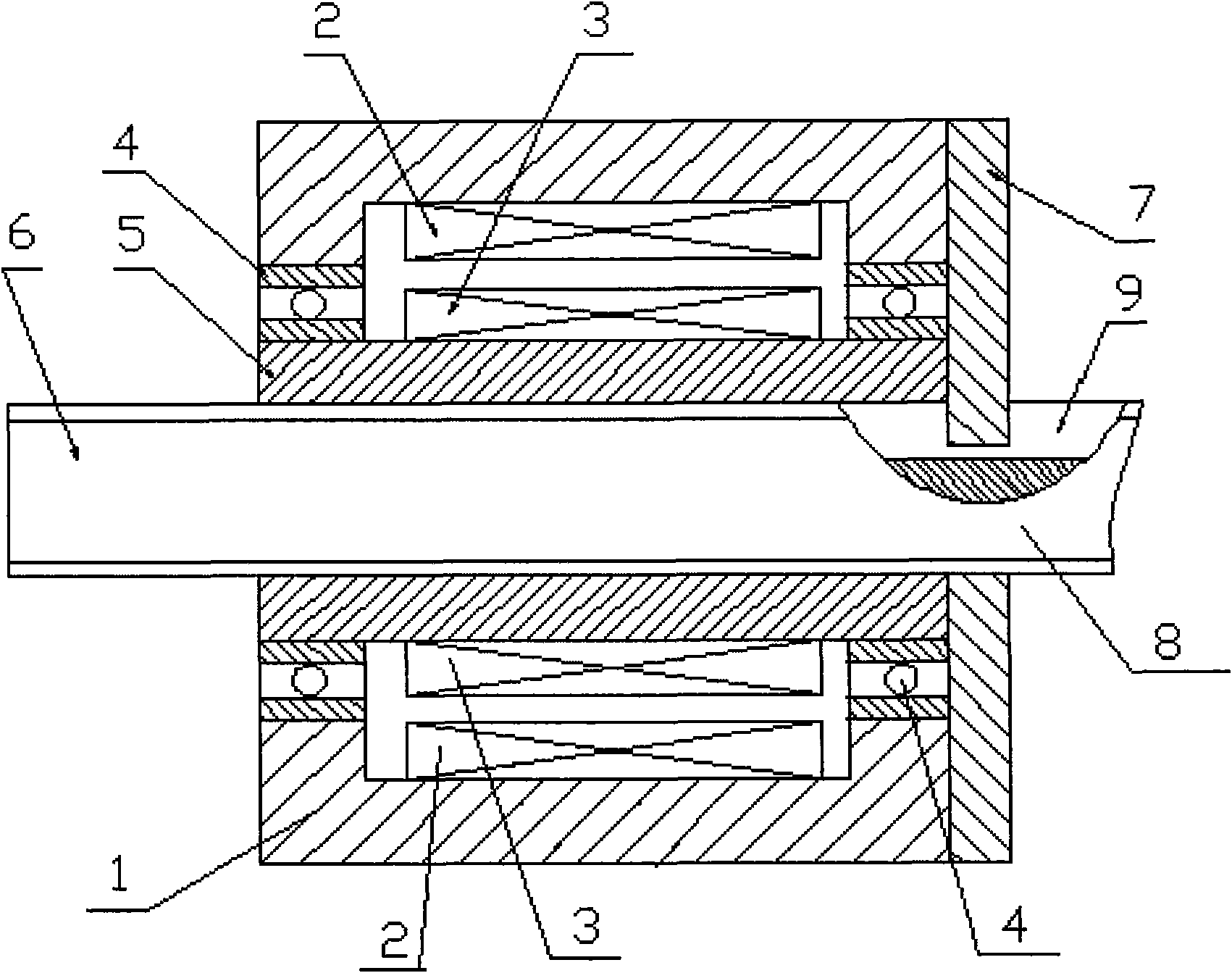

[0009] A variable frequency motor is composed of a base (1), a variable frequency coil winding (2), a rotor (3), a bearing (4), and a hollow shaft (5), and the hollow shaft (5) is located on the outer circle inside the base The fixed rotor (3) is installed, the hollow shaft (5) is installed on the support (1) through the bearing (4), and the internal thread of the corresponding specification is produced on the hollow inner circle of the hollow shaft (5), and the leading screw ( 6) on the outer circle of the hollow shaft, an external thread of the same specification as the hollow inner circle of the hollow shaft is produced, and the leading screw (6) is screwed into the internal thread of the hollow shaft (5) through the external thread on it, and the leading screw (6) ) is made on the outer circle of the chute (9) parallel to its axis, the middle of the stop plate (7) is a hole similar to the cross-sectional shape of the lead screw, and its protruding anti-rotation tongue (8) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com