Differential clamping inchworm-type piezoelectric linear motor

A linear motor, clamping technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as unstable contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

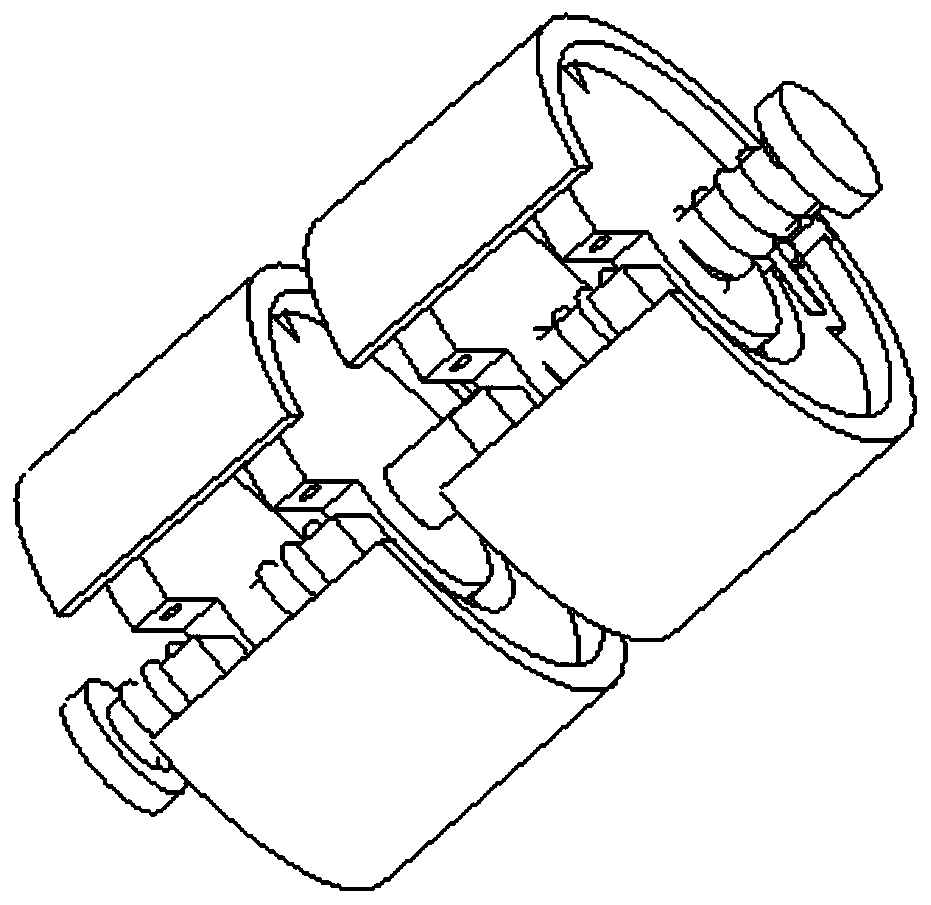

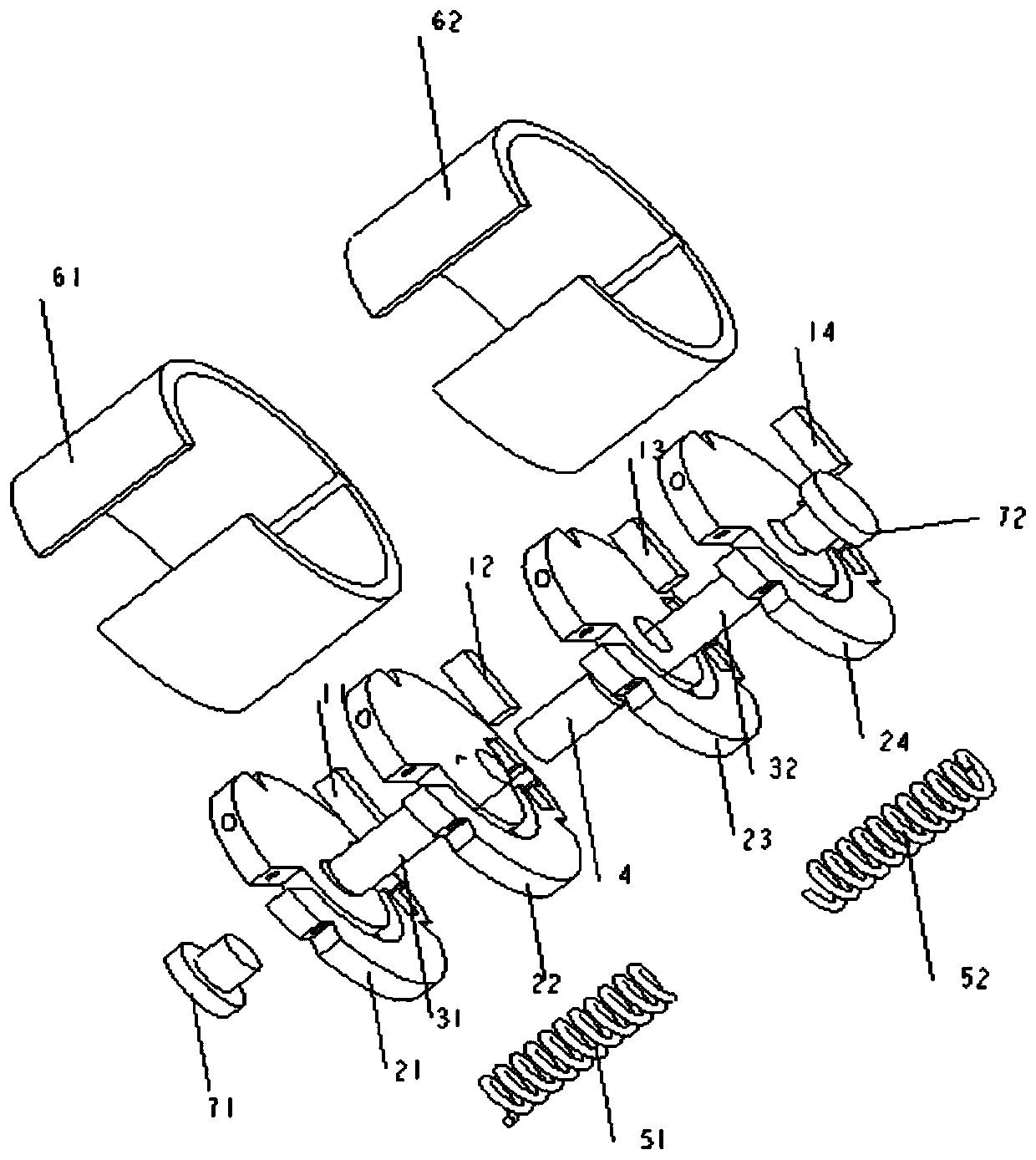

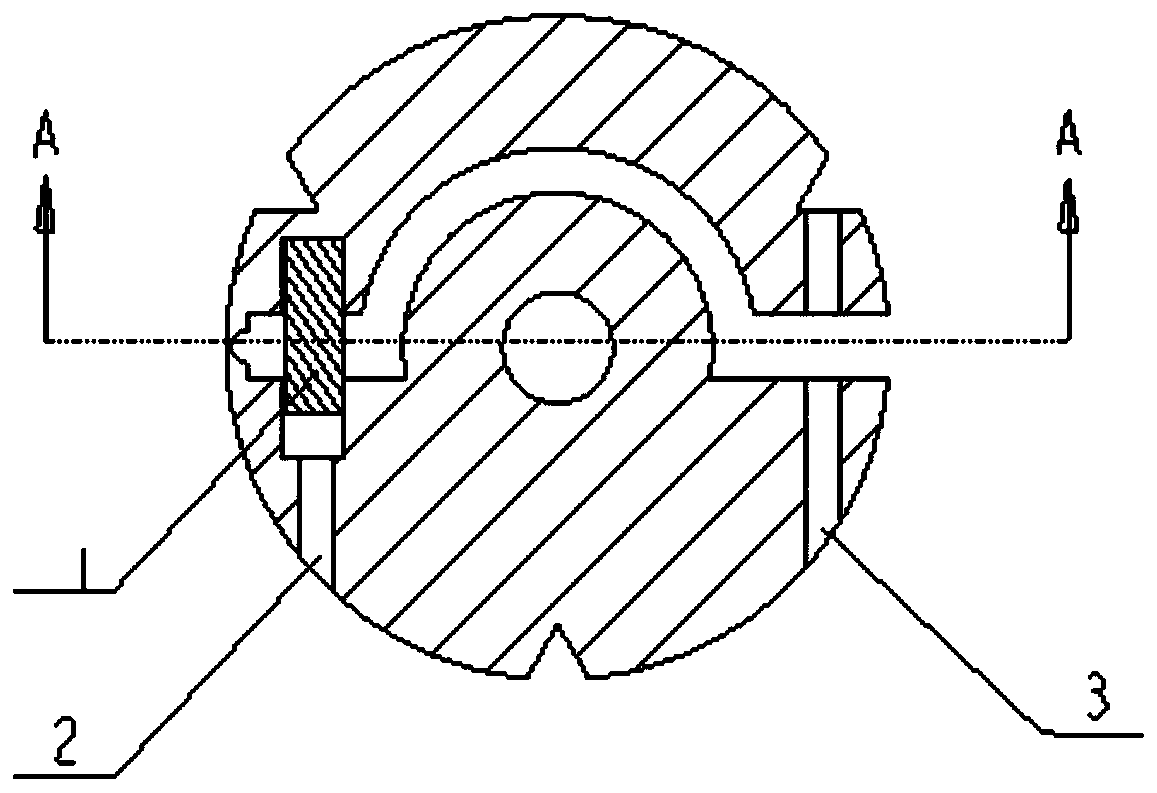

[0021] Please check Figure 1 to Figure 4 , Differential clamping inchworm type piezoelectric linear motor, including four clamping discs 21,22,23,24, an actuation module 4, two guiding mechanisms, two connecting rods 31,32 and two connecting springs 51,52.

[0022] The four clamping discs 21, 22, 23, 24, two connecting rods 31, 32 and two connecting springs 51, 52 form two units, and each unit includes two clamping discs, a connecting rod and a connecting spring. The four clamping discs 21, 22, 23, 24 are all provided with central holes, and the two clamping discs of each unit are sleeved on the connecting rod through the central holes, and the two clamping discs of each unit are also connected by connecting springs. The two clamping discs included in each unit are divided into a main clamping disc and an auxiliary clamping disc, the main clamping disc is fixedly connected to the actuating module 4, and the auxiliary clamping disc is connected with the main clamping disc thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com