Heating device and spraying type gluing machine

A technology of heating device and gluing machine, which can be applied to the device for coating liquid on the surface, coating, surface pretreatment, etc., and can solve the problem of uneven heating and drying of the heating device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

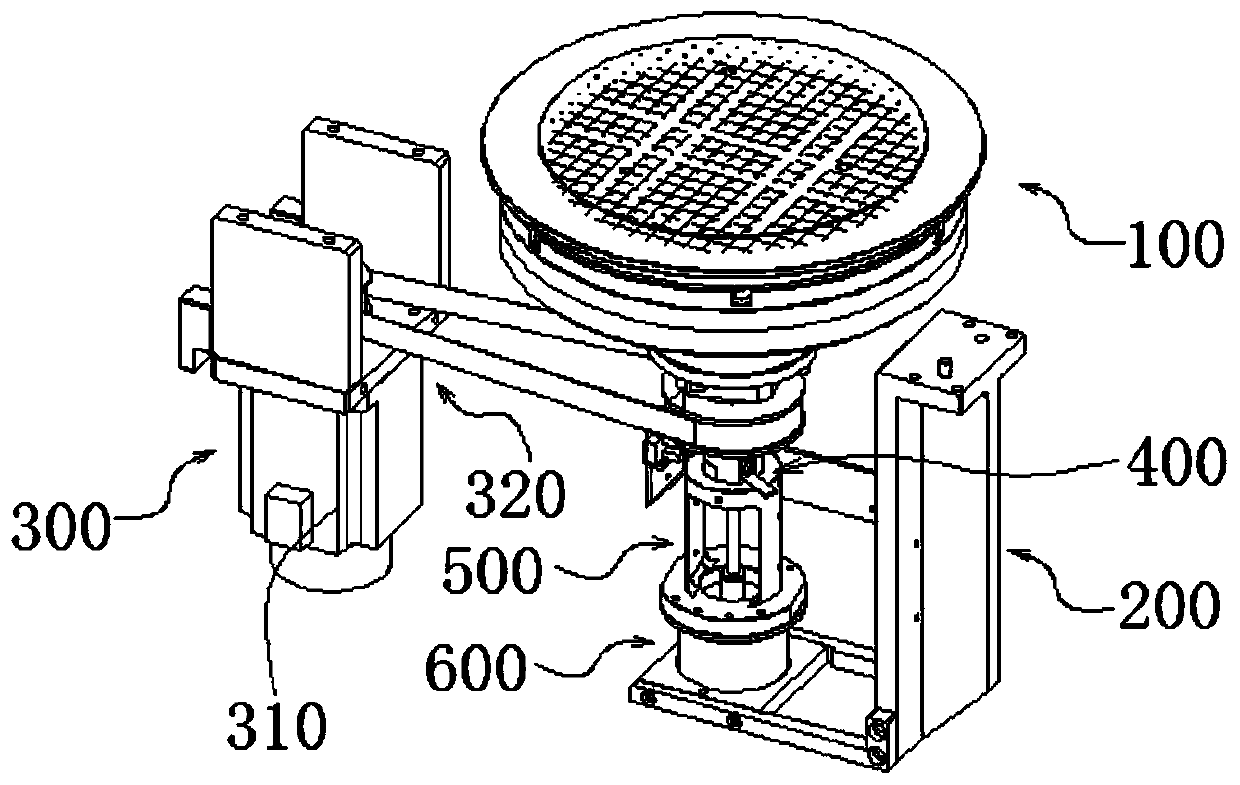

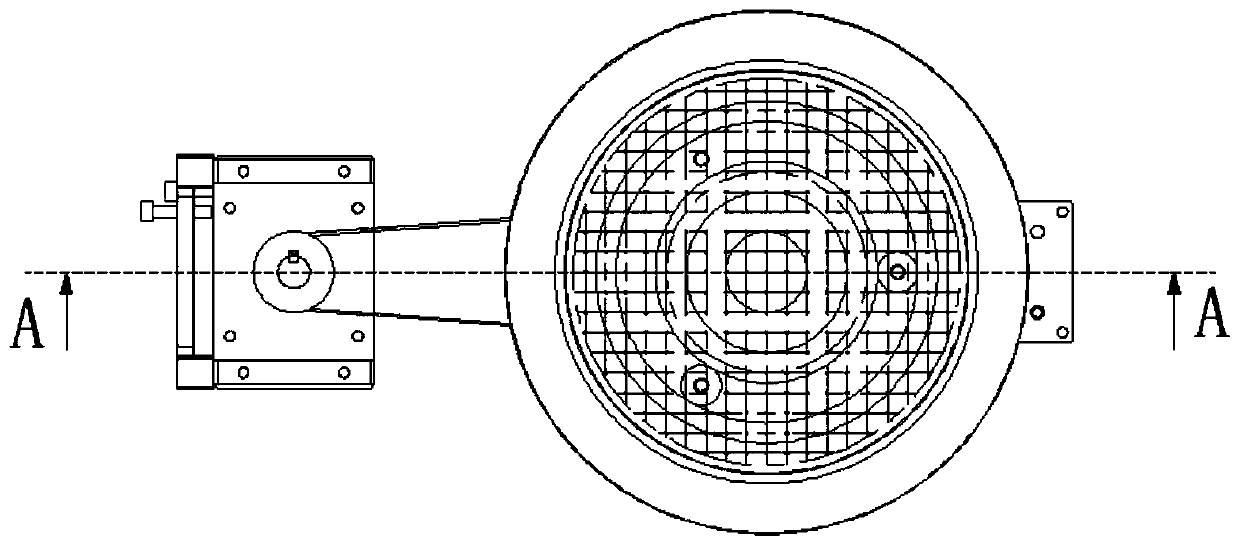

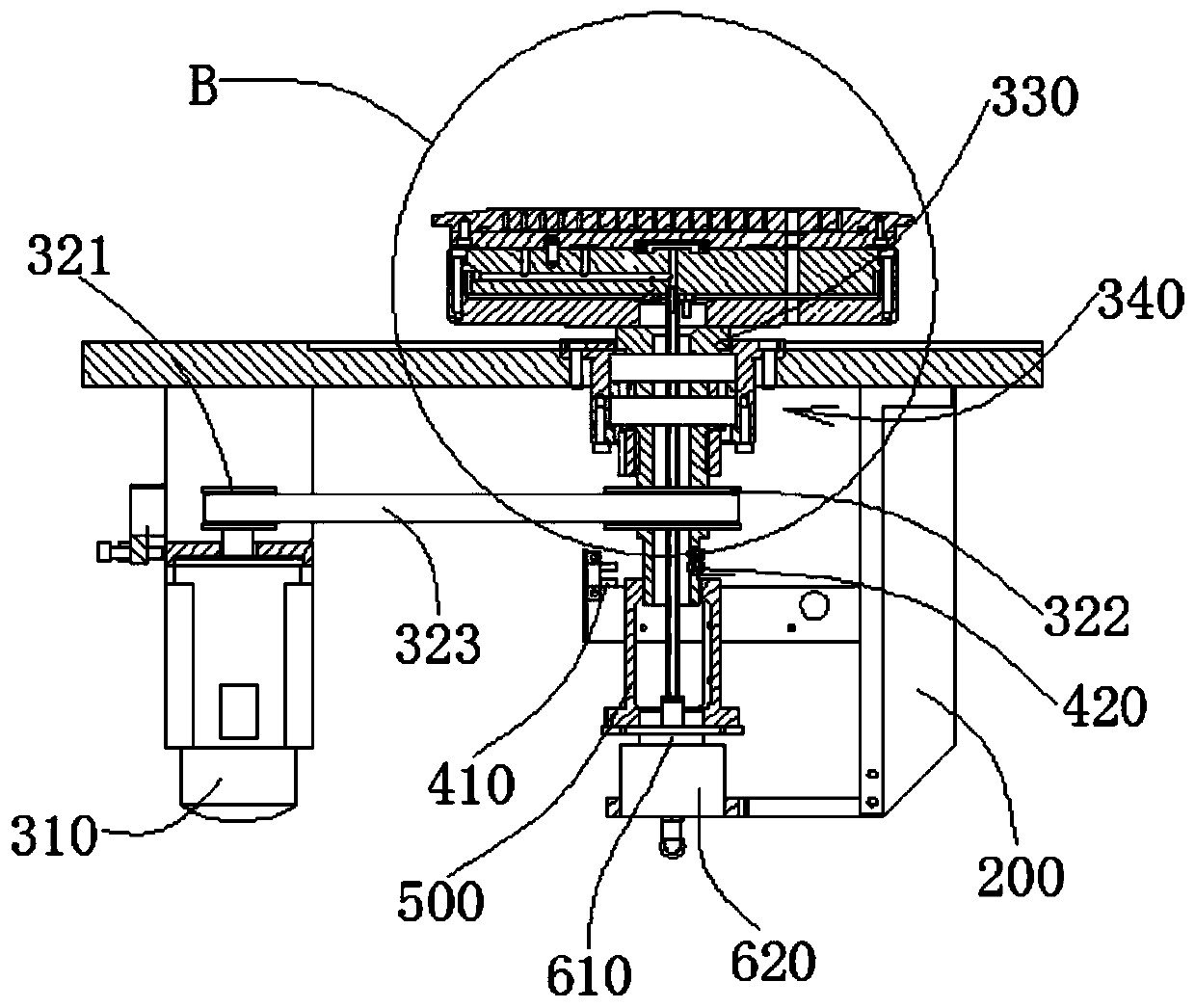

[0041] This embodiment provides a heating device, such as Figure 1 to Figure 4 As shown, the heating device 100 includes a heating plate 120 and a suction cup 130, and the heating plate 120 is arranged opposite to the suction plate 130; the heating plate 120 is divided into a plurality of heating zones, and each heating zone is correspondingly provided with a heating element, and a plurality of heating zones correspond to a heating element. As for the heating surface, the sucker has a heating surface, and the heat transfer surface is arranged opposite to the heating surface, and surface contact is adopted between the two surfaces.

[0042] In the heating device, a heating element is arranged in the heating plate 120 , and the heating element will generate heat when it works, and the heat can be transferred from the heating plate 120 to the suction cup 130 , so as to realize heating or drying of the product adsorbed on the suction cup 130 . During this process, since the hot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com