Method for machining stepped hole with large depth-diameter ratio

A processing method and step hole technology, applied in the direction of metal processing equipment, manufacturing tools, workpiece feed movement control, etc., can solve the problems of saddle shape and taper error, uneven material removal, etc., to eliminate the dependence on the technical level , easy to automate processing, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

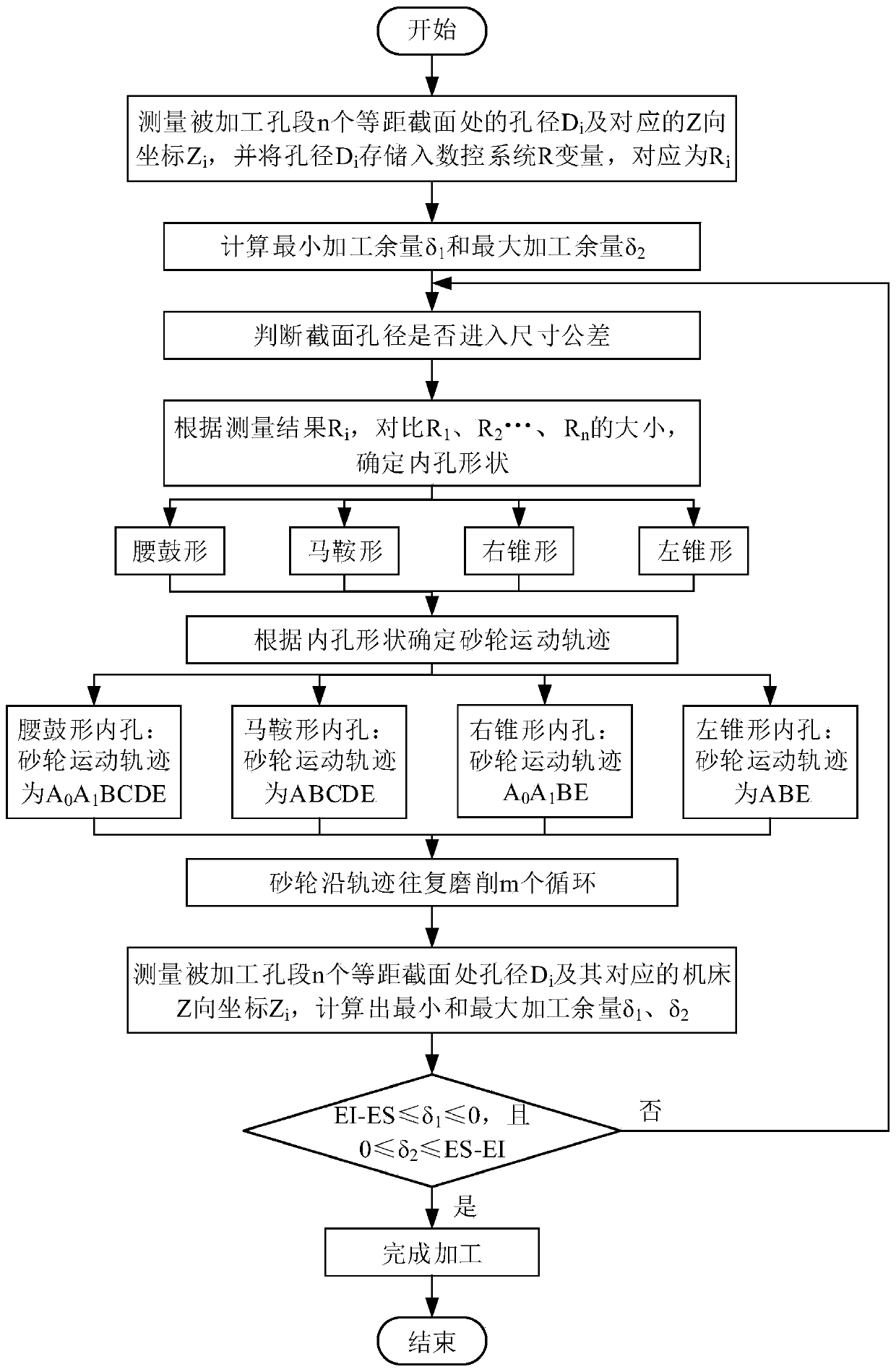

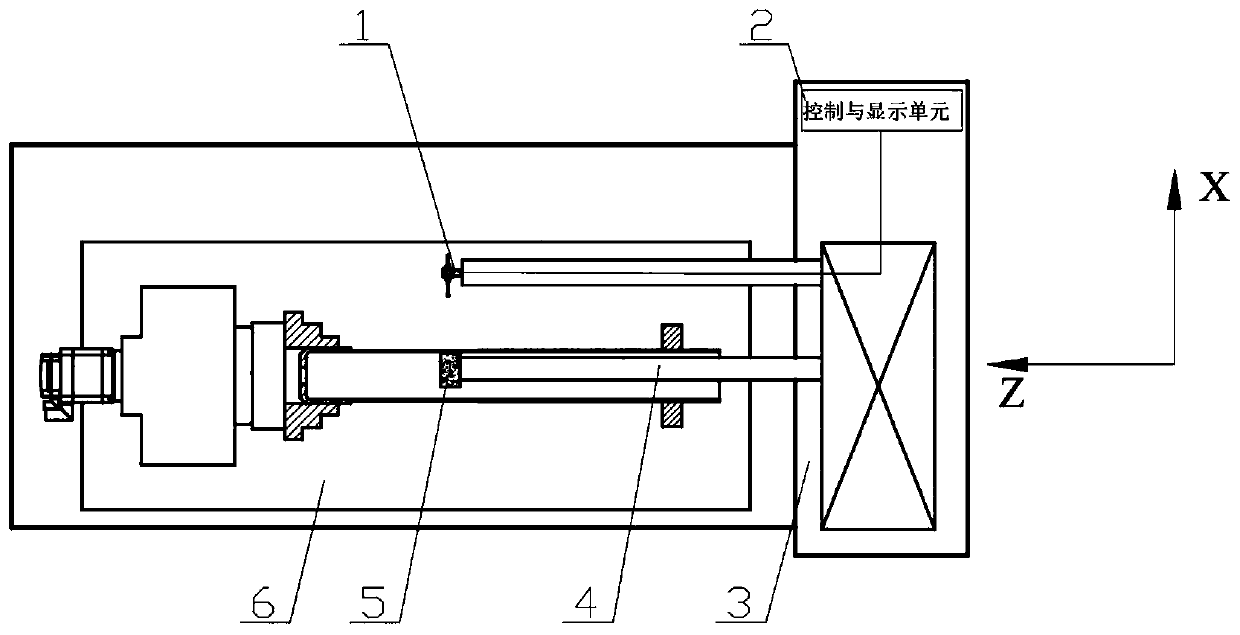

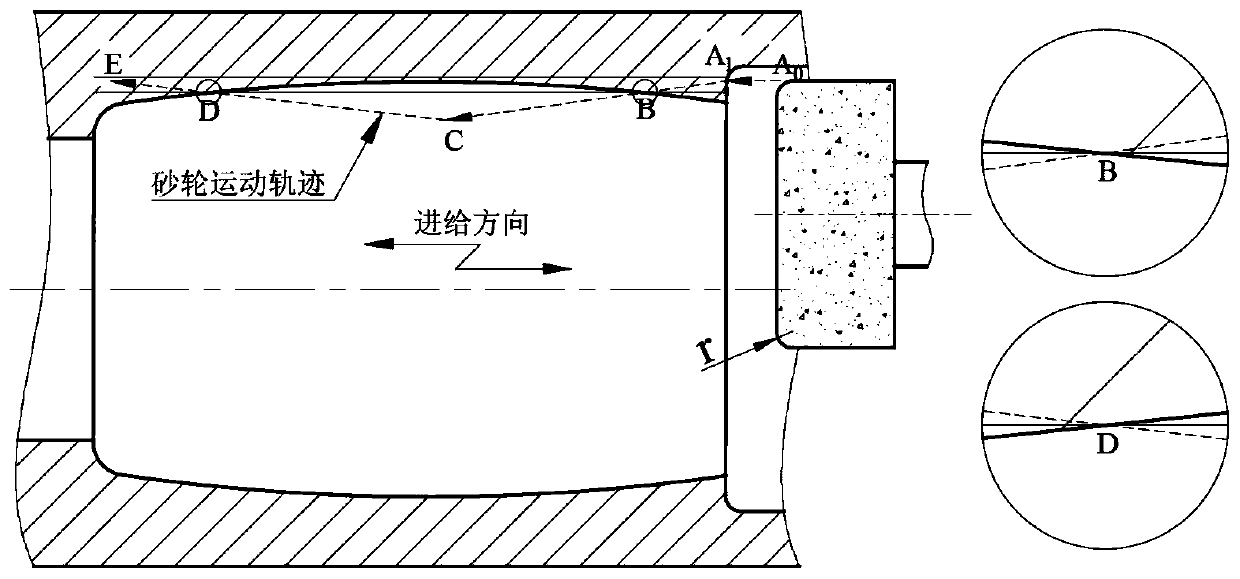

[0059] S1. Measuring the apertures at different sections of the processed hole section: divide the processed hole section into n equidistant sections, n is preferably an odd number, control the feed of the X-axis workbench 3 and the Z-axis workbench 6 of the machine tool, and measure the Aperture D at each sectioni And the corresponding machine tool Z coordinate Z i , from the orifice to the bottom of the hole i=1,2,...,n, the measurement result D i Sequentially write the R variable of the CNC system for storage, and the corresponding R parameter is R i , where i=1,2,...,n;

[0060] S2. Calculation of machining allowance: According to the processing requirements of inner hole cylindricity, the basic dimension D 0 and the tolerance E(ES, EI) requirements, determine the upper limit size D of the theoretical aperture max =D 0 +ES, and lower limit dimension D min =D 0 +EI, calculate the minimum machining allowance δ 1 =D min -max(D i ), the maximum machining allowance δ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com