Preparation method of modified natural graphite for lithium ion battery

A lithium-ion battery and natural graphite technology, which is applied in the field of lithium-ion battery negative electrode material processing, can solve the problems of voids and spherical natural graphite being difficult to achieve uniform coating, achieve large diffusion coefficient, enhance rate performance and cycle performance, and enhance fast The effect of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

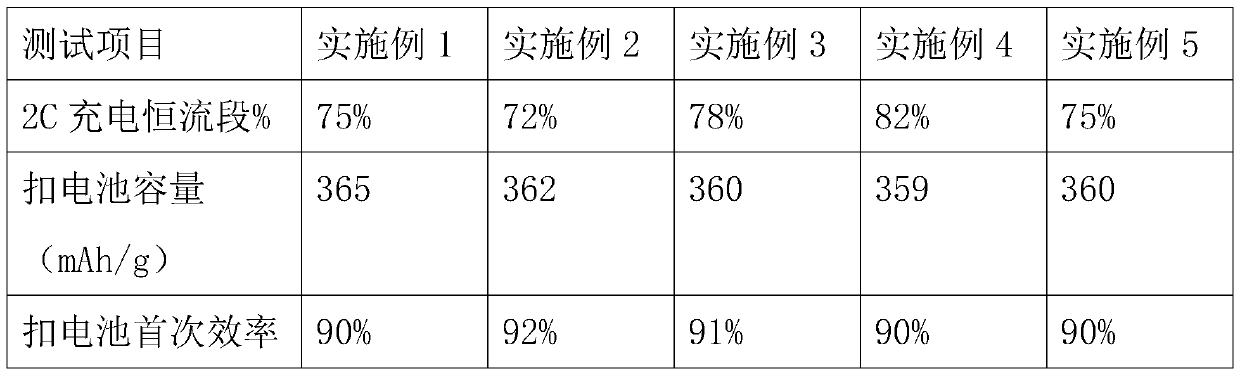

Examples

Embodiment 1

[0031] The preparation method of modified natural graphite for described lithium ion battery comprises the following steps:

[0032] (1) The flaky graphite particles are mixed with modifier particles, and the modifier granules are medium and low temperature asphalt; the mass percent of the modifier is 5%; the flaky graphite particles are 100 mesh sieves ; Flake graphite particles and modifier particles are mixed through a VC mixer; the mixing time is 10 minutes; the speed of the VC mixer is 3r / min;

[0033] (2) Put the mixture obtained in step (1) into a container and then place it in a carbonization furnace. Under a nitrogen atmosphere, raise the temperature in the carbonization furnace to 100° C. at a rate of 3° C. / min;

[0034] (3) The flaky graphite particles obtained in step (2) are sent to the vibration mill, the screw feeding frequency of the vibration mill is 1Hz, the host frequency is 20Hz, and the classification frequency is 10Hz; the sphericity of the flaky graphite...

Embodiment 2

[0036] The preparation method of modified natural graphite for described lithium ion battery comprises the following steps:

[0037] (1) The flaky graphite particles are mixed with modifier particles, and the modifier particles are high-temperature pitches; the modifier mass percent is 25%; the flaky graphite particles are 100 mesh sieves; Shaped graphite particles and modifier particles are mixed through a VC mixer; the mixing time is 20 minutes; the speed of the VC mixer is 100r / min;

[0038] (2) Put the mixture obtained in step (1) into a container and then place it in a carbonization furnace. Under vacuum conditions, raise the temperature in the carbonization furnace to 250° C. at a rate of 3° C. / min;

[0039] (3) the flaky graphite particle of step (2) gained is sent to vibratory mill, and the screw feeding frequency of vibratory mill is 3Hz, and main frame frequency is 50Hz, and classifying frequency is 30Hz; The sphericity of flaky graphite particle is adjusted to 80 %...

Embodiment 3

[0041] The preparation method of modified natural graphite for described lithium ion battery comprises the following steps:

[0042] (1) The flaky graphite particles are mixed with modifier particles, and the modifier particles are cationic emulsified pitch; the modifier mass percent is 30%; the flaky graphite particles are 100 mesh sieves; The flaky graphite particles and the modifier particles are mixed through a VC mixer; the mixing time is 40 minutes; the speed of the VC mixer is 800r / min;

[0043] (2) Put the mixture obtained in step (1) into a container and then place it in a carbonization furnace. Under vacuum conditions, raise the temperature in the carbonization furnace to 250° C. at a rate of 3° C. / min;

[0044] (3) the flaky graphite particle of step (2) gained is sent to vibratory mill, and the screw feeding frequency of vibratory mill is 5Hz, and main machine frequency is 70Hz, and classifying frequency is 50Hz; The sphericity of flaky graphite particle is adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap