h with macroporous structure 2 Catalyst for producing sulfur by s selective oxidation and preparation method thereof

A catalyst, H2S technology, used in physical/chemical process catalysts, chemical instruments and methods, sulfur preparation/purification, etc. Easy sintering, improved reaction effect, strong resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

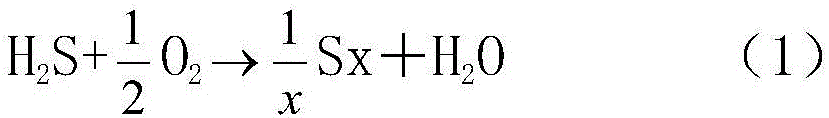

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 1000g of precipitated silica powder (average particle diameter 32μm, specific surface area 126m 2 / g,Na 2 (00.26%), 100g polypropylene ultra-fine powder (average particle diameter 8 μm, get 10g put crucible 600 ℃ of burning and have no visible residue), add in the high-speed mixer that is provided with pressure type atomizing nozzle, seal feed opening , turn on the mixer to stir, and take the plunger type high-pressure pump as the power, first atomize and spray 1000g polyacrylamide aqueous solution (mass concentration 0.5%), and then spray 400g silica sol (SiO 2 Mass concentration 30%, Na 2 O 0.06%, colloidal particle average diameter 25nm) atomization is sprayed in, after 5min, stop the mixer to stir and then discharge, after being kneaded by a kneader, extrude into strips with an outer diameter of 4mm with a twin-screw extruder, dry at 110°C, and Calcined at ℃ for 3 hours to obtain a silica carrier with a measured lateral compressive strength of 162N / cm and a ...

Embodiment 2

[0049] Weigh 1000g of the same precipitated silica powder as in Example 1, 200g of polystyrene superfine powder (the average particle diameter is 25 μm, take 10g and put it in a crucible and burn it at 600°C without visible residue) and add it to a pressure-type atomizing nozzle In the high-speed mixer, close the feed port, start the mixer to stir, and use the plunger type high-pressure pump as the power, first atomize and spray 800g carboxymethyl cellulose aqueous solution (mass concentration 0.3%), and then let it stand for 5hr. Then 700g of silica sol (SiO 2 Mass concentration 20%, Na 2 O 0.03%, colloidal particle average diameter 10nm) atomization sprays in, after 5min, stops the mixer to stir and then discharges, after being kneaded by the kneader, extrude into strips with an outer diameter of 4mm with a twin-screw extruder, dry at 110°C, and dry at 630 Calcined at ℃ for 3 hours to obtain a silica carrier, the measured lateral pressure strength is 155N / cm, the specific s...

Embodiment 3

[0053] Weigh 1000g of precipitated silica powder identical to that of Example 1, 15g of scallop powder (1250 mesh), 300g of polyethylene superfine powder (average particle diameter of 16 μm, take 10g and put it in a crucible at 600° C. without visible residue) Add in the high-speed mixer that is provided with the pressure-type atomizing nozzle, close feed opening, open the mixer and stir, take plunger type high-pressure pump as power, first 800g α-starch aqueous solution (mass concentration 0.3%, gelatinization temperature 65 ℃) atomized and sprayed in, and then 600g of silica sol (SiO 2 Mass concentration 30%, Na 2 (0.04%, colloid average diameter 15nm) atomization sprays in, stops the mixer to stir after 5min, discharges after standing 5hr, is extruded into the bar of outer diameter 4mm with twin-screw extruder after kneading by kneader, 110 ℃ drying, calcination at 600 ℃ for 3 hours to obtain a silica carrier with a measured lateral compressive strength of 165N / cm and a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com