Preparation method of ethyl acetate

A technology of ethyl acetate and silicotungstic acid, which is applied in the field of preparation of ethyl acetate, can solve the problems of unfavorable internal diffusion of heteropolyacids, low catalyst activity, and low yield of ethyl acetate, achieving good selectivity and high activity , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Formed SiO 2 Immersed in 0.01 mol / L Na 2 CO 3 In the solution, the impregnation temperature is 40°C, the impregnation time is 16 hours, and then the impregnated SiO 2 Filter, wash with water until neutral, and dry for later use. Take the Keggin structure silicotungstic acid H 3 SiW1 2 o 40 · x H 2 O20 g was dissolved in 10 ml deionized water. Get the SiO that the above-mentioned alkali handles standby 2 20 grams mixed with the above silicotungstic acid solution, deionized water and SiO 2 The liquid-solid ratio is 0.5 ml / g. In a rotary evaporator, the immersion temperature is 60°C, and the immersion is continuously rotated and immersed for 24 hours; then it is taken out and dried under nitrogen flow for 6 hours at a drying temperature of 120°C; and then under nitrogen flow, 300°C 50 wt% silicotungstic acid / SiO was prepared by firing for 3 hours 2 agent.

[0022] The esterification reaction was carried out using the prepared catalyst. The catalyst was added in...

Embodiment 2~5

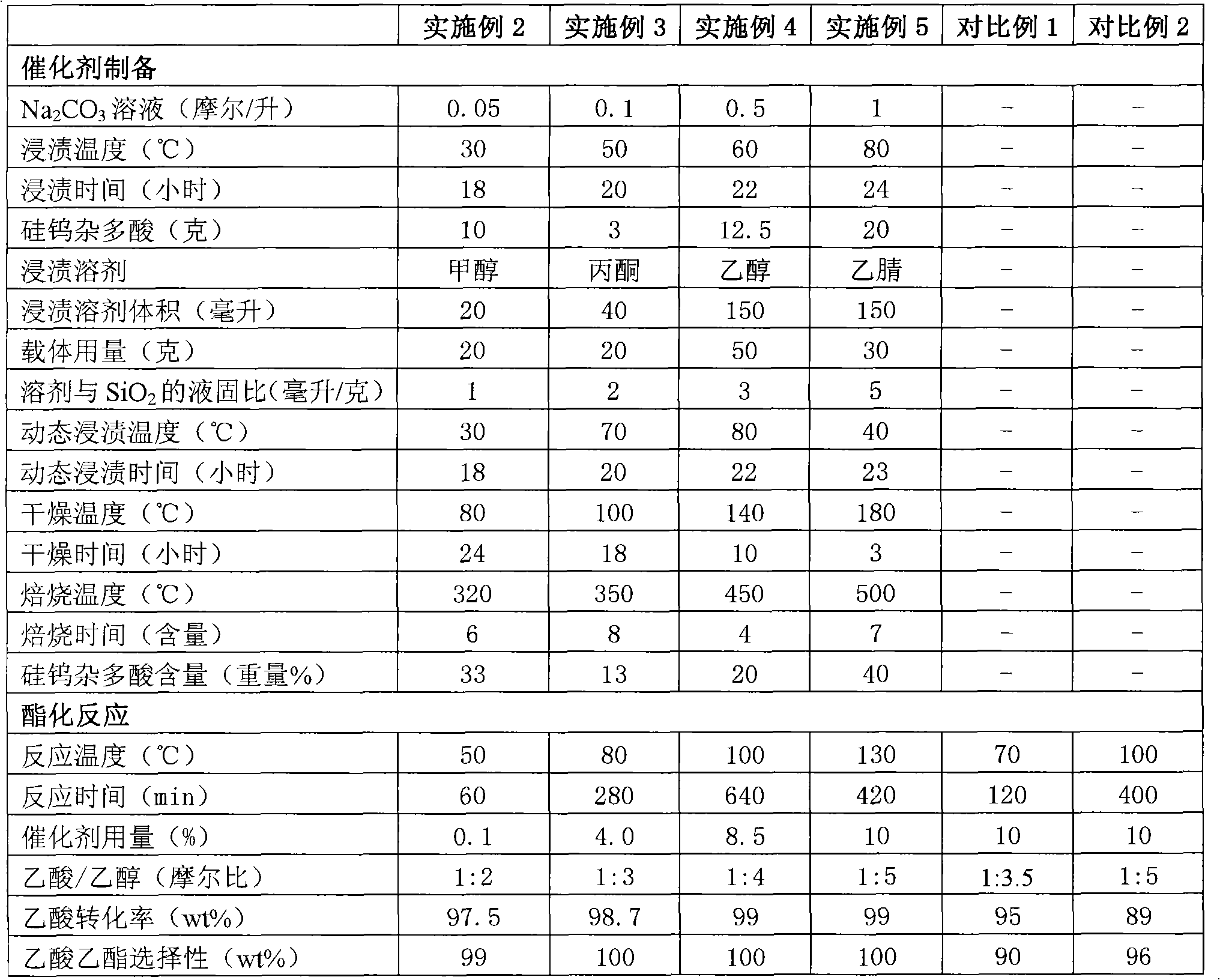

[0024] The catalyst was prepared with [Example 1], and the prepared catalyst was used to prepare ethyl acetate. See Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com