Composite floor slab for steel structural building

A technology for laminated floors and buildings, applied to floors, buildings, building components, etc., can solve problems such as inability to cooperate to increase sweating, and achieve the effects of increasing service life, reducing friction, and good bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

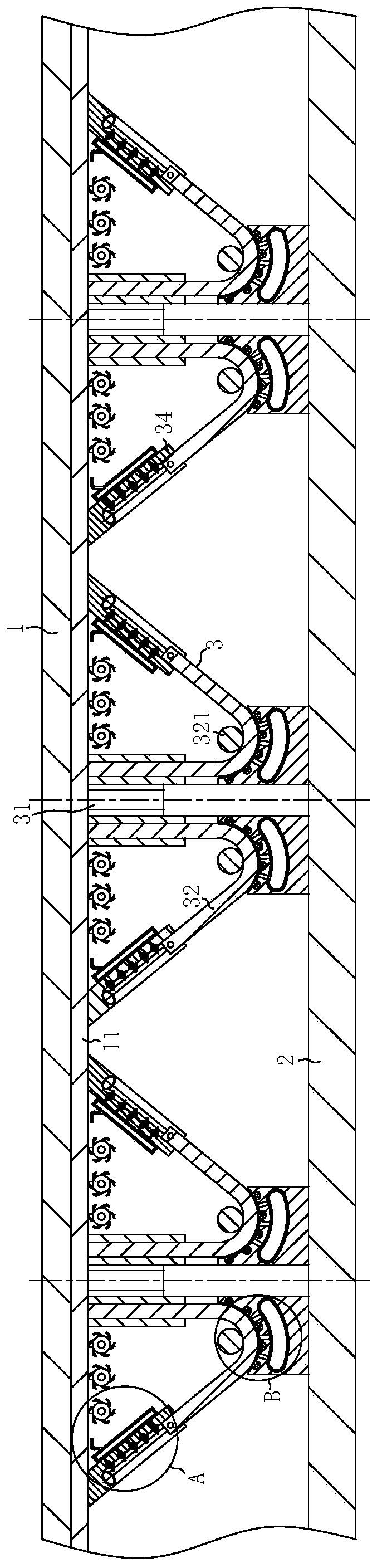

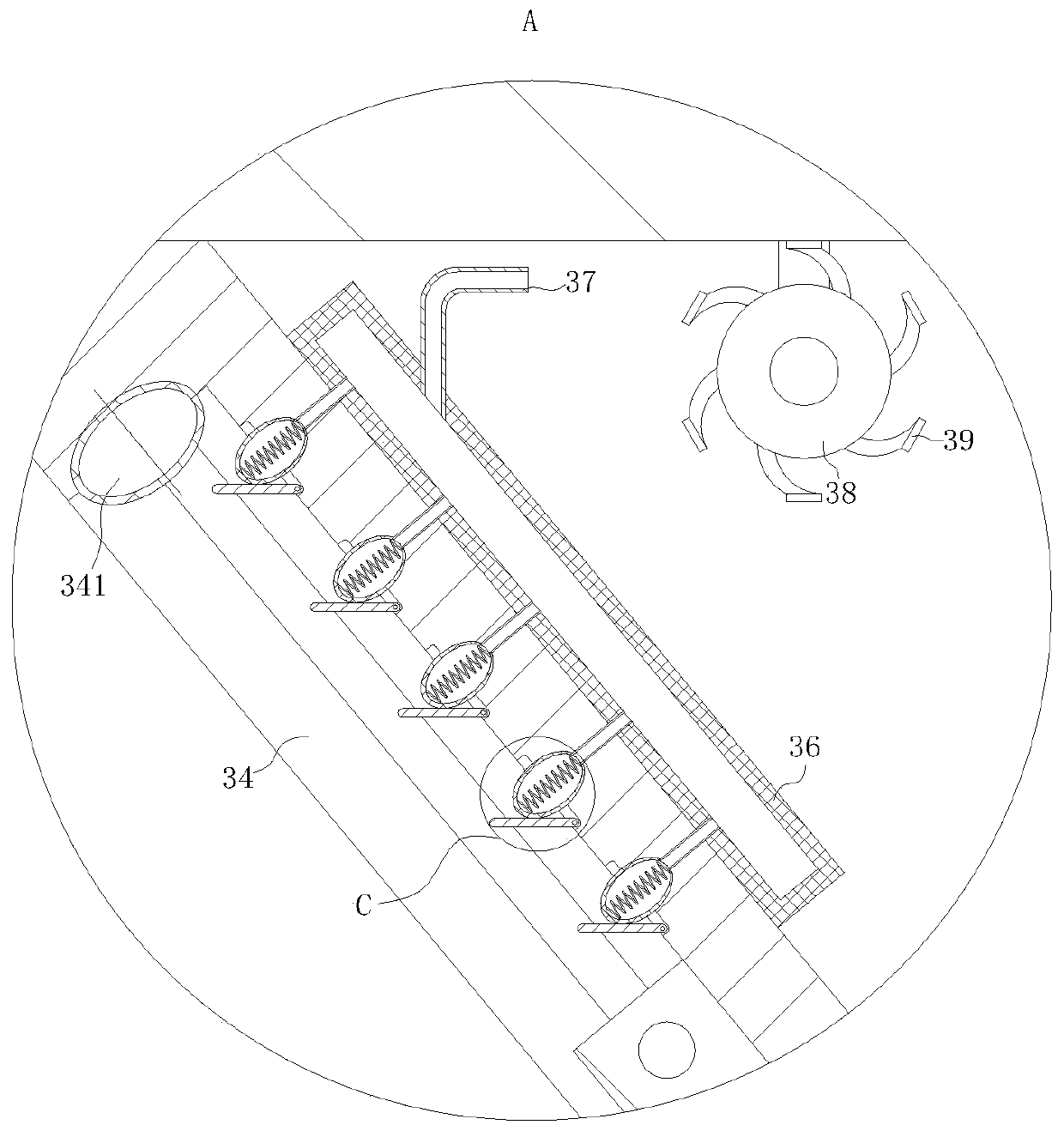

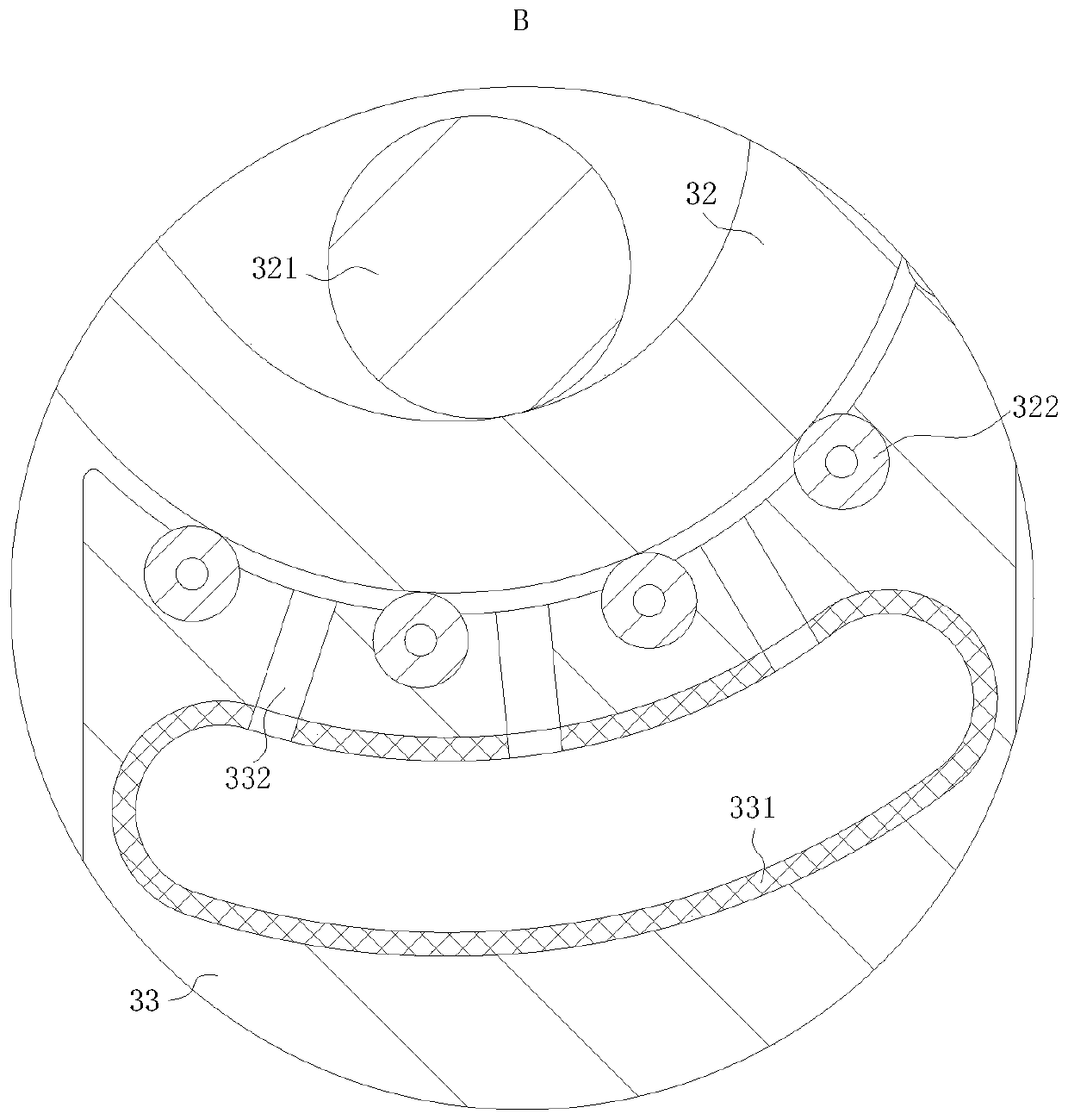

[0019] use Figure 1-Figure 4 A laminated floor slab for a steel structure building according to an embodiment of the present invention will be described as follows.

[0020] like Figure 1-Figure 4As shown, a laminated floor slab for a steel structure building according to the present invention includes an upper steel plate 1, a lower steel plate 2 and a heat generating mechanism 3; the lower surface of the upper steel plate 1 is fixedly connected with a friction plate 11, and the lower surface of the upper steel plate 1 A lower steel plate 2 is provided on the side; a heat generating mechanism 3 is uniformly arranged between the upper steel plate 1 and the lower steel plate 2; the heat generating mechanism 3 includes an elastic telescopic rod 31, a flexible metal plate 32, a guide seat 33, and a connecting plate 34 , No. 1 air bag 35, gas gathering chamber 36, injection pipe 37, rotating wheel 38 and friction block 39; Both sides of the rod 31 are symmetrically provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com