Design Method of Centrifugal Wind Wheel without Volute

A technology of centrifugal wind wheel and design method, which is applied in computer-aided design, calculation, mechanical equipment, etc., can solve problems such as uneven distribution and self-loss, and achieve the effects of reducing noise, eliminating self-loss, and eliminating self-loss areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

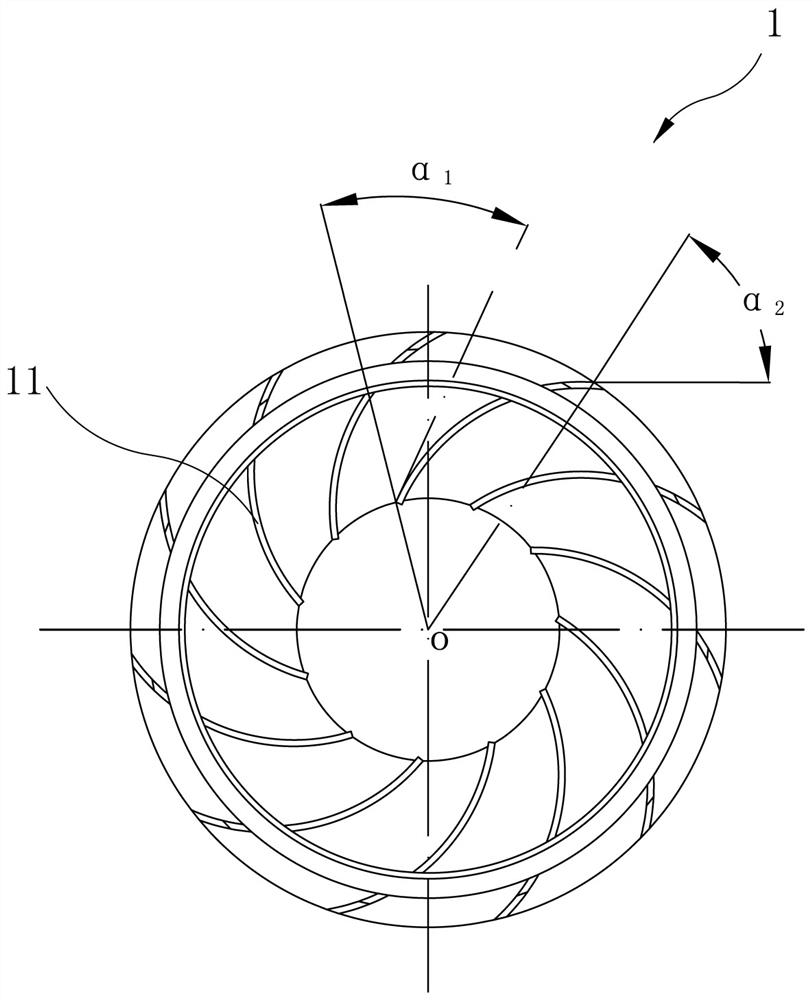

[0029] Such as Figure 2-Figure 4 As shown, the present invention is a design method of a volute-less centrifugal wind rotor, including the outer diameter design of the wind rotor 1 and the blade shape design of the wind rotor blade (referred to as: wind blade) 11 .

[0030] The outer diameter design of described wind wheel 1 comprises the following steps:

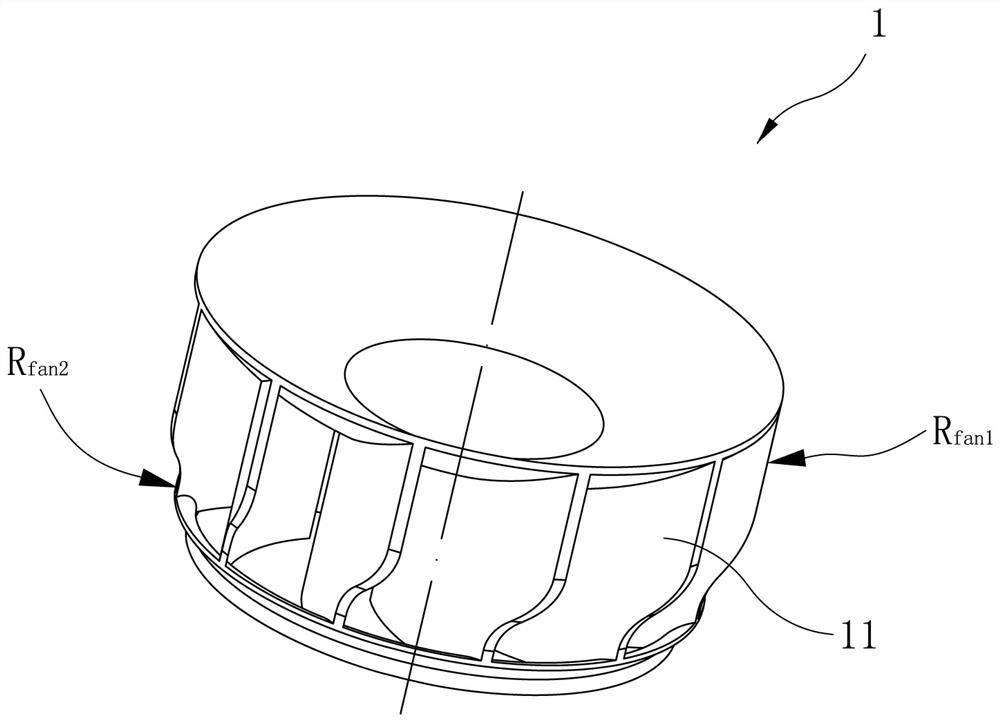

[0031] (1) Calculate the primary outer diameter of the wind rotor 1: R fan 1 = δ*Rad; where: δ is a dimensionless coefficient, 0.72figure 1 shown), R fan 1 is the primary outer diameter of the wind wheel 1;

[0032] (2) Calculate the secondary outer diameter of the wind rotor 1: R fan 2 = ξ*R fan 1; where: R fan 1 is the primary outer diameter of the wind rotor 1, ξ is the dimensionless coefficient, 0.89 image 3 shown.

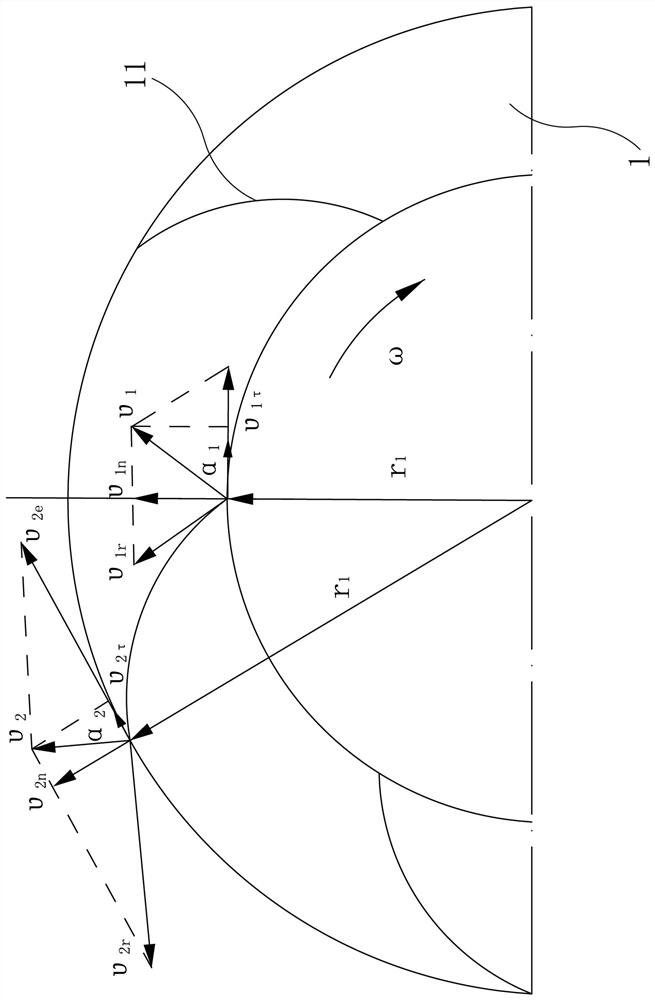

[0033] The airfoil design of described wind rotor blade 11 comprises the following steps:

[0034]

[0035] In the formula: P is the power of the wind wheel 1, ω is the angular velocity of the wind wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com