Rotating key ratchet clutching mechanism for coaxial transmission

A technology of clutch mechanism and transmission, which is applied in the direction of mutually meshing clutches, clutches, mechanical drive clutches, etc., can solve the problems of complex structure and operation, large volume, etc., and achieve the goal of compact structure, simplified complex structure, and simplified shifting operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

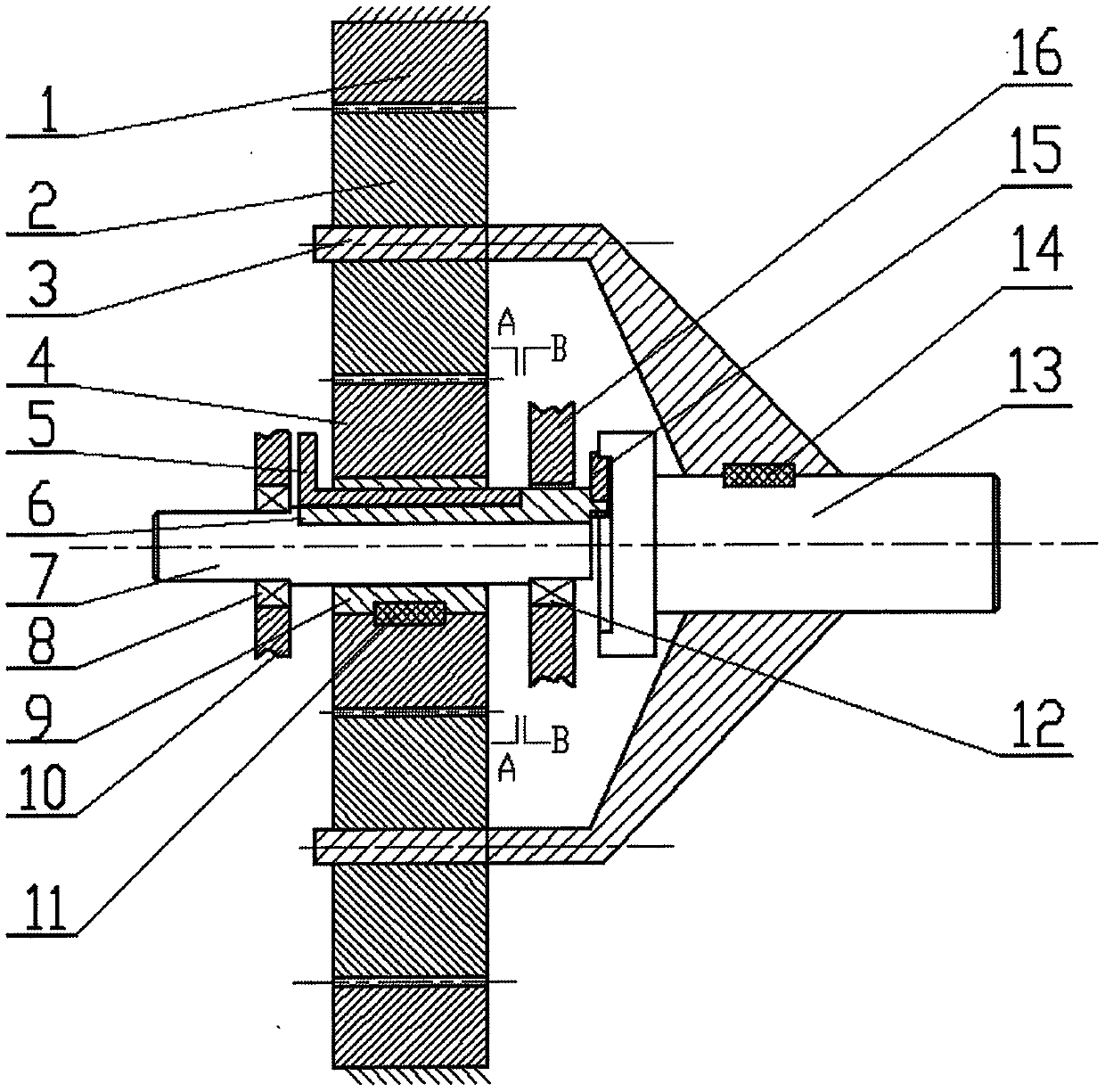

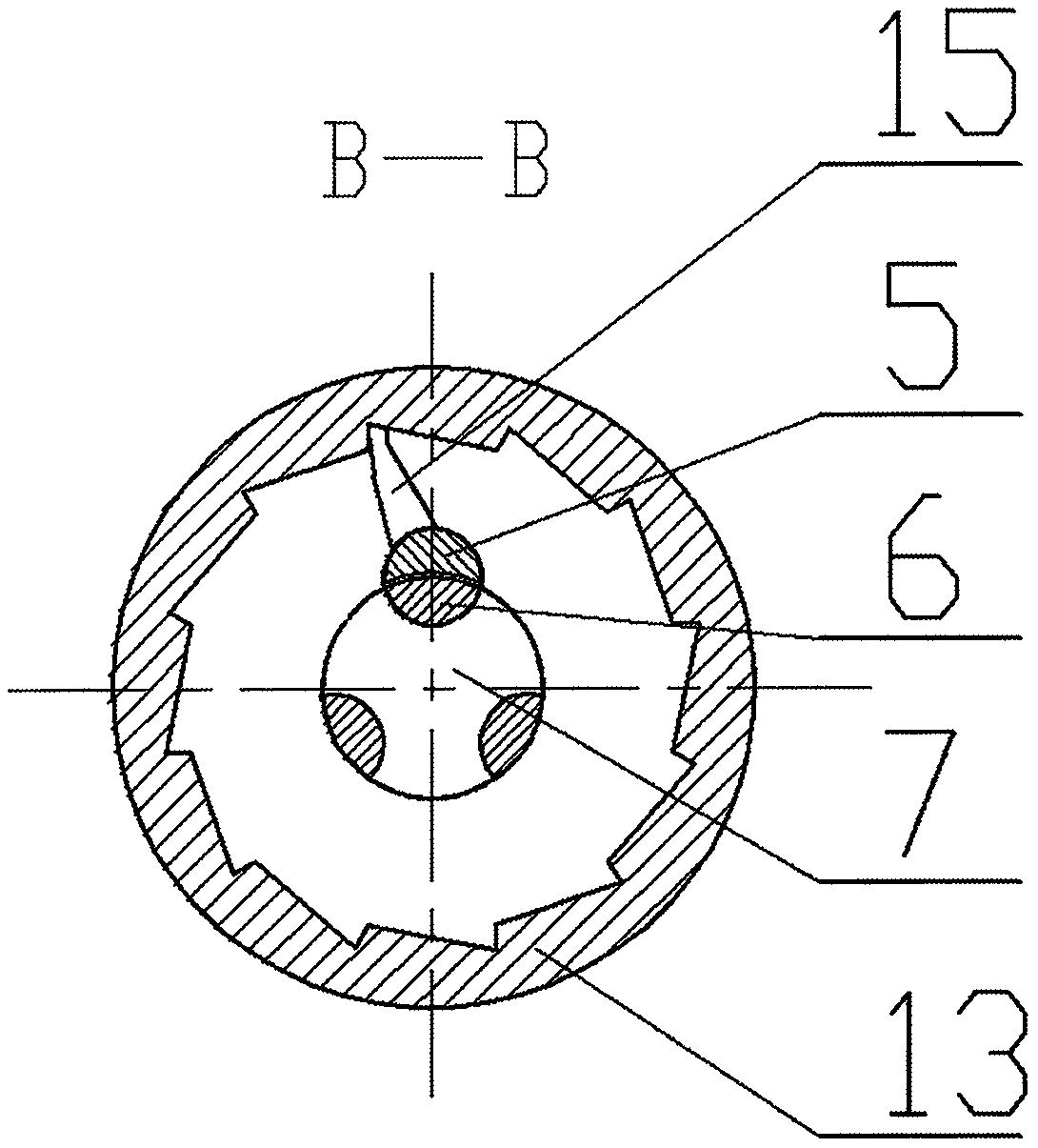

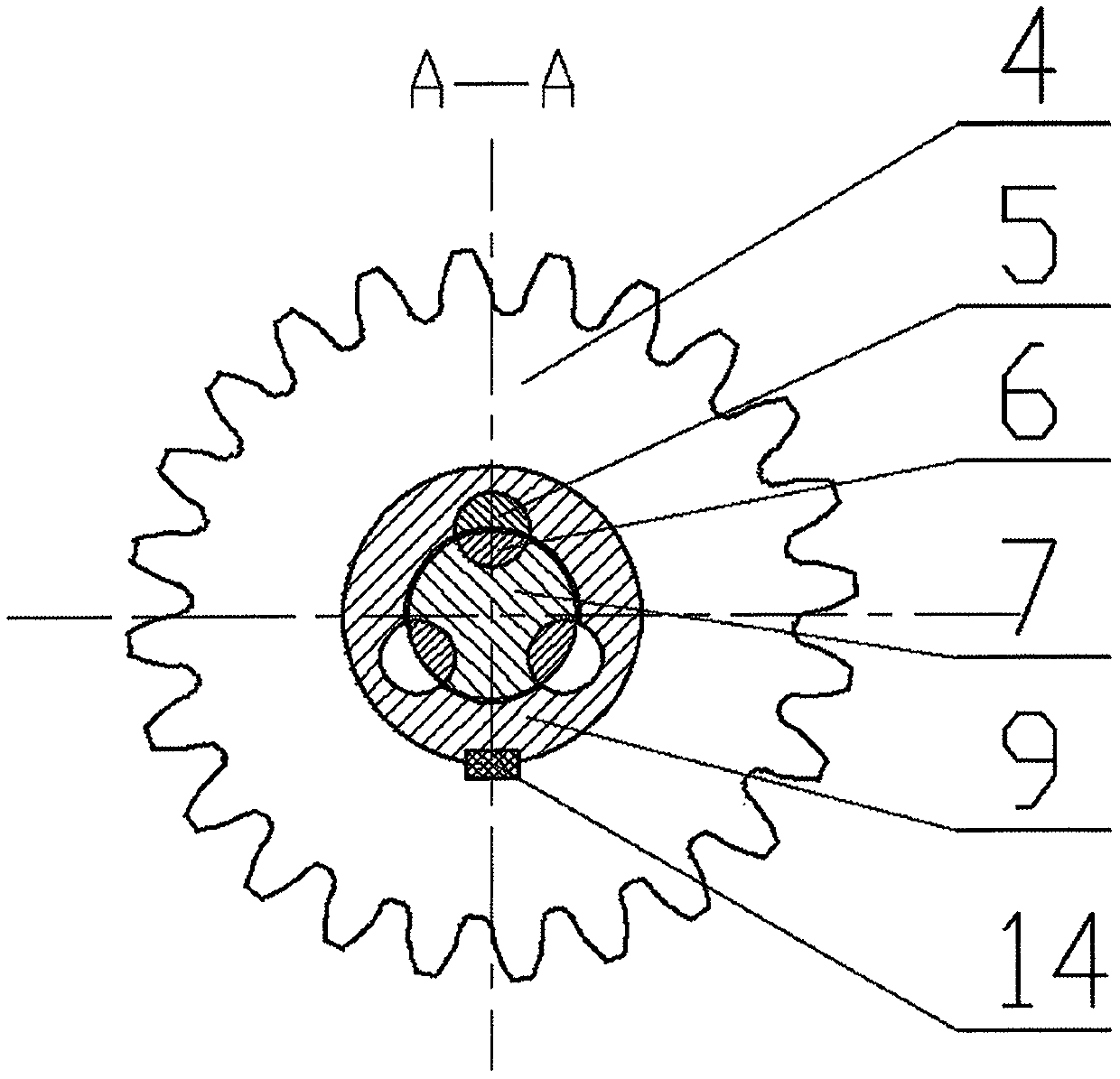

[0012] The principle of the rotary key ratchet clutch mechanism is as follows: figure 1 shown. Taking the planetary gear reducer as an example, the motion mechanism connects the drive shaft (7) with the sun gear (4) in the planetary gear reducer through a rotary key clutch mechanism. The rotating key clutch mechanism is made up of working rotating key (5), matching key (6) and axle sleeve (9). Axle sleeve (9) is connected with sun gear (4) by common flat key (11), can drive sun gear (4) to rotate by axle sleeve (9). The working key (5) is installed in the semicircular keyway on the inner surface of the shaft sleeve (9), the matching key (6) is installed in the semicircular keyway on the outer surface of the drive shaft (7), and the shaft sleeve (9) is sleeved on the On the driving shaft (7), when the semicircular groove of the bushing (9) and the semicircular groove of the driving shaft (7) meet at a certain angle, a circular keyway can be formed. In the circular keyway, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com