Mechanical vehicle transmission shaft retarder

A transmission shaft and mechanical technology, applied in the field of mechanical vehicle transmission shaft retarder, can solve the problems of increasing transmission system load, energy waste, and maintenance difficulties, so as to ensure stability and reliability, improve safety performance, Guarantee the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

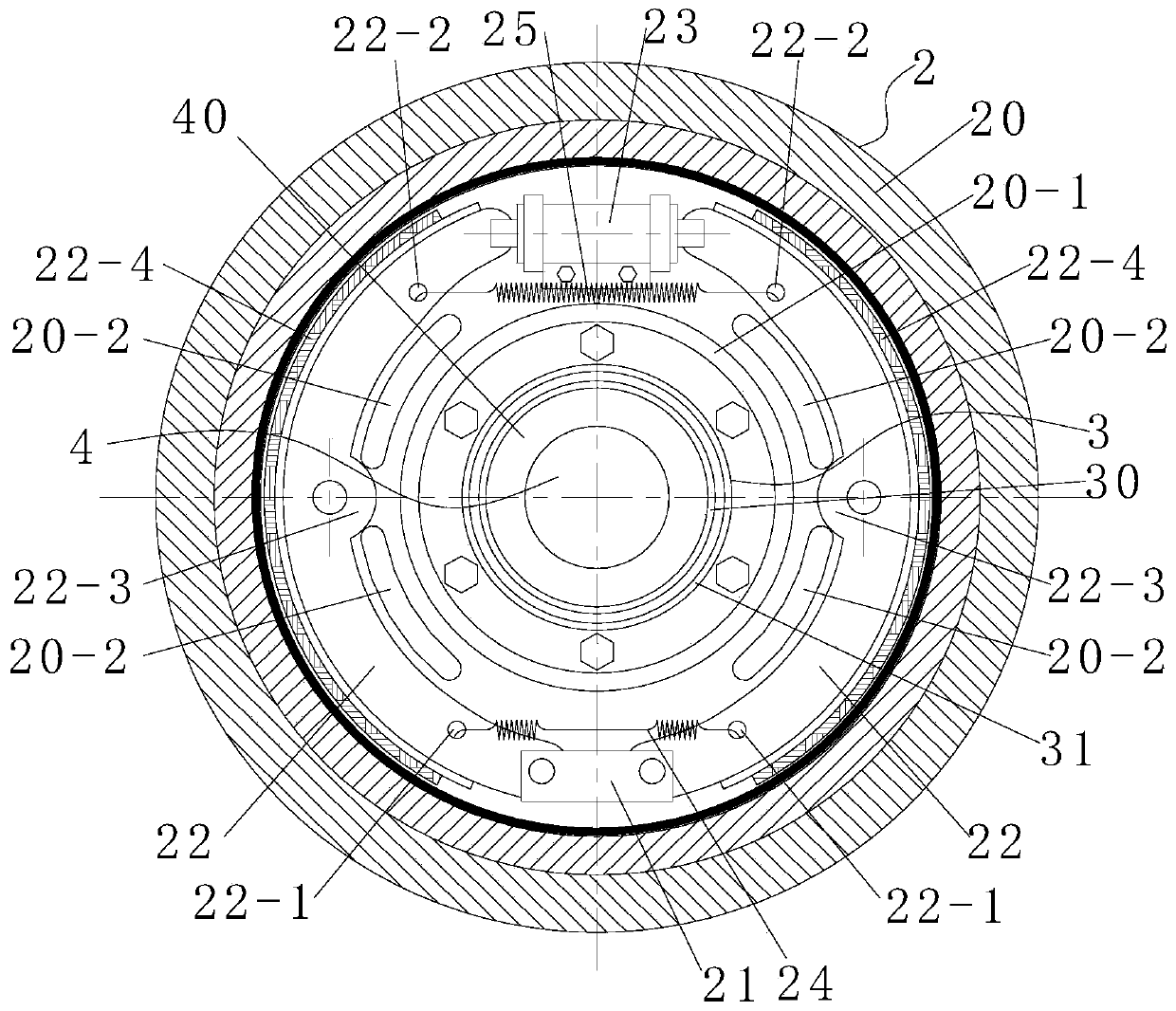

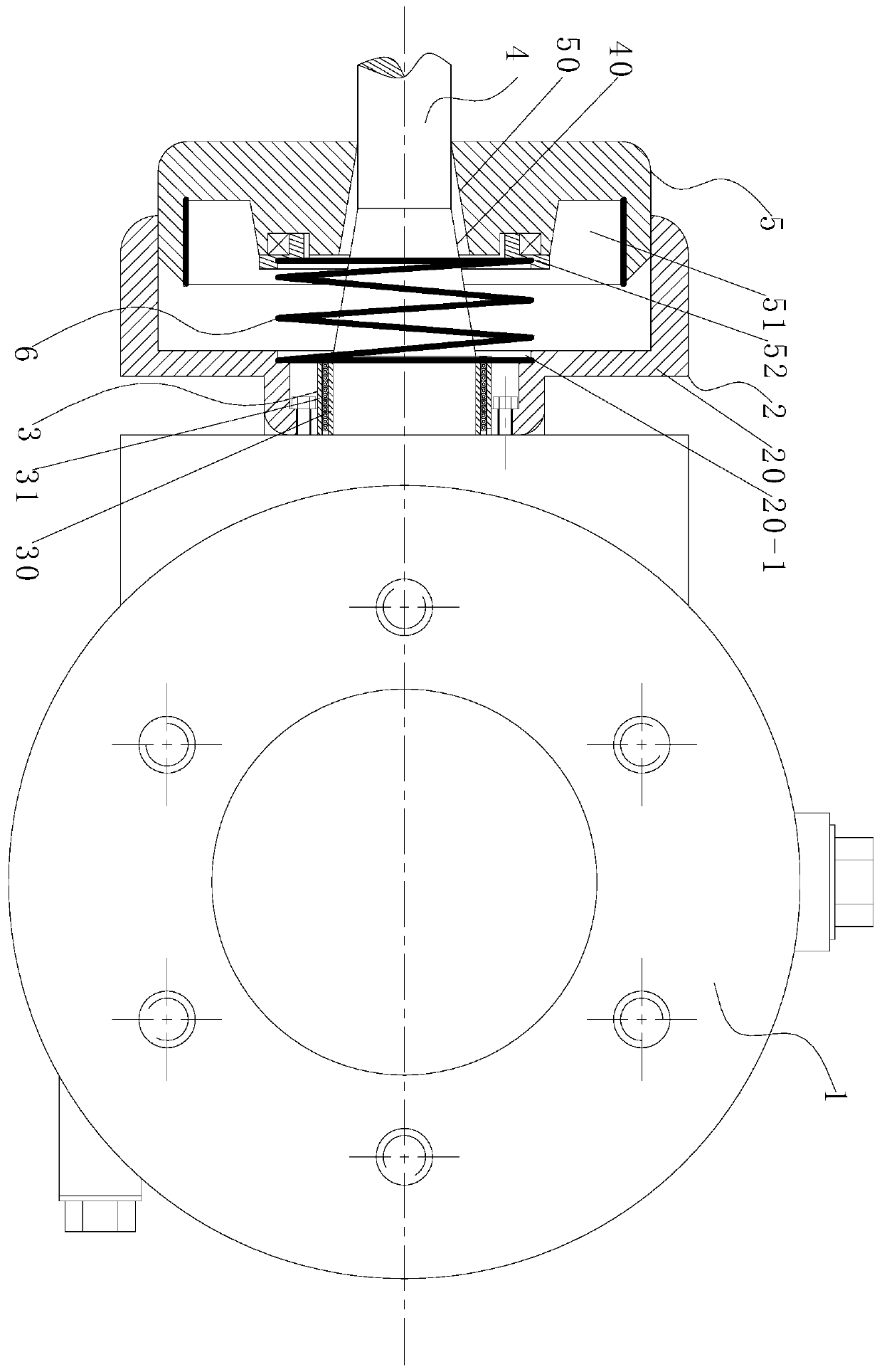

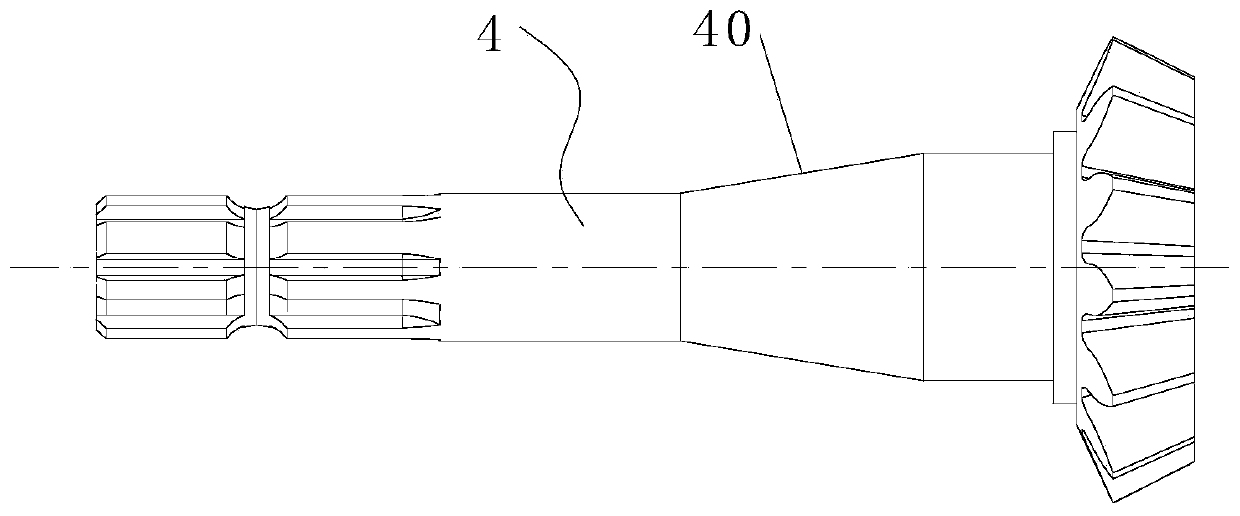

[0043] For the mechanical vehicle transmission shaft retarder, the threshold value written in the controller is set to 80km / h, and the vehicle speed sensor transmits the vehicle speed information to the controller in real time, and the controller compares the transmitted vehicle speed information with the threshold value of 80km / h. When the vehicle speed exceeds 80km / h, the controller controls the electromagnetic relay and the electromagnetic valve to open at the same time. At this time, the spirally wound wire in the electromagnetic tube 3 is energized to generate an electromagnetic field, and the brake wheel cylinder 23 rodless cavity enters oil. Next, the turntable 5 further compresses the compression spring 6 through the spring seat 52, and then the turntable 5 overcomes the elastic force of the compression spring 6 and moves toward the brake housing 20 until the conical hole 50 provided in the center of the turntable 5 and the conical hole 50 provided on the outer wall of t...

Embodiment 2

[0048] On the basis of Embodiment 1, when the speed of the vehicle is low and the retarder does not need to work, the spirally wound wire in the electromagnetic tube 3 is not energized, and then the turntable 5 is moved away under the action of the elastic restoring force of the compression spring 6. One side of the brake housing 20 moves, so that the conical hole 50 provided in the center of the turntable 5 and the conical surface 40 provided on the outer wall of the transmission shaft 4 are in a non-contact state, so that the transmission shaft 4 normally drives the rear axle of the car to work or when the vehicle speed is low. , the retarder does not work, which avoids the energy consumption problem caused by the rotor part always rotating with the high-speed transmission shaft, and reduces the noise and vibration of the transmission system during normal driving.

Embodiment 3

[0050] On the basis of Embodiment 1, the brake housing 20 is provided with an annular sinking platform 20-1, the inner end surface of the turntable 5 is provided with a spring seat 52 through rolling bearing rotation, and one end of the compression spring 6 is clamped with the annular sinking platform 20-1. Limit, the other end is clamped with the spring seat 52 to ensure that the compression spring 6 will not be subjected to the torsional force brought by the rotation of the turntable 5 when the turntable 5 rotates synchronously with the transmission shaft 4, ensuring the normal working form of the compression spring 6 .

[0051] The brake housing 20 is evenly provided with cooling holes 20-2, and a gap is provided between the brake housing 20 and the differential housing 1, which is beneficial to the friction and friction lining between the inner conical surface 40 and the conical hole 50. Dissipation of the heat generated by the friction between the sheet 22-4 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com