Metal rotary kiln cylinder wall temperature detection device

A temperature detection device and rotary kiln technology, applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problems of inaccurate detection temperature, obstruction of dust measurement path, etc., achieve convenient installation, good operation effect, and avoid pollution The effect of the material in the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

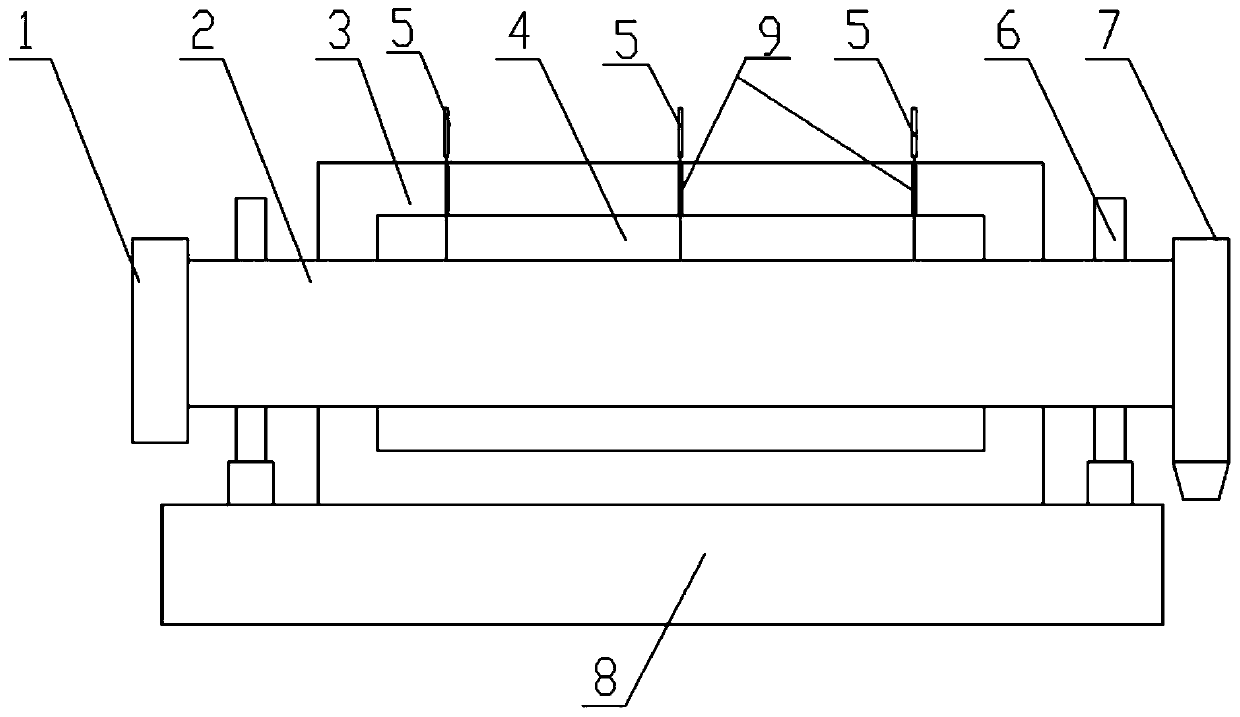

[0020] Metal rotary kiln wall temperature detection device includes:

[0021] Base 8, the base 8 is provided with a heat preservation cover 3, the inside of the heat preservation cover 3 is hollow to form a heating cavity 4, and the cover wall of the heat preservation cover 3 is provided with a passage hole 9, and the passage hole 9 is provided with a corresponding There are infrared detectors5. The infrared detector 5 can emit and receive infrared rays through the channel hole 9 .

[0022] Drum 2, the interior of the drum 2 is hollow to form a working chamber, the two ends of the drum 2 are respectively the feed end and the discharge end, and the feed end and the discharge end are respectively provided with a feed cover 1 and a discharge end. Cover 7, the drum 2 passes through the heating cavity 4 in the heat preservation cover 3, and the feeding end and the discharging end of the drum 2 are respectively erected on the base 8 through the supporting rim 6.

Embodiment 2

[0024] Metal rotary kiln wall temperature detection device includes:

[0025] Base 8, the base 8 is provided with a heat preservation cover 3, the inside of the heat preservation cover 3 is hollow to form a heating cavity 4, and the cover wall of the heat preservation cover 3 is provided with a passage hole 9, and the passage hole 9 is provided with a corresponding There are infrared detectors5. There are a plurality of passage holes 9, and a plurality of passage holes 9 are distributed along the axial interval of the heat preservation cover 3, and an infrared detector 5 is correspondingly installed outside each passage hole 9; each passage hole 9 Extend along the radial direction of the heat preservation cover 3 . The infrared detector 5 can emit and receive infrared rays through the channel hole 9 .

[0026] Drum 2, the interior of the drum 2 is hollow to form a working chamber, the two ends of the drum 2 are respectively the feed end and the discharge end, and the feed en...

Embodiment 3

[0028] Metal rotary kiln wall temperature detection device includes:

[0029] Base 8, the base 8 is provided with a heat preservation cover 3, the inside of the heat preservation cover 3 is hollow to form a heating cavity 4, and the cover wall of the heat preservation cover 3 is provided with a passage hole 9, and the passage hole 9 is provided with a corresponding There are infrared detectors5. There are a plurality of passage holes 9, and a plurality of passage holes 9 are distributed at intervals along the axial direction of the heat preservation cover 3, and an infrared detector 5 is correspondingly installed outside each passage hole 9, and each infrared detector The output end of 5 is connected to PLC, and the collected temperature information can be transmitted to PLC. Each of the passage holes 9 extends along the radial direction of the heat preservation cover 3 . The infrared detector 5 can emit and receive infrared rays through the channel hole 9 .

[0030] Drum 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com