Device for automatically and synchronously replacing optical filter and optical fiber

An automatic synchronization and filter technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems such as limiting the use function and performance of instruments, occupying internal space, increasing costs, etc., to avoid manual disassembly. Replacement, space saving, quick effect of replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The optical filter and optical fiber automatic synchronous replacement device proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The description in this part is only exemplary and explanatory, and should not be regarded as a limitation on the disclosed technical content of the present invention.

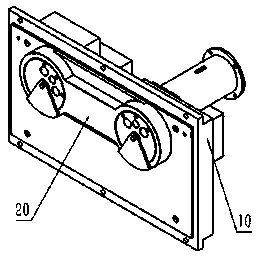

[0021] Such as figure 1 , 2 As shown, the replacement device is composed of two parts: an optical filter replacement mechanism 10 and an optical fiber path replacement mechanism 20 .

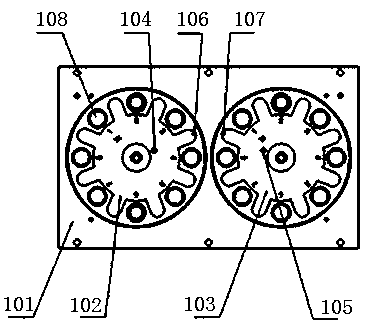

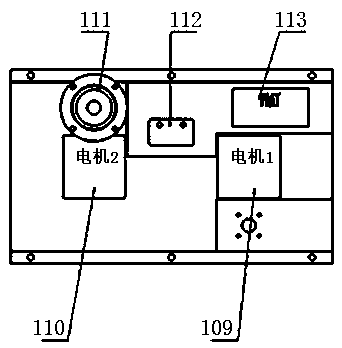

[0022] Such as image 3 , 4 As shown, the filter replacement mechanism 10 includes: a filter replacement mechanism housing 101 for fixing with the instrument body and supporting internal parts, and the filter replacement mechanism housing 101 is fixed with the instrument body by threads ; The emission filter fixing wheel 102 and the exciting filter fixing wheel 103 used for the circular rotation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com