Chemically optimized fiber concrete ring type constrained cracking device

A fiber reinforced concrete, restrained cracking technology, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of difficult crack resistance, large randomness and contingency, and long test period of crack resistance test, so as to improve efficiency and applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

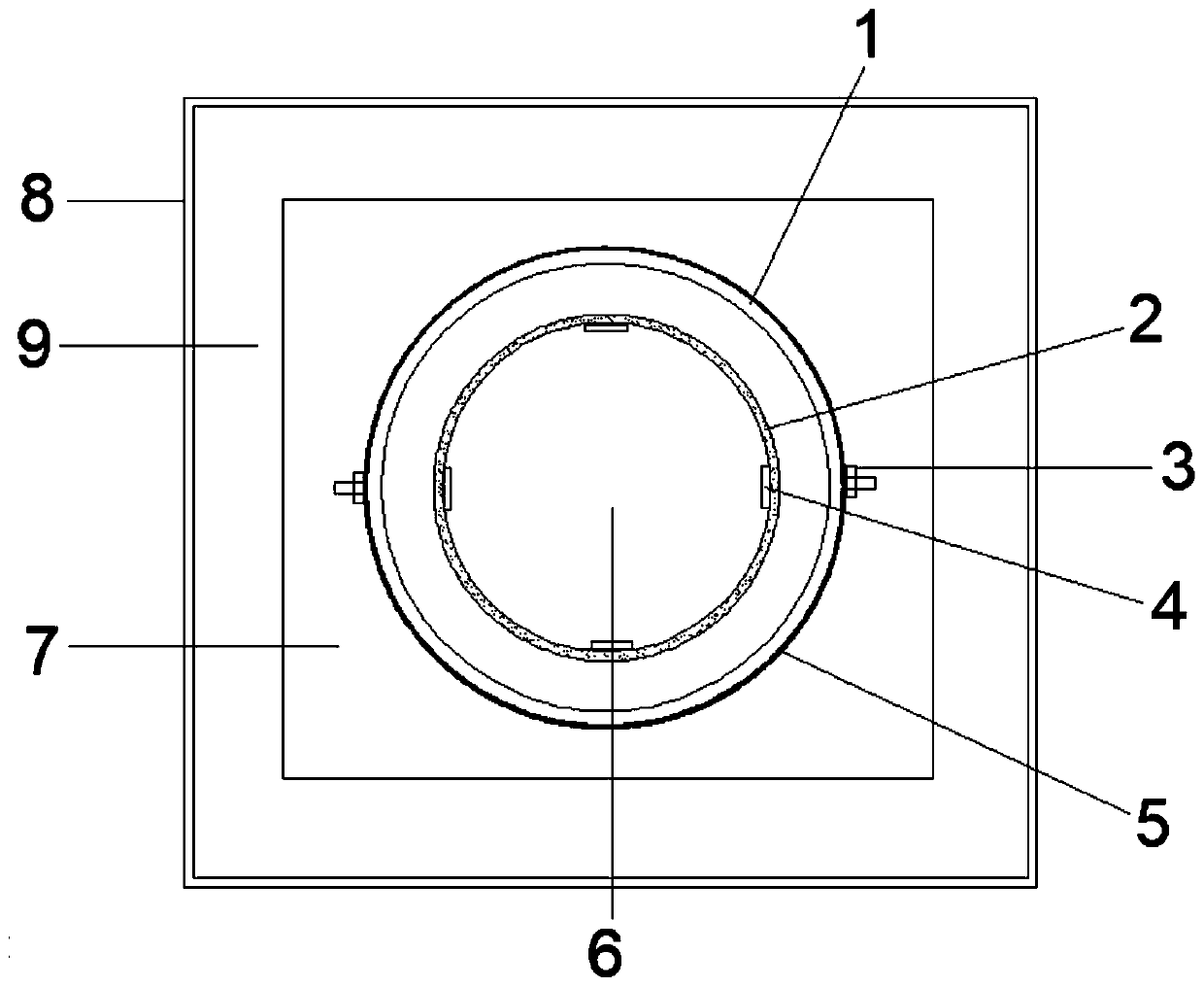

[0023] Such as figure 1 As shown, a chemically optimized fiber reinforced concrete ring restraint cracking device, including ring restraint cracking device 6, OH - The semi-permeable membrane 5, the curing container 8, and the ring-type restraint cracking device are placed on the lower steel bottom plate 7, and the ring-type restraint cracking device and the steel bottom plate are placed in the curing container together. The ring restraint cracking device 6 includes an outer ring 1 and an inner steel ring 2 , a strain gauge 4 and an OH-semipermeable membrane 5 . The inner steel ring is placed in the outer ring, and at the same time, the inner steel ring 2 is quartered with strain gauges 4, and the outer ring 1 is tightly wrapped with OH - Semi-permeable membrane5.

[0024] In this example, fiber reinforced concrete mixed with cellulose fibers was used as the cracking specimen, PO42.5 cement was used, and the content of cellulose fibers was 2%-4% of the total volume, and it w...

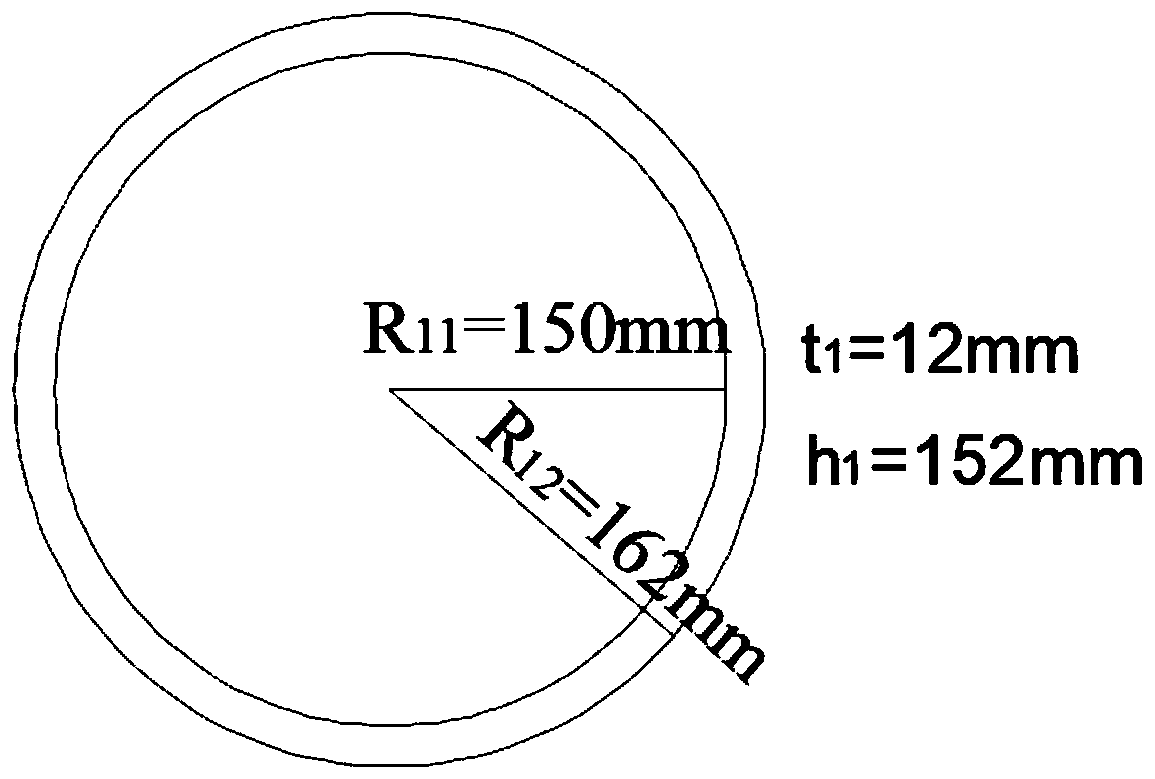

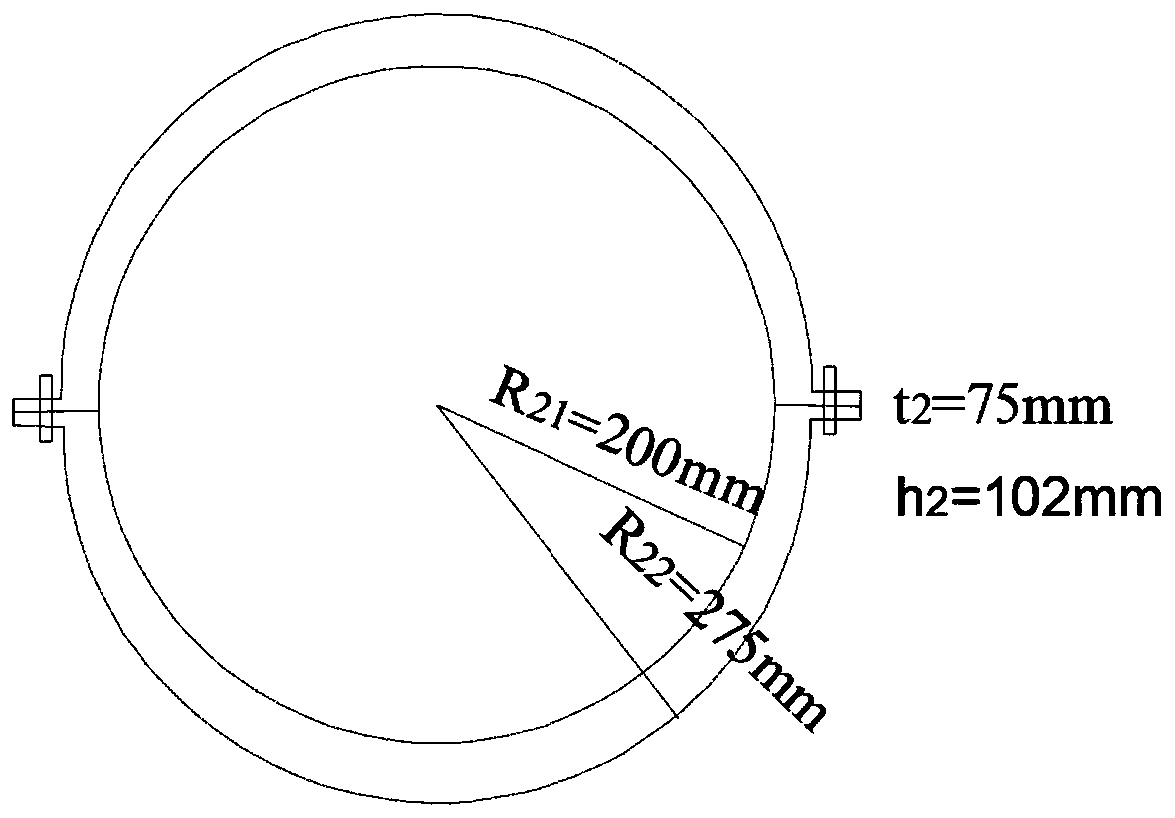

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com