Coiled tubing fracture fault simulation method

A fault simulation and tubing technology, applied in simulators, space navigation condition simulation devices, teaching models, etc., can solve the problems of weak training effect and high training cost, and achieve the effect of strengthening training effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

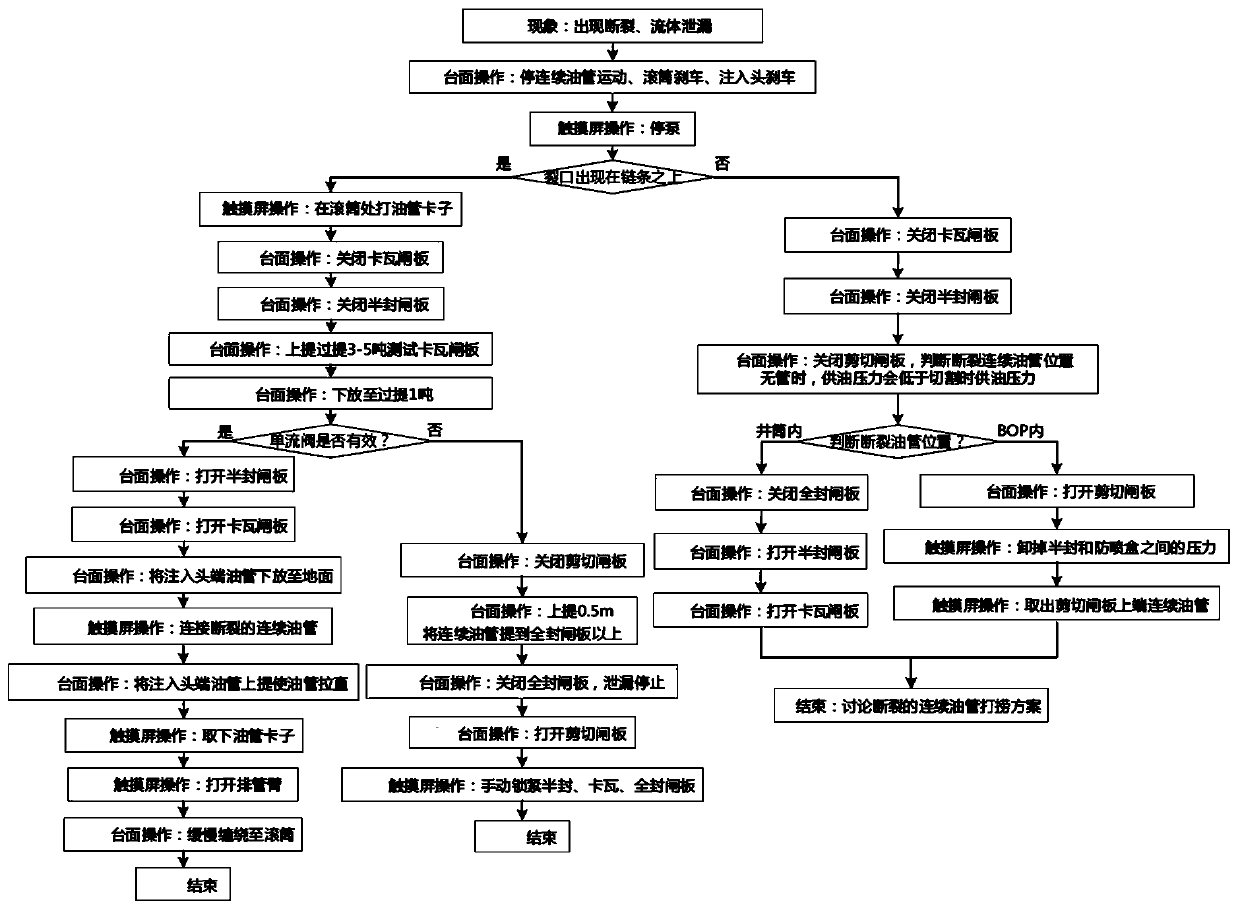

[0023] Coiled tubing rupture failure simulation method, using the coiled tubing simulation system to simulate the coiled tubing rupture phenomenon, through the simulation system console and touch screen for processing operations, including the following steps:

[0024] S1: Stop the coiled tubing, roller brake, and injection head brake through the console, and stop the pump through the touch screen to judge whether the crack is on the chain, if so, go to S2, otherwise, go to S4;

[0025] S2: Use the touch screen to drive the oil pipe clamp at the drum, close the slip gate and half-sealed gate through the console, and lift the 3-5 tons to test the slip gate, and lower it to 1 ton to judge the single flow Whether the valve is effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com