A silk fibroin/polymer-based tubular scaffold with three-dimensional ordered and disordered double network structure and its preparation and use method

A three-dimensional orderly, network-structured technology, applied in medical science, prostheses, tissue regeneration, etc., can solve problems such as difficulty in forming a three-dimensional pore structure and limited ability to induce cell growth, so as to ensure mechanical support and enhance biocompatibility Good performance and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

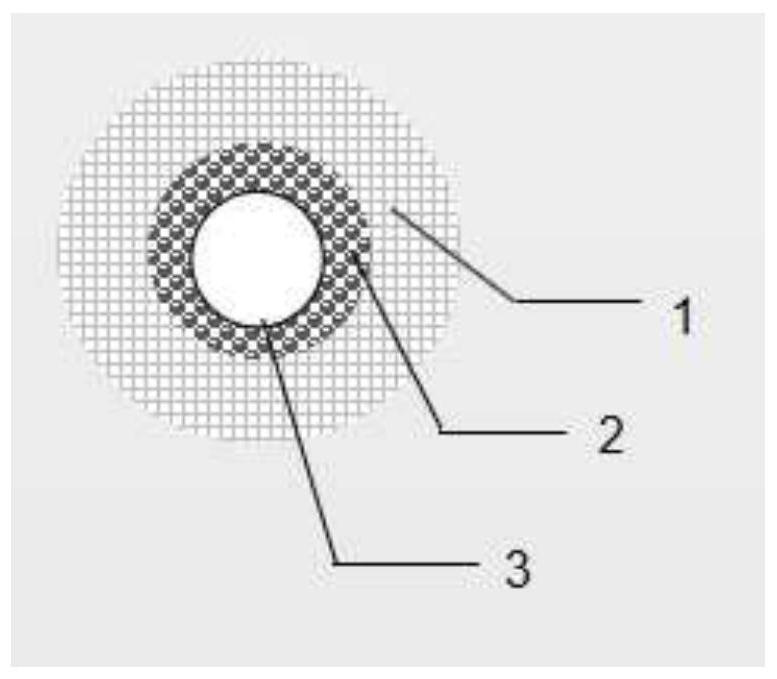

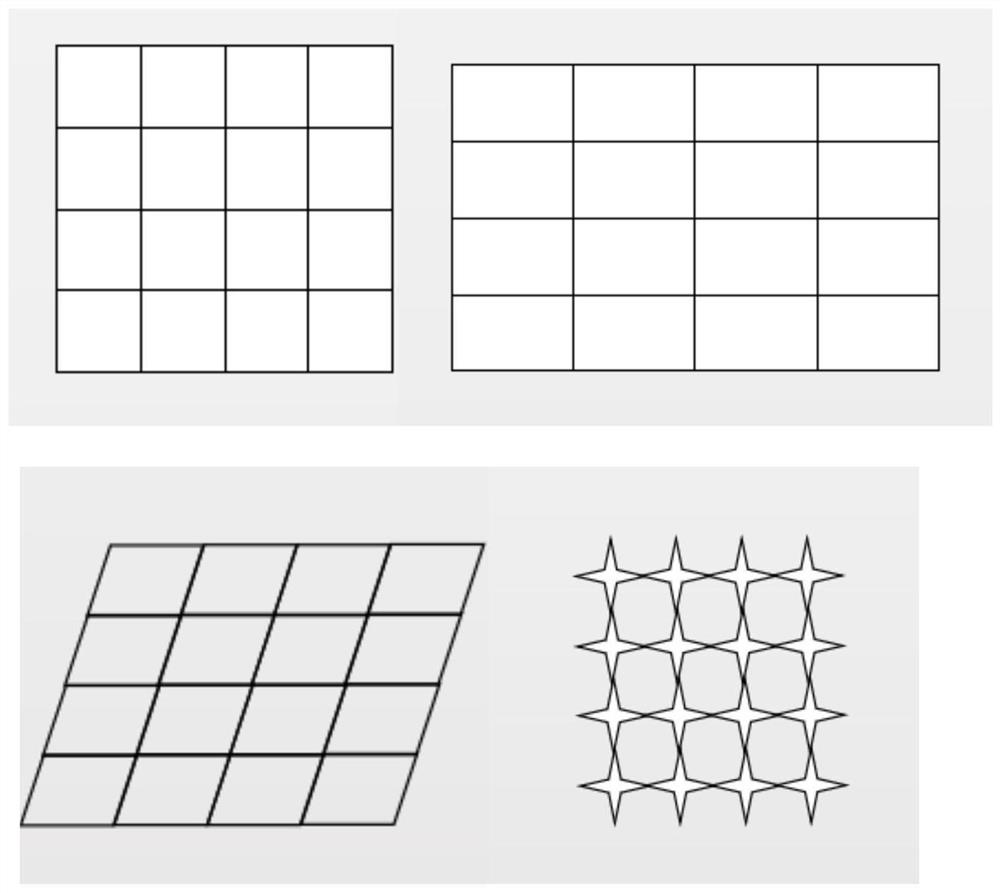

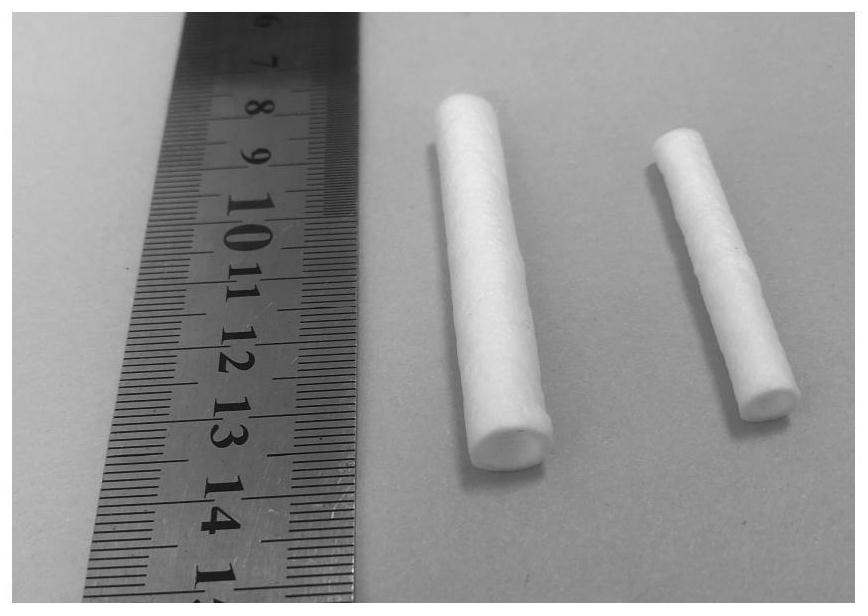

[0034] (1) Add polylactic acid PLA into tetrahydrofuran to fully dissolve to obtain a 5g / L polymer solution, inject the polymer solution into a tubular mold with an inner diameter of 15mm, freeze-dry it quickly at -60°C, and then freeze it at -20°C Vacuum freeze-drying for 2 days and demoulding to obtain a polymer porous inner layer scaffold with a wall thickness of 2 mm, wherein the polymer porous inner layer scaffold contains a honeycomb pore structure with a pore size of 20-200 μm.

[0035] (2) The titanium-nickel shape memory alloy with a diameter of 0.2-0.3mm is used to form a metal mesh with a pore size of 0.8-1.5mm. After the inner support surface is covered with a layer of medical rubber, the polymer porous inner layer bracket is covered with medical rubber. On the surface, a tubular scaffold with a polymer porous inner layer supported by a metal mesh is obtained.

[0036] (3) Add silkworm cocoons to 0.05% Na2CO3 solution, the bath ratio is 1:50, after degumming at 100...

Embodiment 2

[0039] (1) Add polycaprolactone PCL to tetrahydrofuran to fully dissolve to obtain a 10g / L polymer solution, inject the polymer solution into a tubular mold with an inner diameter of 35mm, freeze-dry quickly at -80°C, and then dry it at -30 Vacuum freeze-drying at °C for 4 days, demoulding to obtain a polymer porous inner layer scaffold with a wall thickness of 6 mm, wherein the polymer porous inner layer scaffold contains a honeycomb pore structure with a pore size of 20-200 μm.

[0040] (2) A titanium-nickel shape memory alloy with a diameter of 0.3 mm is used to form a metal mesh with a pore size of 1.5 mm. After the inner support surface is covered with a layer of medical rubber, the polymer porous inner layer bracket is placed on the surface of the medical rubber to obtain a metal mesh containing A polymeric porous inner tubular scaffold supported within a metal mesh.

[0041] (3) Add silkworm cocoons to 0.05% Na2CO3 solution, the bath ratio is 1:50, after degumming at 10...

Embodiment 3

[0044] (1) Add polylactic acid-glycolic acid copolymer PLGA into tetrahydrofuran to fully dissolve to obtain a polymer solution of 8 g / L, inject the polymer solution into a tubular mold with an inner diameter of 20 mm, and freeze-dry it quickly at -70 ° C. Vacuum freeze-drying at -25°C for 3 days, demoulding to obtain a polymer porous inner layer scaffold with a wall thickness of 4 mm, wherein the polymer porous inner layer scaffold contains a honeycomb pore structure with a pore size of 20-200 μm.

[0045] (2) A titanium-nickel shape memory alloy with a diameter of 0.25 mm is used to form a metal mesh with a pore size of 1.2 mm. After the inner support surface is covered with a layer of medical rubber, the polymer porous inner layer bracket is placed on the surface of the medical rubber to obtain a metal mesh containing A polymeric porous inner tubular scaffold supported within a metal mesh.

[0046] (3) Add the raw silk to the 0.05% Na2CO3 solution, the bath ratio is 1:50, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com