Sound wave reinforced fine particle removing device and removing method thereof

A technology for fine particles and particles, which is applied in the field of acoustic wave-enhanced fine particle removal devices, can solve the problems that the agglomeration effect of fine particles is not obvious, and the removal efficiency of fine particles cannot be effectively improved, so as to avoid secondary dust and stabilize the system Long run times for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

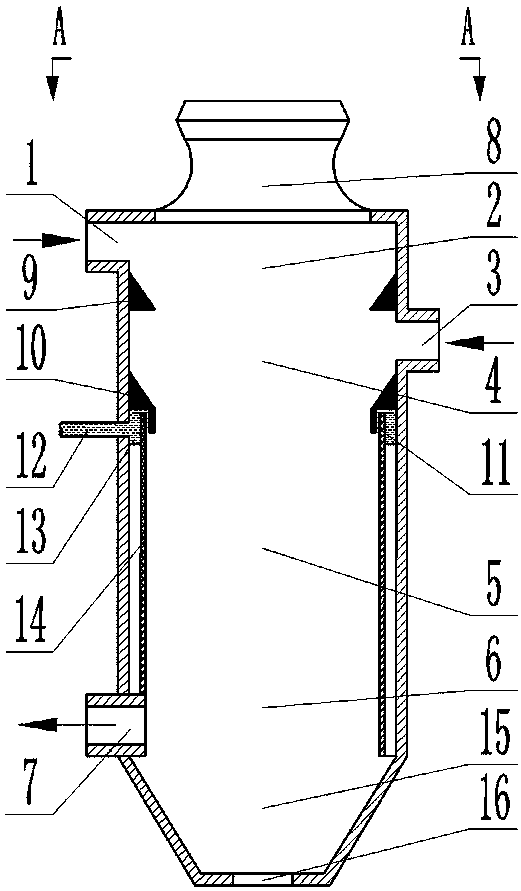

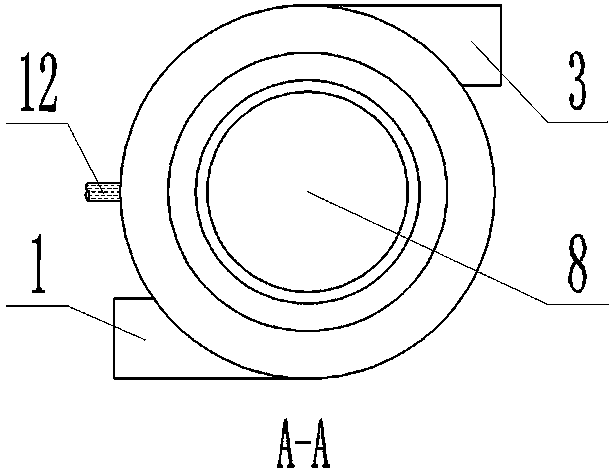

[0030] see Figure 1 to Figure 2 , the sound wave enhanced fine particle removal device in this embodiment includes a pretreatment aerosol particle inlet 1, aerosol turbulence and acoustic wave pretreatment area 2, aerosol particle inlet 3, aerosol turbulence and acoustic wave agglomeration area 4, Aerosol dust collection area 5, inertial sedimentation dust collection area 6, aerosol outlet 7, acoustic wave generator 8, aerosol turbulent flow pretreatment gathering effect ring 9, aerosol turbulent flow gathering effect ring 10, baffle plate 11, water film The dust collection plate is externally connected to a water source access pipeline 12, a water tank 13, a dust collection plate 14, an ash hopper 15 and a slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com