Inclined multi-station integrated shaft workpiece turning automation integrated machine tool

A shaft-type workpiece and multi-station technology, applied in turning equipment, turning equipment, metal processing, etc., can solve the problems of large floor area of machine tools, high cost of machine tool maintenance, and long time, so as to achieve low maintenance cost, The effect of short process changeover distance and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

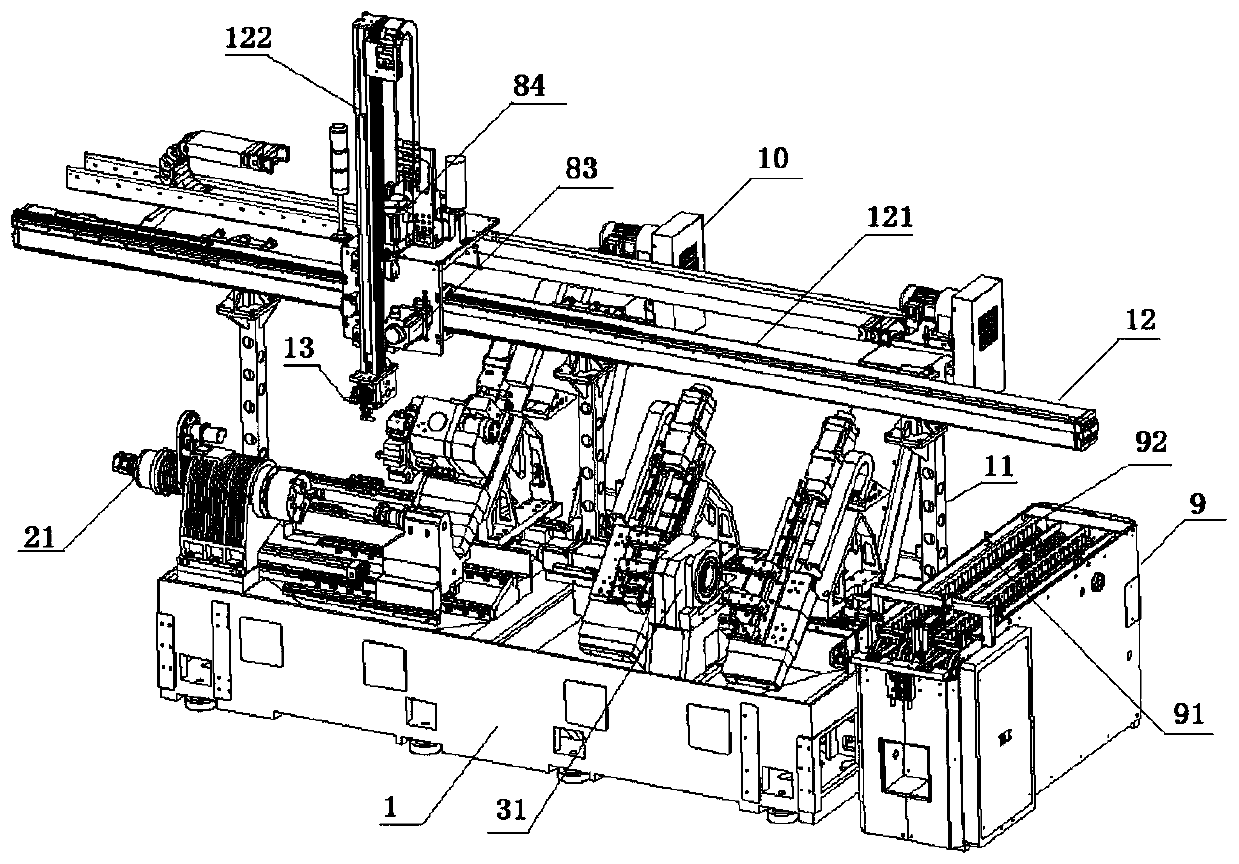

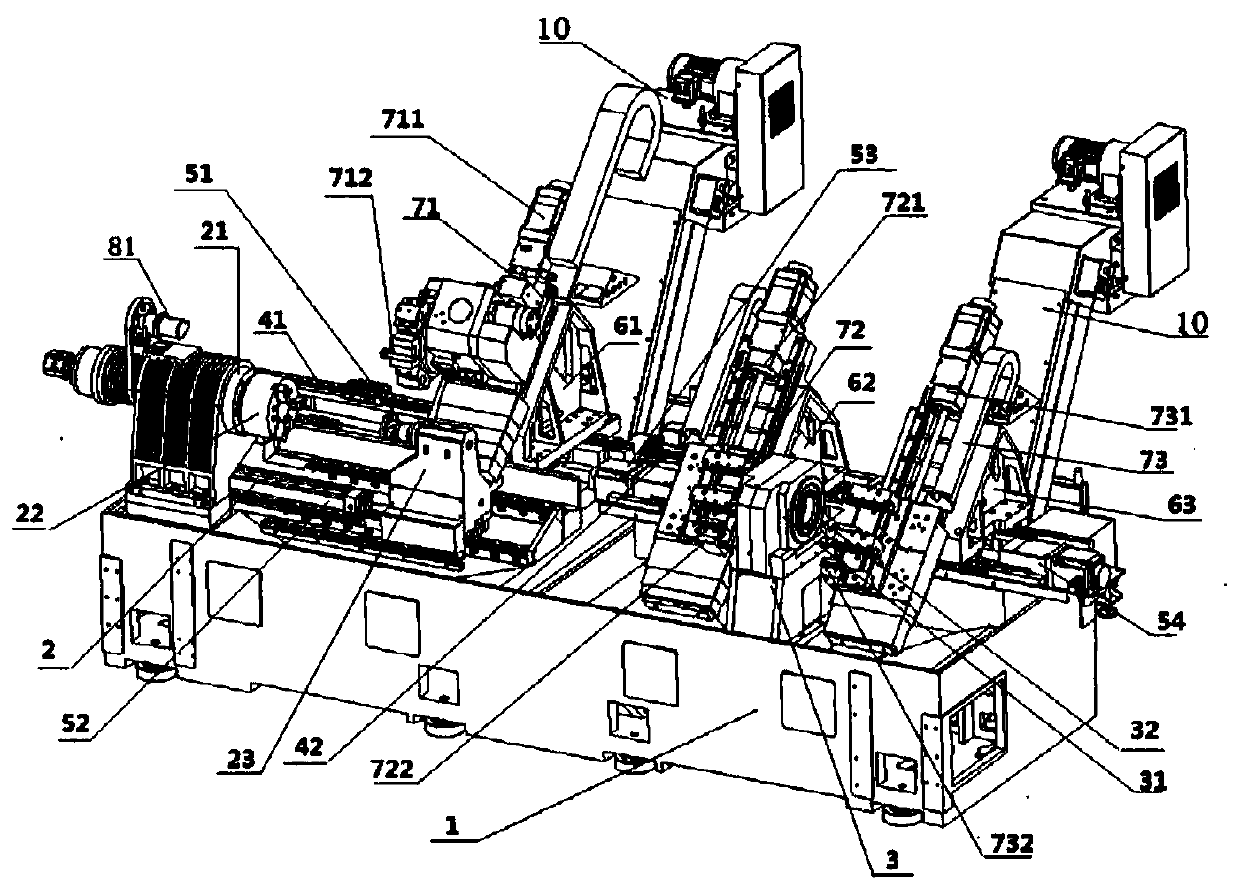

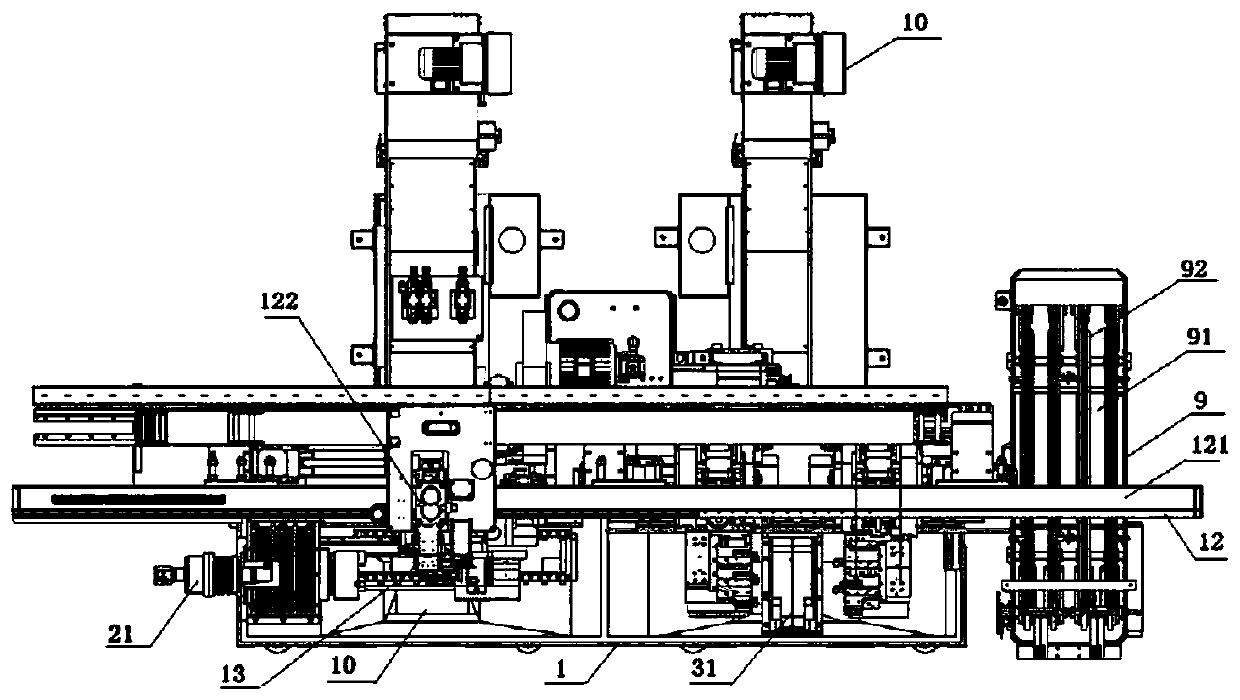

[0020] An inclined multi-station integrated shaft-type workpiece turning automatic integrated machine tool, such as figure 1 , 2 , 3 and 4, including a frame 1, the frame 1 is provided with a lathe station 2 and a double-sided lathe station 3, and the lathe station 2 includes three The main shaft 21 of the claw chuck 22, the first slide rail 41 arranged on the frame 1, the first servo transmission part 51 and the oil cylinder 52 are installed on the first slide rail 41 and driven by the first servo transmission part 51 along the first The first slide saddle 61 that a slide rail 41 moves, the first feed tool 71 installed on the first slide rail 61, the tailstock 23 that is arranged on the first slide rail 41 and is driven by the oil cylinder 52 to move along the first slide rail 41 , the first feed tool 71 is composed of a fourth servo transmission part 711 and a first tool part 712, the main shaft 21 is provided with a first motor 81 that drives the main shaft 21 to rotate; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com