Self-centering and synchronous clamping mechanism

A synchronous clamping and self-centering technology, applied in the direction of the chuck, etc., can solve the problems of the wedge-shaped synchronous clamping mechanism, such as complex structure, inconvenient operation, and inability to realize self-locking, and achieve the effect of compact structure, simple structure and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below through a specific embodiment in conjunction with the accompanying drawings.

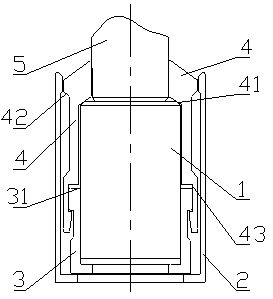

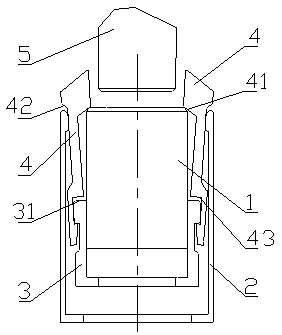

[0010] Such as Figure 1 to Figure 2 As shown, a self-centering synchronous clamping mechanism includes an ejector, a positioning member, a guide, and m claws, wherein m is a natural number, and m≥2; the m claws are along the outer surface of the workpiece Evenly arranged, the claws are provided with step 1 and step 2, ejectors are provided on the inside of the m claws, guides are provided on the outside of the ejectors, and positioning parts are provided on the outside of the m claws pieces.

[0011] In this embodiment, the claw is provided with a groove, and the guide is provided with a protrusion, and the groove and the protrusion adopt a clearance fit; the transition surface of the step 1 includes an inclined surface, a tapered surface, Arc-shaped surface; the transition surface of the step 2 includes an inclined surface, a tapered s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com