Wheel leg type humanoid robot with internal oil flowing

A humanoid and robot-like technology, applied in manipulators, motor vehicles, program-controlled manipulators, etc., can solve problems affecting the flexibility of robot movement, long hose layout, complexity, etc., to avoid shortened motor life and pipeline wear failures The effect of reduction and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

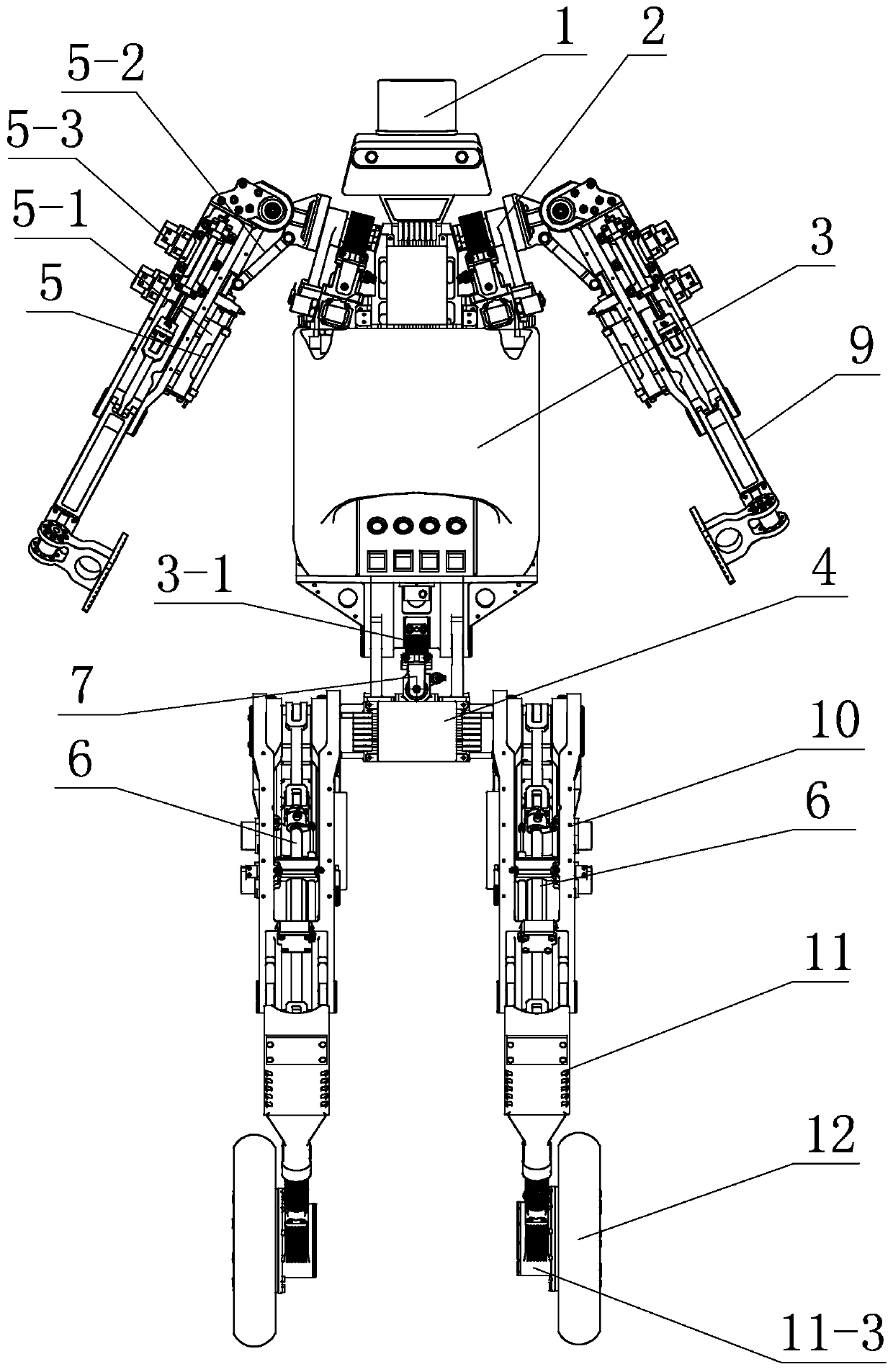

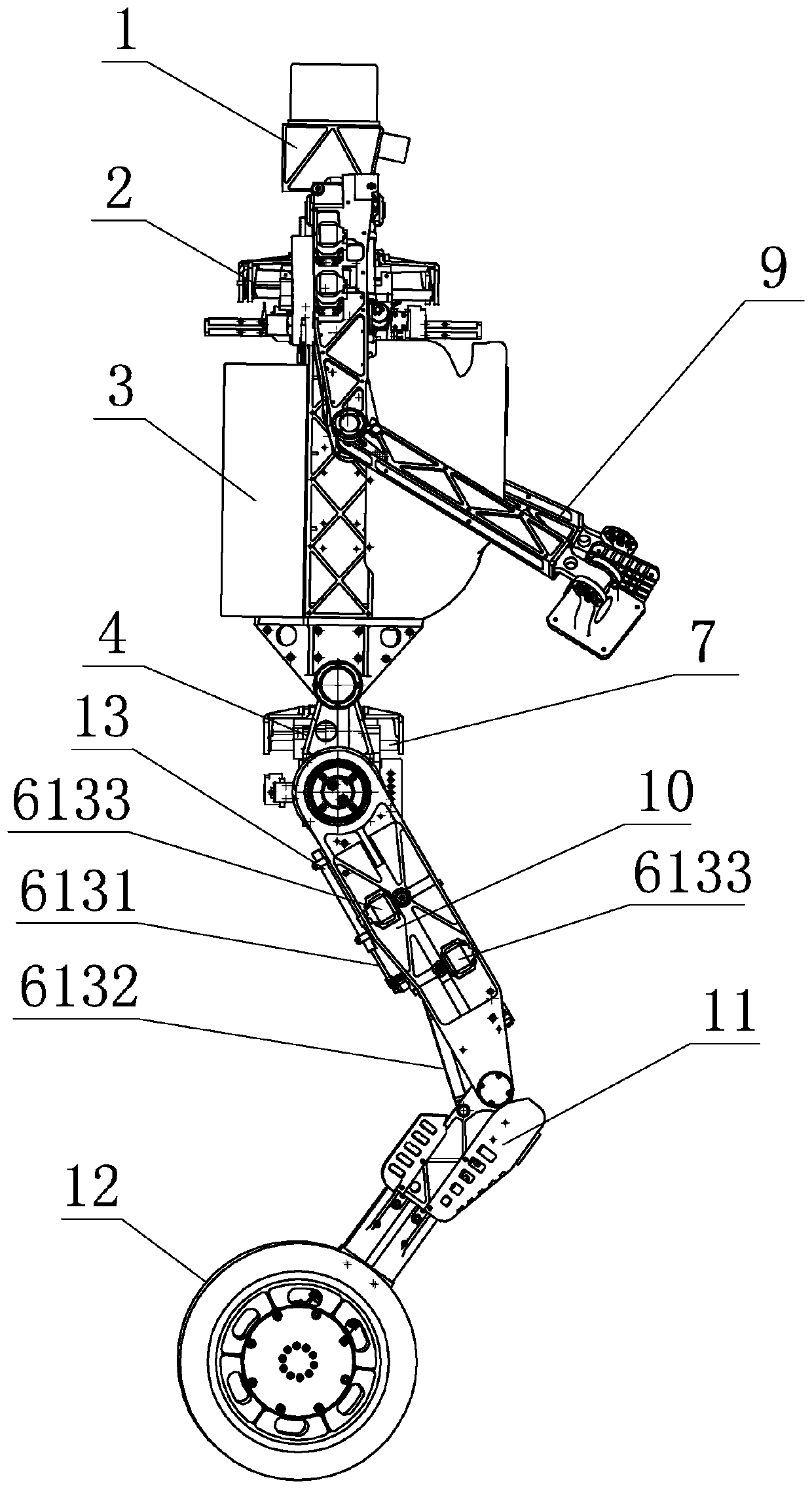

[0050] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, this embodiment includes a head 1, a shoulder 2, a body 3, a hip pelvis 4, a first hydraulic linkage assembly 5, a second hydraulic linkage assembly 6, and a third hydraulic linkage assembly 13. Hydraulic cylinder 7, two mechanical arms 9, two thighs 10, two shanks 11 and two driving wheels 12;

[0051] The head 1, the shoulder 2 and the body 3 are fixed together from top to bottom in sequence, the body 3 is hinged with the hip and pelvis 4 and driven by the hydraulic cylinder 7, and each mechanical arm 9 is hinged on the shoulder 2 and passed through the first The hydraulic link assembly 5 can be driven to swing left and right, each thigh 10 is hinged to the hip pelvis 4 and driven by the second hydraulic link assembly 6 so that each thigh 10 can swing back and forth, and each calf 11 is hinged to each thigh 10 And driven by the third hydraulic linkage assembly 13 so that ...

specific Embodiment approach 2

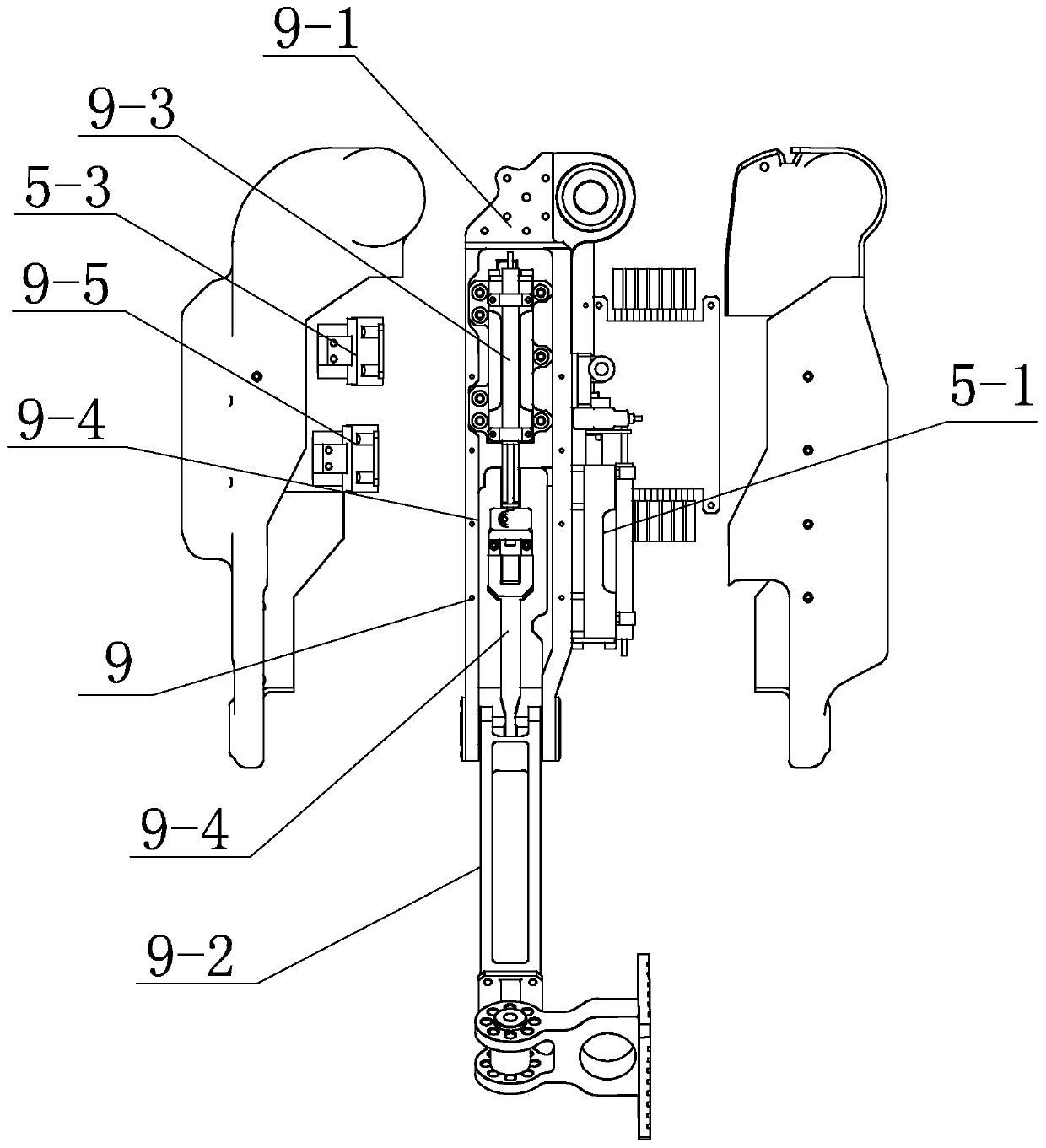

[0055] Specific implementation mode two: combination image 3 To illustrate this embodiment, each mechanical arm 9 in this embodiment includes a boom 9-1, a small arm 9-2, a third hydraulic cylinder 9-3, a third connecting rod 9-4 and a third hydraulic servo valve 9- 5;

[0056] The two booms 9-1 are hinged on both sides of the shoulder 2, the forearm 9-2 and the boom 9-1 are hinged together, and the third hydraulic cylinder 9-3 and the third hydraulic servo valve 9-5 are respectively fixed on On the boom 9-1, one end of the third connecting rod 9-4 is hinged with the forearm 9-2, and the other end of the third connecting rod 9-4 is hinged with the execution end of the third hydraulic cylinder 9-3 to make the forearm 9-2 swings on the big arm 9-1,

[0057] The big arm 9-1 and the shoulder 2 on each mechanical arm 9 are processed with a third oil circuit and a fourth oil circuit, and the oil outlet of the fourth oil circuit passes through the hydraulic pipe and the inlet of t...

specific Embodiment approach 3

[0059] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, the shoulder 2 of this embodiment is provided with two rotating shafts 2-1 and two swing arm hydraulic cylinders 2-2, and each swing arm hydraulic cylinder 2-2 communicates with an external hydraulic system through a hydraulic pipe. And each swing arm hydraulic cylinder 2-2 is provided with a hydraulic servo valve on the hose that communicates with the external hydraulic system, and each rotating shaft 2-1 is provided with a first gear 2-3, and each mechanical arm 9 passes through the first gear 2-3. An articulated shaft 15 is hinged to each rotating shaft 2-1 and driven by the first hydraulic linkage assembly 5 to swing left and right, each swing arm hydraulic cylinder 2-2 is fixed with a first guide rail, and the first rack 2-4 slides It is arranged on the first guide rail and fixed to the execution end of the swing arm hydraulic cylinder 2-2, and the first rack 2-4 and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com