Supersonic vibration multidimensional influence laser cladding device and method

A technology of laser cladding and ultrasonic vibration, which is applied in the direction of metal material coating process and coating, can solve the problems of complex design structure, large floor area, and ineffective use of ultrasonic auxiliary effects, so as to improve melting Covering performance and improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiment of the present invention will be further described below, but it is not used to limit the scope of the present invention:

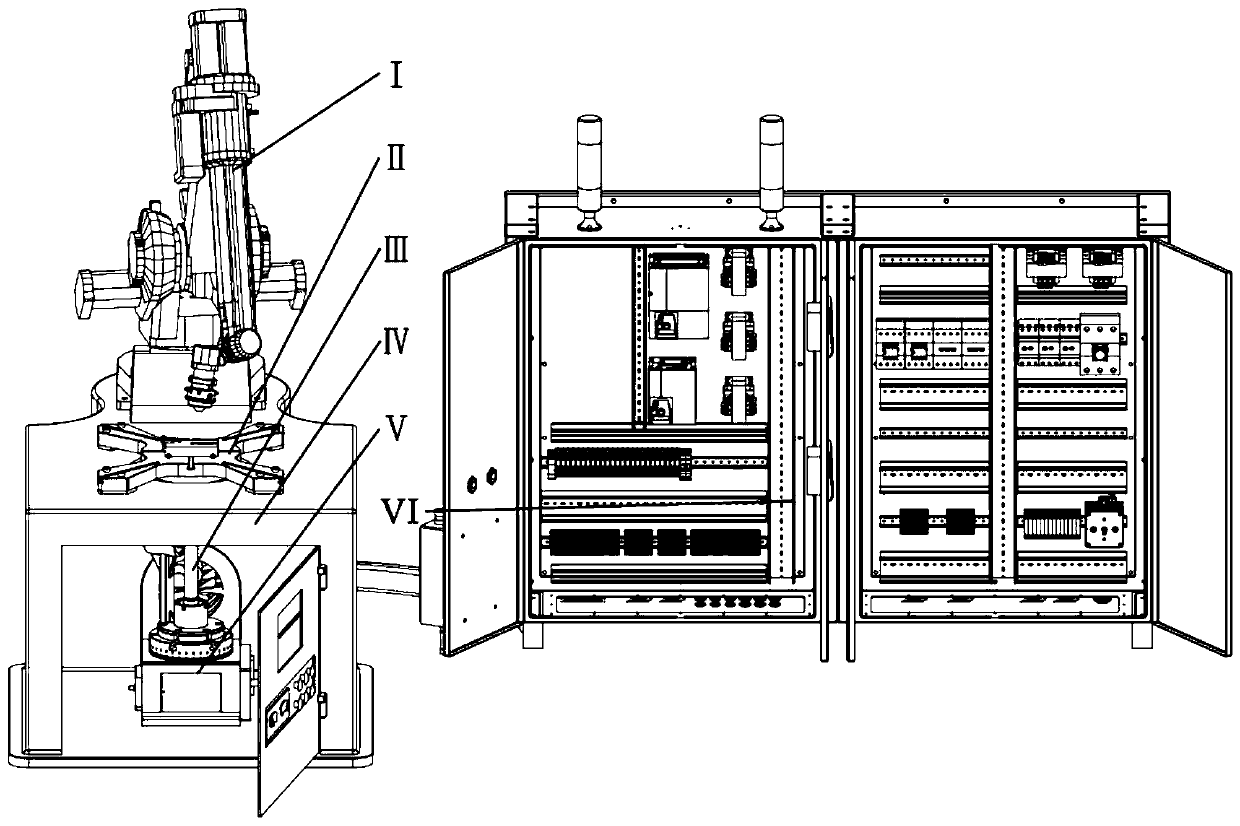

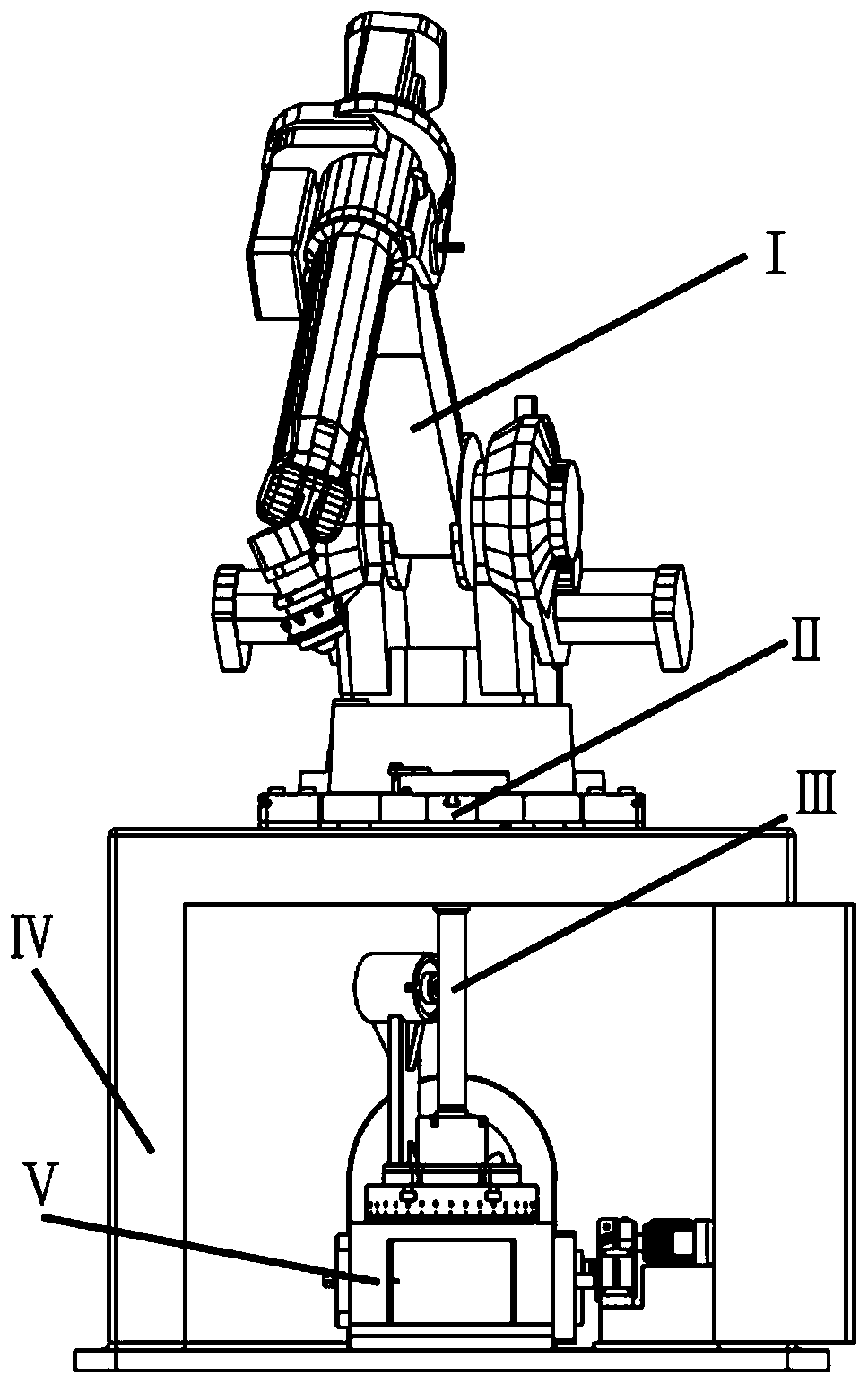

[0050] Such as figure 1 , figure 2 As shown, an ultrasonic vibration multi-dimensional influence laser cladding equipment includes manipulator part I, laser cladding part chuck part II, coupling ultrasonic system part III, frame IV, turntable system part V and system control cabinet VI. The control cabinet VI is electrically connected and controls the manipulator part I, the coupling ultrasonic system part III and the turntable system part V.

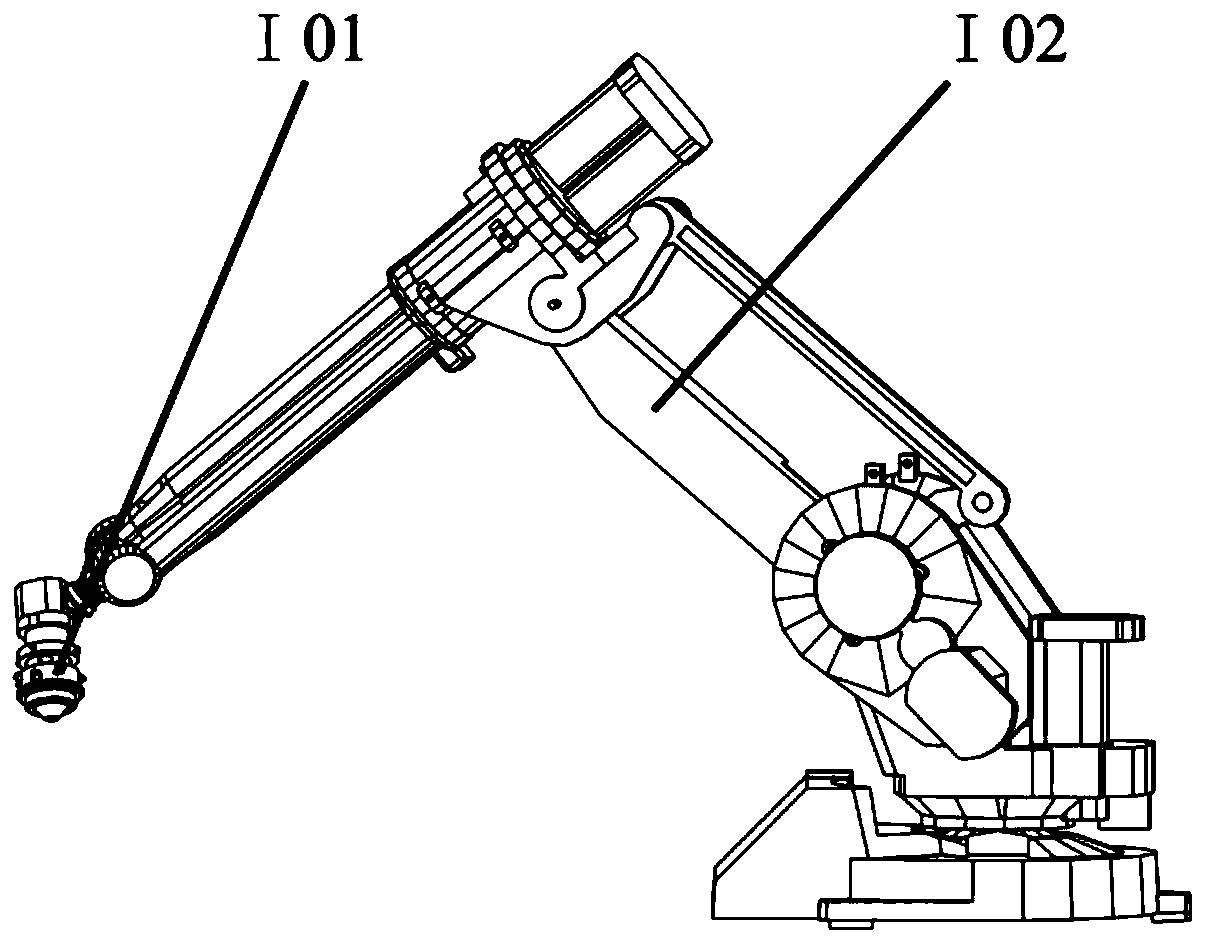

[0051] Such as image 3 As shown, the manipulator part I includes two parts: the coaxial laser cladding head I01 and the manipulator system I02. The laser cladding head I01 is fixed at the end of the manipulator, and the manipulator system I02 is fastened to the upper surface of the frame IV through its own base.

[0052] Such as Figure 4 , Figure 5 , Figure 6 As shown, clad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com