Construction process for lowering alkali reversion quality problem of building external wall

A technology for building exterior walls and quality problems, applied in construction, building structure, covering/lining, etc., can solve problems such as pointing out key points and requirements, and achieve prolonging service life, reducing alkali return phenomenon, and good resistance to alkali return. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

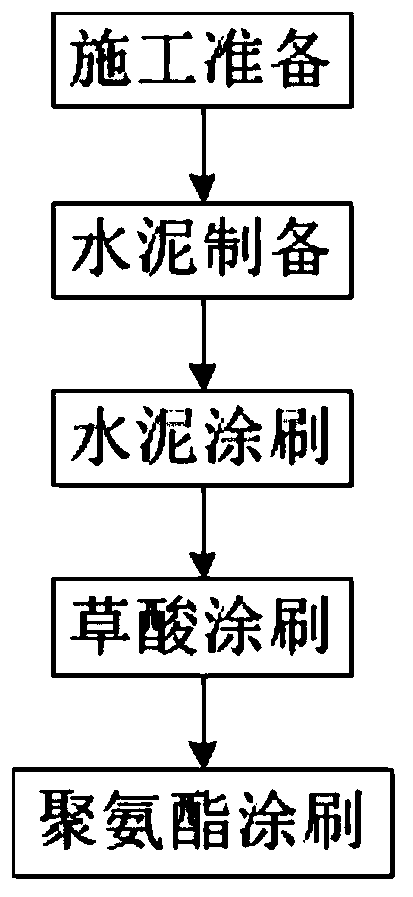

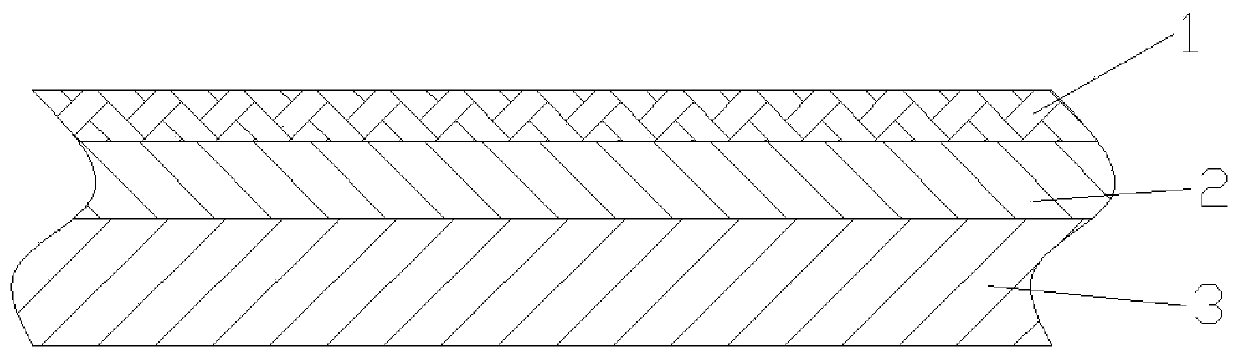

[0024] like Figure 1-2 As shown, a kind of construction technique that the present embodiment provides reduces the quality problem of alkali return of building exterior wall, concrete steps are:

[0025] (1) Construction preparations, preparation of construction materials, including low-alkali cement powder, sand, admixtures and alkali reversion inhibitors, while paying attention to weather conditions, avoiding construction in rainy, windy, low-temperature and other bad weather conditions;

[0026] (2) Cement 2 preparation, when preparing cement 2, strictly control the amount of water added in the mixing process of low-alkali cement powder and sand, add admixture and back-alkali inhibitor, low-alkali cement powder, sand, water, admixture and back-alkali The mass ratio of the inhibitor is 1:3:0.6:0.006:0.01;

[0027] (3) The cement 2 is painted. After the brushing is completed and before the cement 2 is dry, it cannot be in contact with water. When it is used as a ceramic til...

Embodiment 2

[0031] like Figure 1-2 As shown, the construction points of each step in a construction process to reduce the quality problem of building exterior wall alkali return are as follows:

[0032] The water used in steps (2) to (5) has a pH value of 7, which avoids the phenomenon of returning to alkali due to water quality.

[0033] The admixture added in step (2) is a naphthalene-based high-efficiency water reducer, specifically a naphthalenesulfonate formaldehyde condensate (produced by Anyang Shuanghuan Auxiliary Co., Ltd.), in order to prevent the prepared cement 2 from bleeding The alkali reversion inhibitor added is the Mei Ni brand QY9019 powder cement inhibitor produced by Beijing Wotu Building Materials Co., Ltd.

[0034] The concentration of oxalic acid painted in step (4) is lower than 5%, and the phenomenon of missing brushing is avoided. If the concentration of oxalic acid is higher than 5%, it will cause corrosion and other damage to ceramic tiles, external walls and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com