Handheld visual inspection device and pose detection method thereof

A visual inspection and inspection method technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of unsuitable real-time inspection, mechanical structure failure of limit function, and high hardware requirements, so as to improve inspection accuracy and inspection stability. , The effect of reducing the difficulty of use and reducing the cost of hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

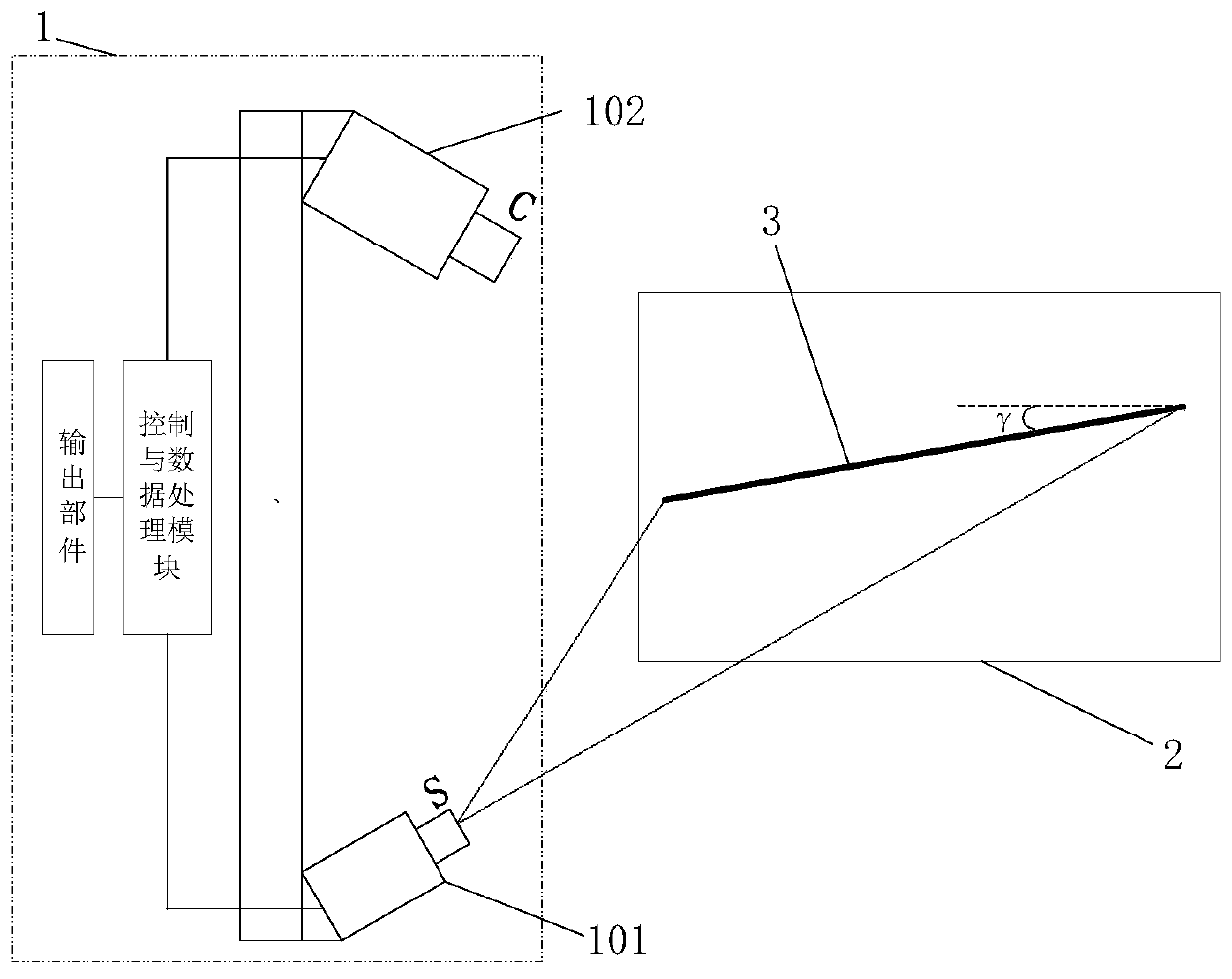

[0027] The posture detection method provided by the present invention is applicable to a handheld visual detection device 1, which includes a fixed laser 101 and a visual collection element 102; the laser 101 is used to project laser light to the surface of the object to be measured; the visual collection The element 102 is used to collect the image formed by the laser projected on the surface of the object to be measured; the laser 101 is a line laser or a point laser; when the laser is a point laser, the laser points projected on the surface of the object to be measured are on the same straight line.

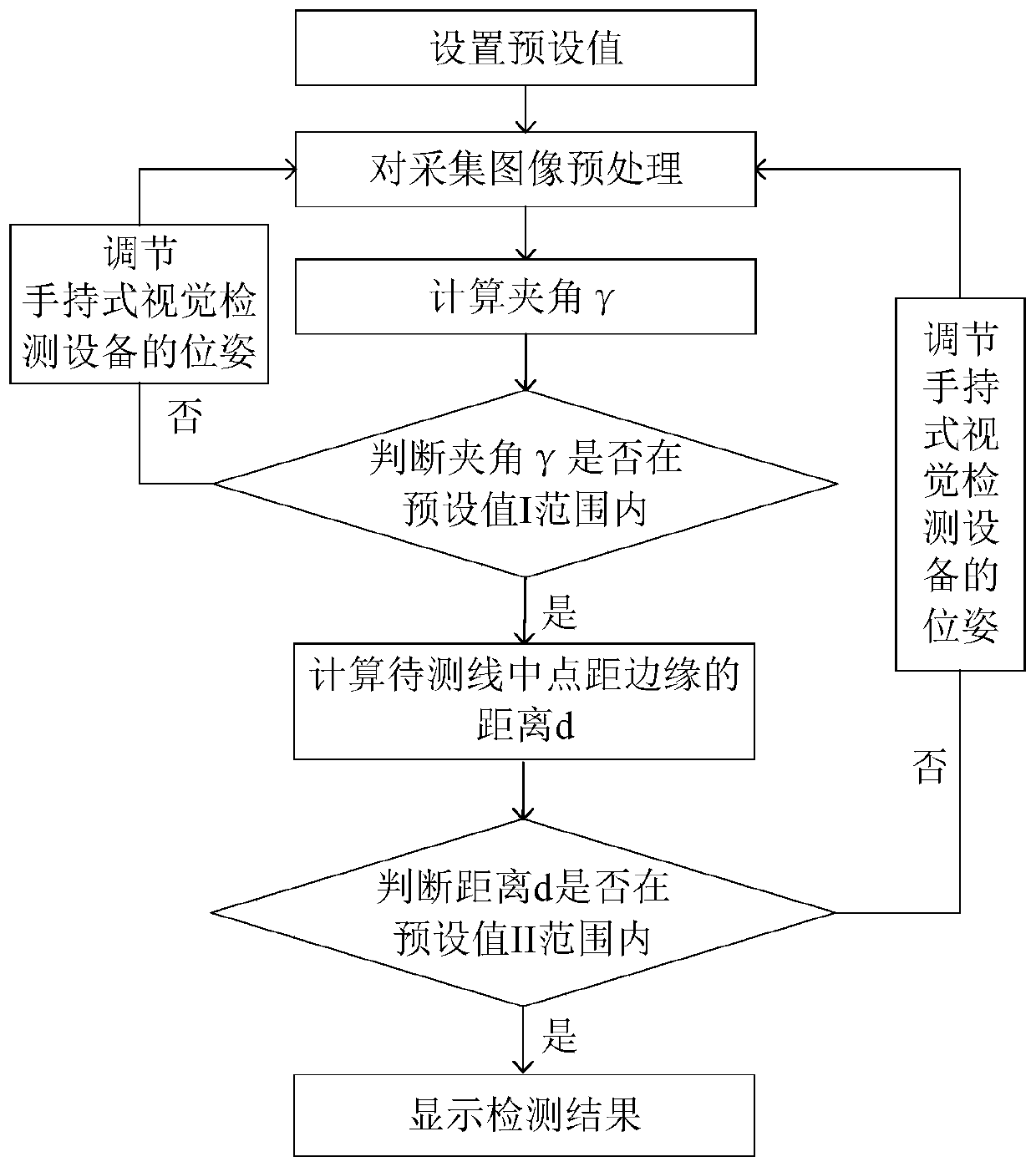

[0028] Before the detection, first set the preset value I and the preset value II, manually adjust the pose of the hand-held visual inspection device 1, the laser 101 projects a laser bar / laser point to the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com