X-ray detection device based on five-axis movement platform

A motion platform and detection device technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of poor stability, difficult scanning detection at large tilt angles, structural limitations, etc., to improve resolution imaging, improve detail resolution, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

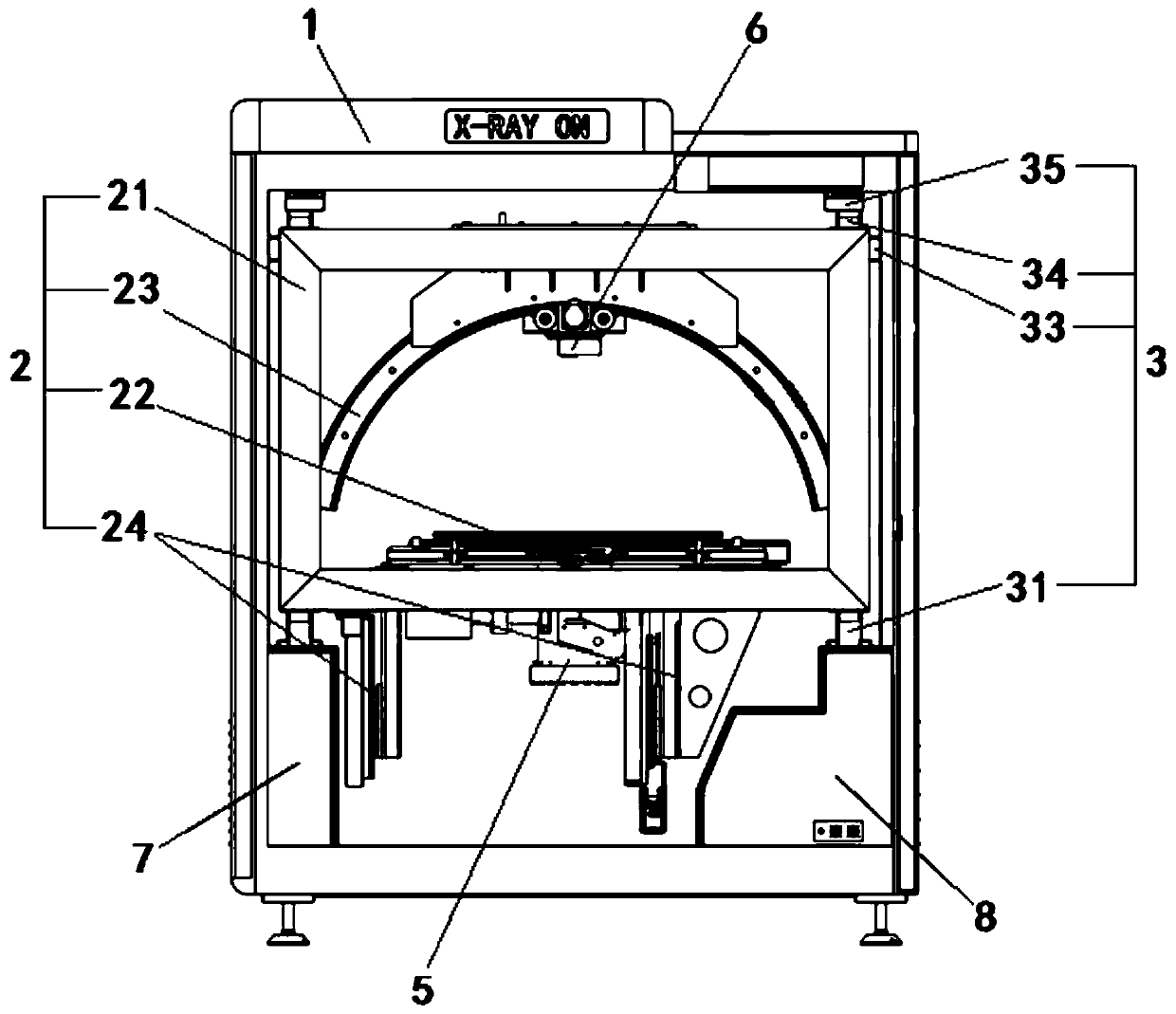

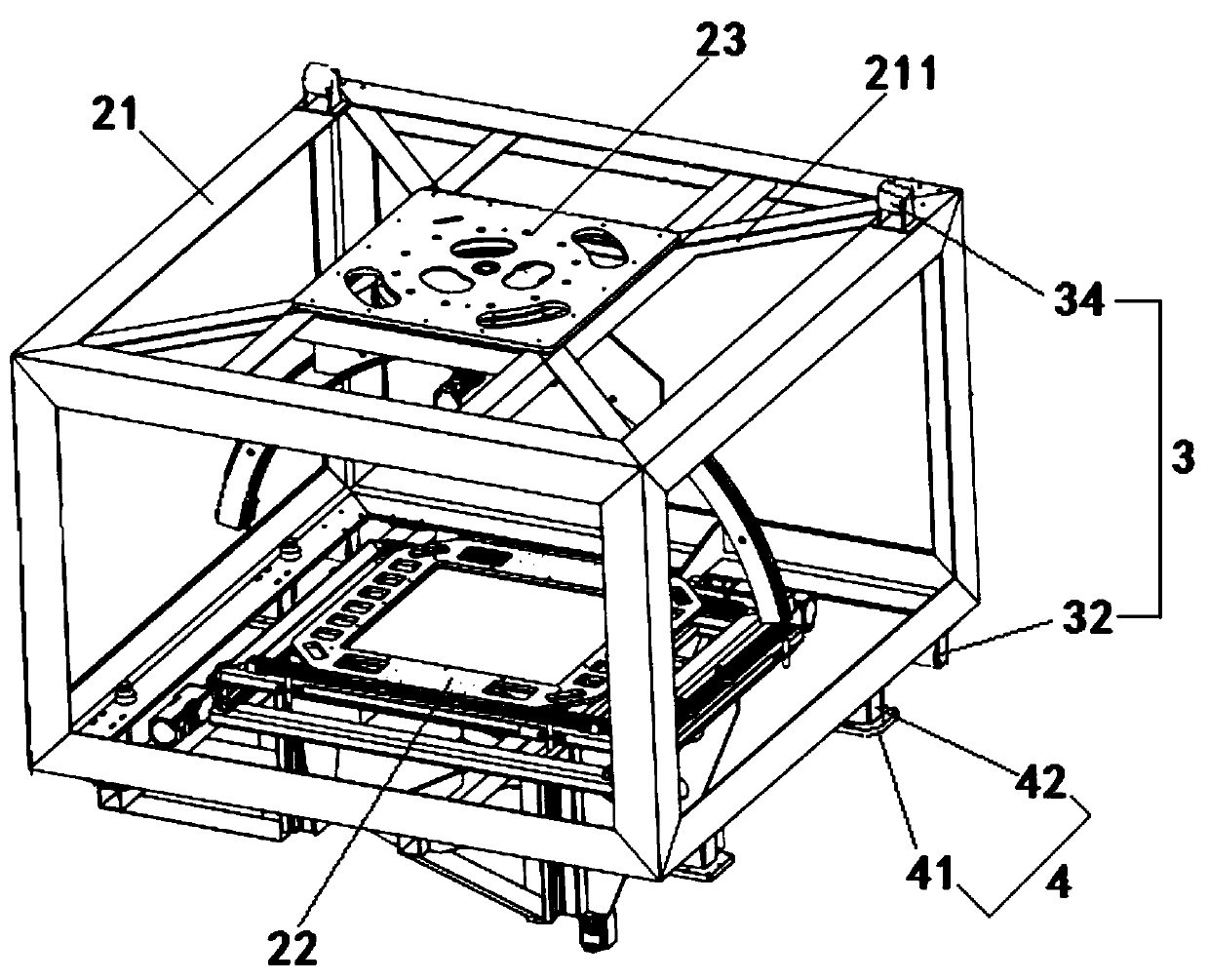

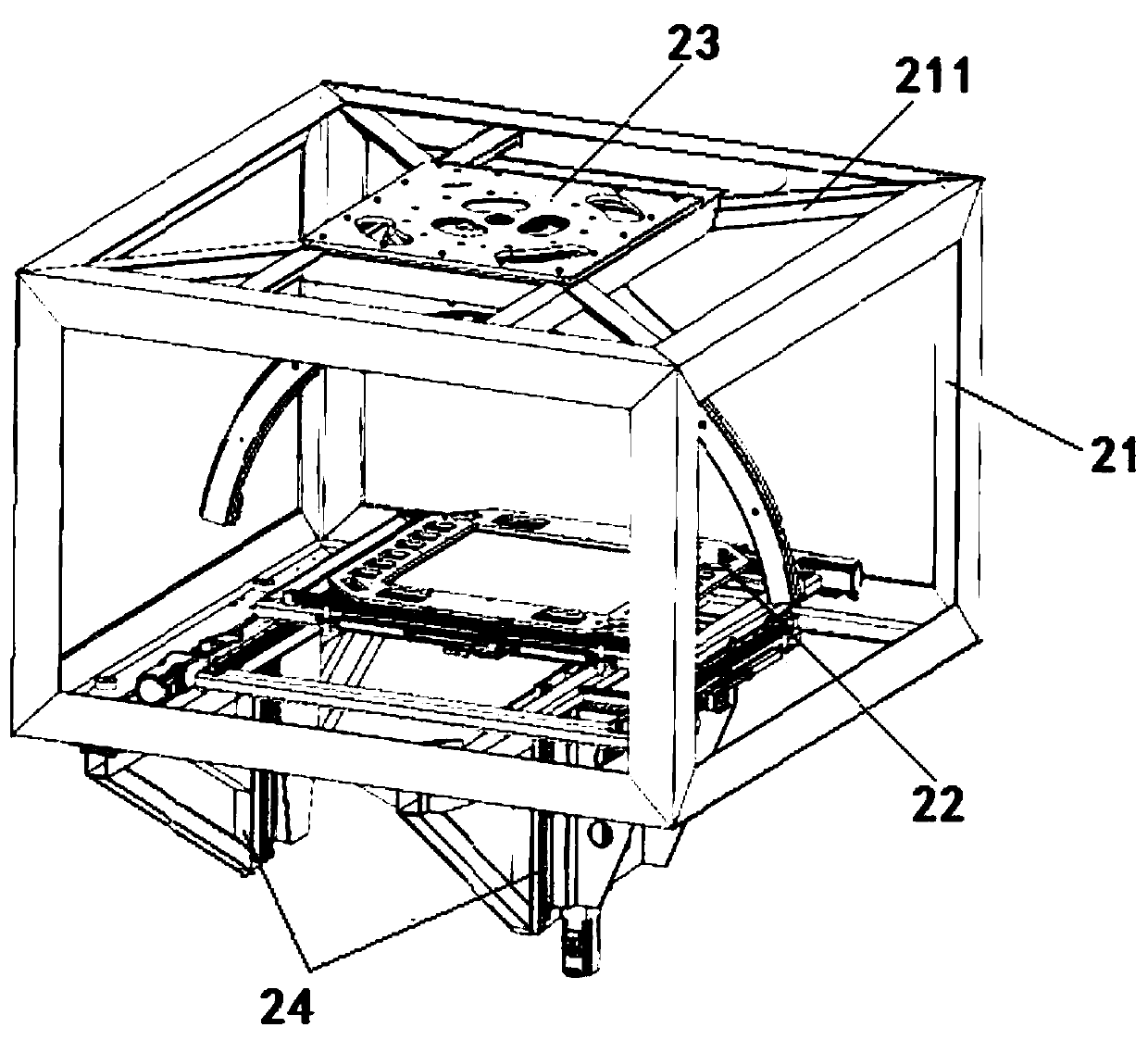

[0047] Such as figure 1 , figure 2 As shown, this embodiment discloses an X-ray detection device based on a five-axis motion platform, including a lead room 1, a five-axis motion platform 2, an installation assembly 4, an X-ray source assembly 5, a detector 6, and a motion control room 7 and the ray source control room 8; the five-axis motion platform 2 is arranged inside the lead room 1, and the five-axis motion platform 2 includes a rigid frame 21, a three-axis linear motion mechanism 22, a two-axis rotary motion mechanism 23 and a support assembly 24. The rigid frame 21 is a hollowed out square frame structure, the three-axis linear motion mechanism 22 is fixed on the inner bottom of the rigid frame 21 through the support assembly 24, and the two-axis rotary motion mechanism 23 is fixed on the The inner top of the rigid frame 21; the X-ray source assembly 5 is fixed on the three-axis linear motion mechanism 22, and the detector 6 is fixed on the two-axis rotary motion mec...

Embodiment 2

[0065] Such as figure 2 , Figure 4 , Figure 12As shown, the difference between this embodiment and the first embodiment is that a sliding mechanism 3 is also provided on the frame body of the rigid frame 21, and the upper surface, the side surface and the lower surface of the frame body of the rigid frame 21 are all passed through the sliding mechanism. Mechanism 3 is movably connected with the inner side wall of the lead room 1; the sliding mechanism 3 includes support wheels 31, travel wheels 32, side guide wheels 33, upper guide wheels 34 and guide grooves 35; the support wheels 31, travel wheels 32 , side guide wheel 33, upper guide wheel 34, guide groove 35 are all provided with two; Two described support wheels 31 are respectively fixed on the top front side of described motion control chamber 7 and the top front side of ray source control chamber 8 , the supporting wheels 31 are slidingly matched with the left and right sides of the bottom of the rigid frame 21; T...

Embodiment 3

[0068] Such as image 3 , Figure 5 , Figure 13 As shown, the difference between this embodiment and the first embodiment is that the rigid frame 21 is welded by structural steel and steel plate, and a vertical support plate 241 is arranged below it, and a pair of Z-axis guide rails are arranged on the vertical support plate 241. surface and Z-axis screw bearing mounting surface, there is a weight-reducing hole on the vertical support plate 241; a rotary support plate 211 is arranged above the rigid frame 21, and is rigidly connected with the upper mounting plate 2311 of the two-axis rotary motion mechanism 23, vertically The straight support plate 241 is welded on the lower side of the rigid frame 21, and the auxiliary vertical support plate 246 is installed on the other side below the rigid frame 21, parallel to the vertical support plate 241, and the vertical support plate 241 is connected to the vertical auxiliary support plate. There is a space between 246 for the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com